Inorganic noiseless artificial slabstone production system and technology

A production system, technology of artificial stone slabs, applied in the direction of manufacturing tools, ceramic forming machines, forming pressure heads, etc., can solve the problems of low production efficiency, poor decorative effect and usability of cement-based artificial stone, and difficulty in meeting decorative design requirements. Achieve the effect of reducing dust pollution and noise pollution, smooth and bright surface, and dense texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings. It should be noted that this embodiment is descriptive, not restrictive, and cannot thereby limit the protection scope of the present invention.

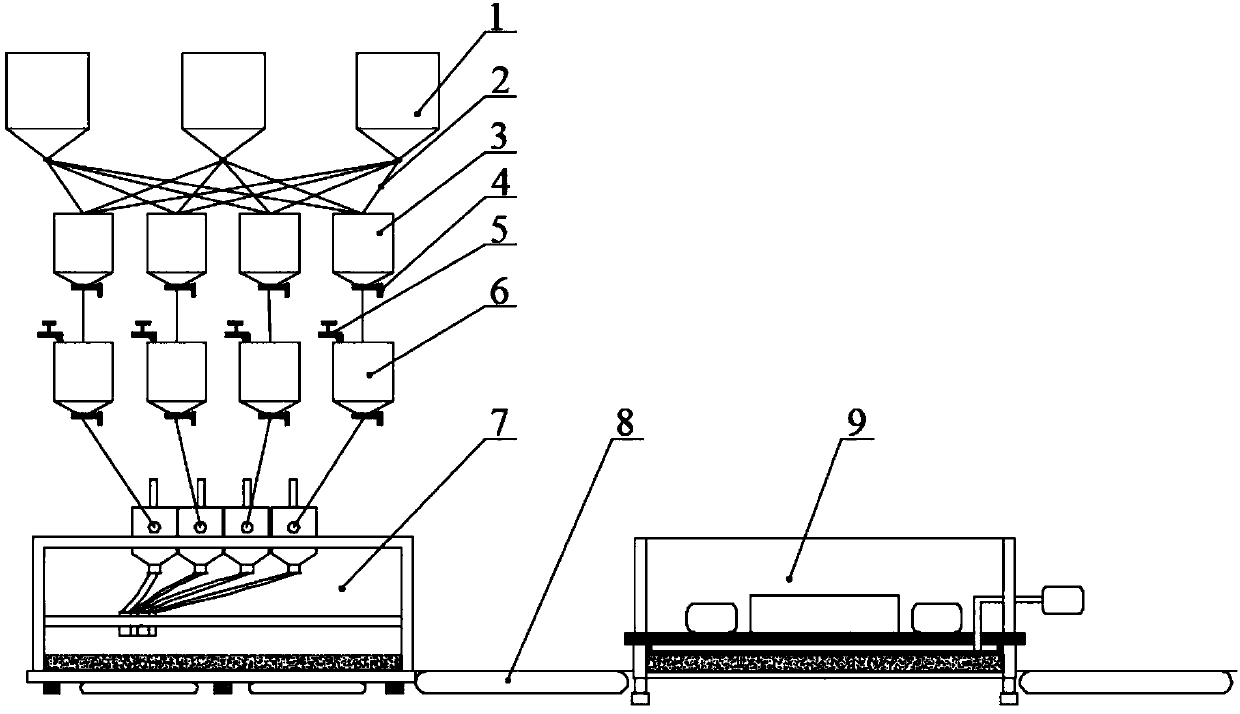

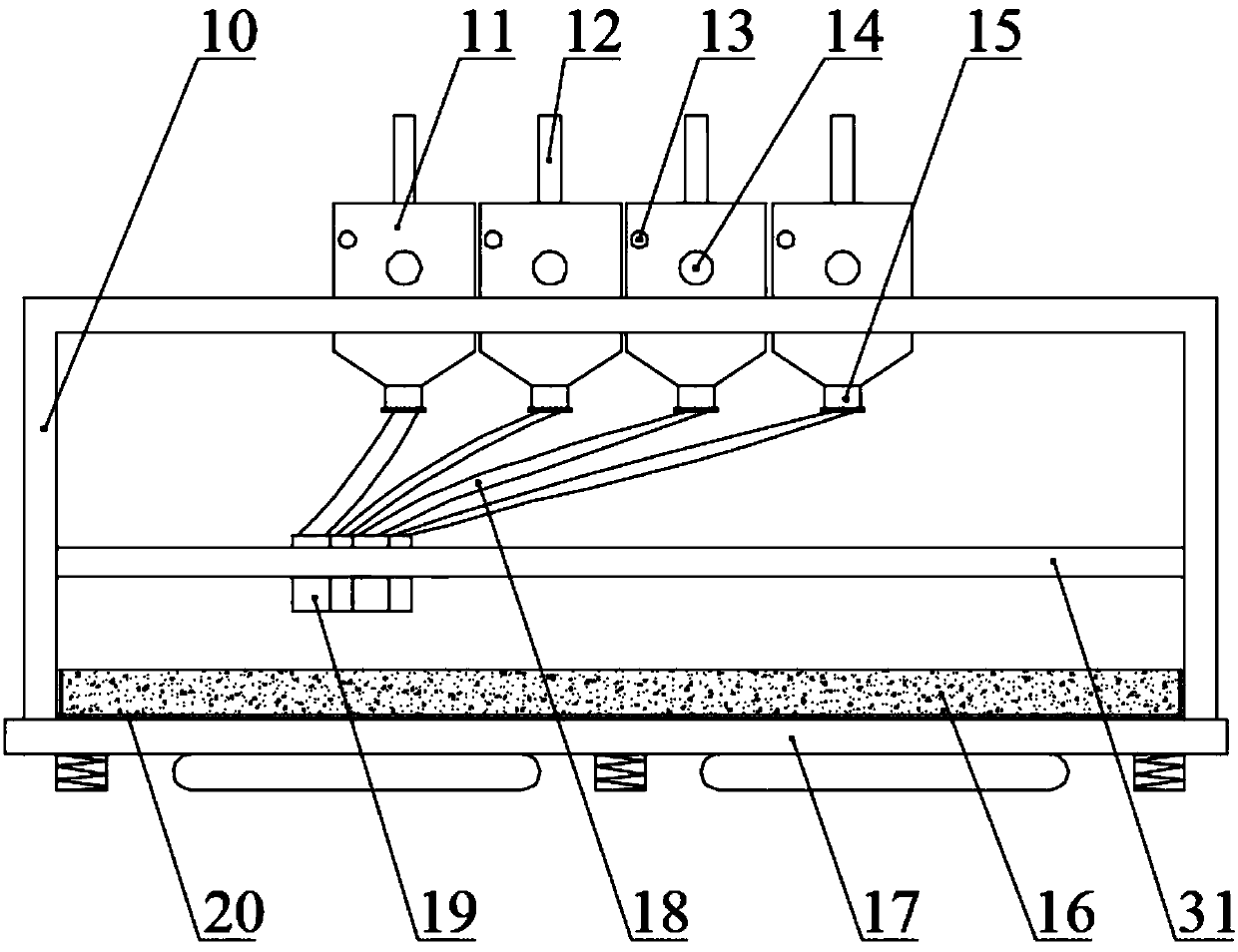

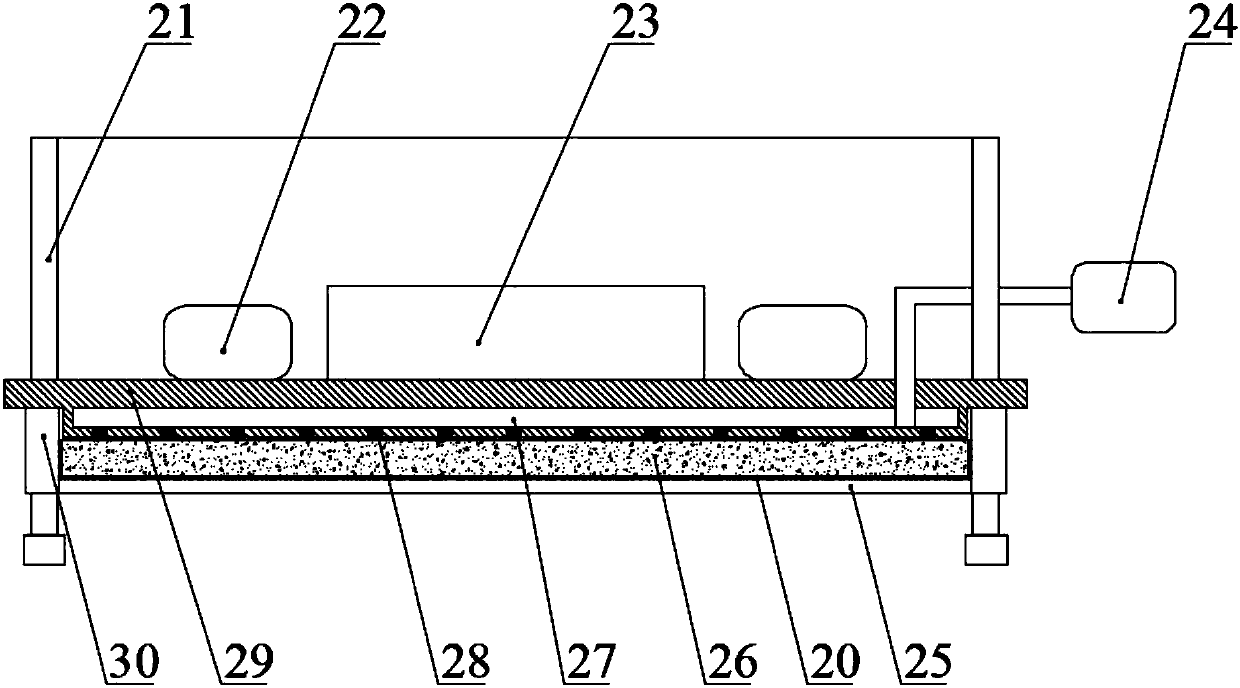

[0037] A production system for inorganic and noiseless artificial stone slabs, the production system includes a vacuum press machine 9, and a raw material tank 1, a bucket weighing scale 3, a vacuum mixing tank 6 and a distributing machine 7 connected in sequence by a sealed conveying device, and the raw material is dried from the raw material Quantitatively convey the inside of the tank to the bucket weighing scale for weighing, then send the dry raw materials into the vacuum mixing tank, add water and stir to make slurry 16, then send the slurry into the distribution machine to make slurry board 26, and finall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com