Beneficiation process to remove ferrotitanium from kaolin

A kaolin and process technology, applied in the field of kaolin ore beneficiation and removal of fine iron and titanium, can solve the problems of insignificant impurity removal effect and low efficiency, and achieve the effects of improving whiteness, overcoming energy barriers, and efficiently removing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

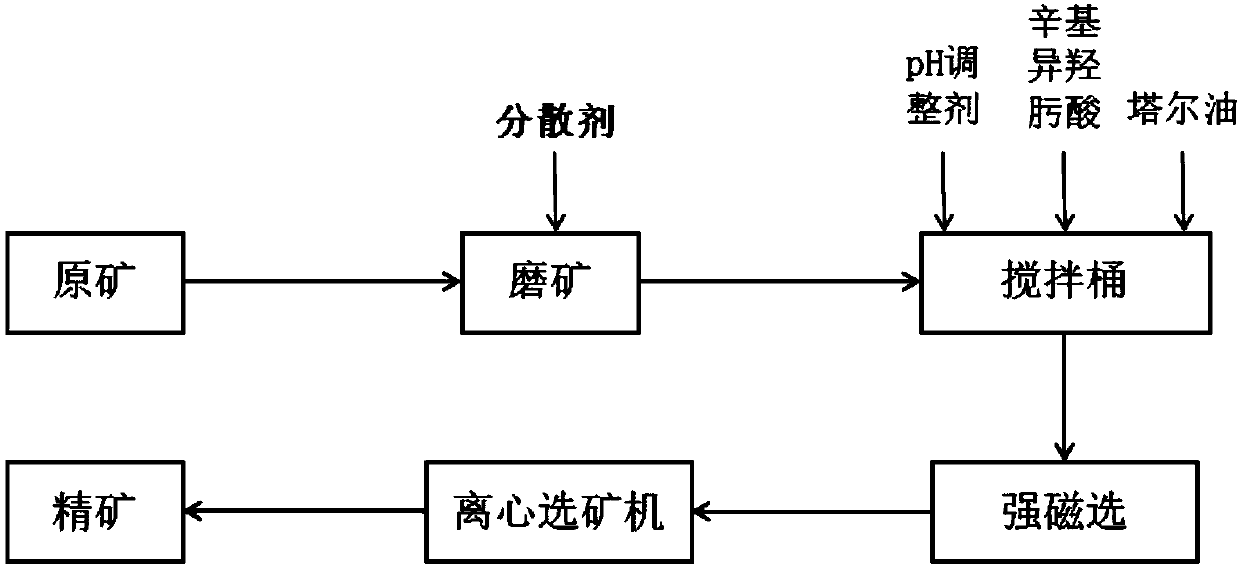

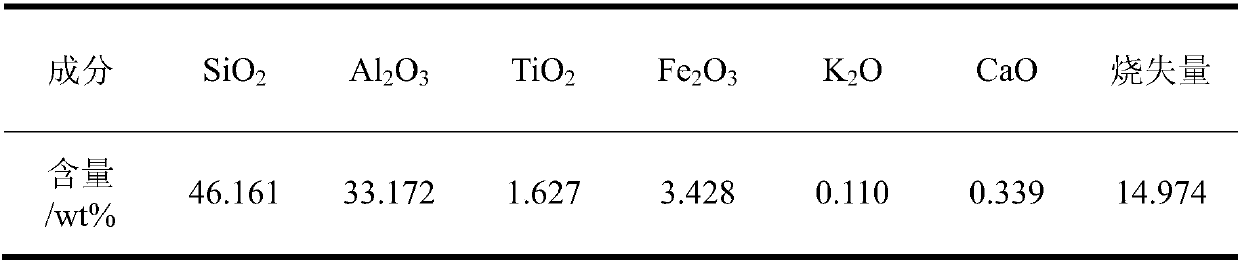

[0035] A kind of kaolin iron-removing titanium mineral processing technology, its flow chart is shown in figure 1 , including the following steps:

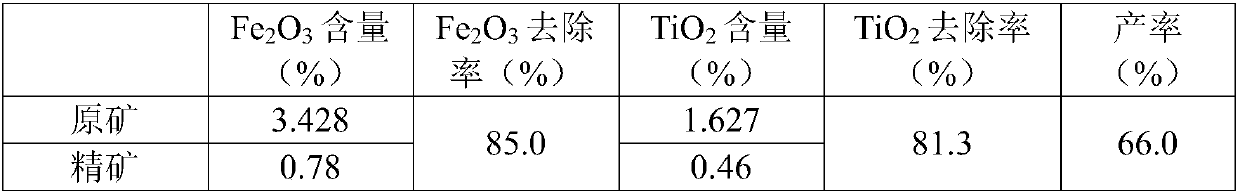

[0036] 1) Grinding kaolin raw ore (sodium hexametaphosphate is added as a dispersant during grinding) to -10μm content of 75%; 2) Put the obtained material into a slurry with a concentration of 65% and put it in a hexagonal mixing bucket with a baffle Stir; 3) Use a pH regulator to adjust the pH value of the pulp to 8; 4) Start the mixer, add 700g / t of octylhydroxamic acid at 1800rpm, then add 400g / t of tall oil and stir evenly; 5) Mixer Adjust to a suitable rotating speed of 4500rpm, and continue shearing and stirring for 25min; 6) after shearing and stirring, the obtained pulp is transferred to a strong magnetic separator with a magnetic field strength of 1.2T for sorting, and the flow rate of the pulp is 1cm / s; 7) the magnetic The obtained kaolin slurry is transferred to a centrifugal concentrator for gravity separation to obt...

Embodiment 2

[0041] A kind of kaolin iron-removing titanium mineral processing technology, specifically comprises the following steps:

[0042] 1) Grinding kaolin raw ore (adding polyacrylamide as a dispersant during grinding) to -10μm content of 80%; 2) Put the obtained material into a slurry with a concentration of 70% and put it in a hexagonal mixing bucket with a baffle for stirring ; 3) Adjust the pH value of the pulp to 7.5 by using a pH regulator; 4) Start the mixer, add 1000g / t of octyl hydroxamic acid at 2000rpm, then add 500g / t of tall oil and stir evenly; 5) adjust the mixer To the appropriate speed of 5500rpm, continue to shear and stir for 25min; 6) After shearing and stirring, transfer the obtained pulp to a magnetic separator with a magnetic field strength of 1.5T for separation, and the flow rate of the pulp is 1.5cm / s; 7) Magnetically separate The obtained kaolin slurry is transferred to a centrifugal concentrator for gravity separation to obtain kaolin concentrate, wherei...

Embodiment 3

[0047] A kind of kaolin iron-removing titanium mineral processing technology, specifically comprises the following steps:

[0048]1) Grinding kaolin raw ore (adding water glass as a dispersant during grinding) to -10 μm content of 70%; 2) mixing the obtained material into a slurry with a concentration of 60% and putting it into a hexagonal mixing bucket with a baffle for stirring; 3) Use a pH regulator to adjust the pH value of the pulp to 7; 4) Start the mixer, add 400g / t of octyl hydroxamic acid at 1500rpm, then add 250g / t of tall oil and stir evenly; 5) Adjust the mixer to Suitable rotating speed is 3500rpm, continuous shearing and stirring for 20min; 6) After shearing and stirring, the obtained pulp is transferred to a strong magnetic separator with a magnetic field strength of 1.0T for separation, and the flow rate of the pulp is 0.75cm / s; 7) Magnetic separation The obtained kaolin slurry is transferred to a centrifugal concentrator for gravity separation to obtain kaolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com