Production line of rotating disc type loose core die composite board

A composite board and production line technology, applied in the direction of layered products, lamination devices, lamination auxiliary operations, etc., can solve the problems that the opening and closing of the mold is manual operation, unresolved, and difficulty in taking out the composite board, so as to facilitate automated production, The effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

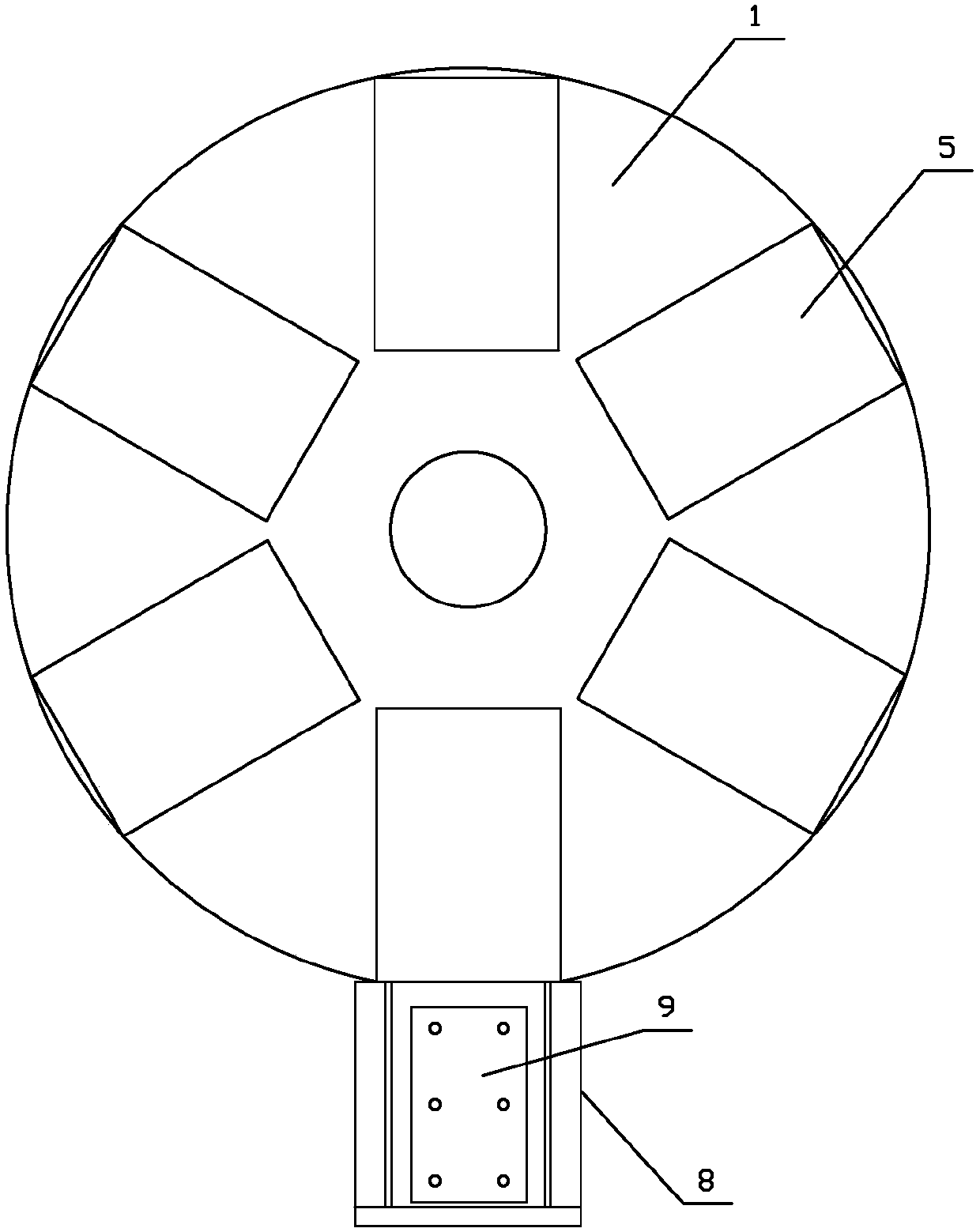

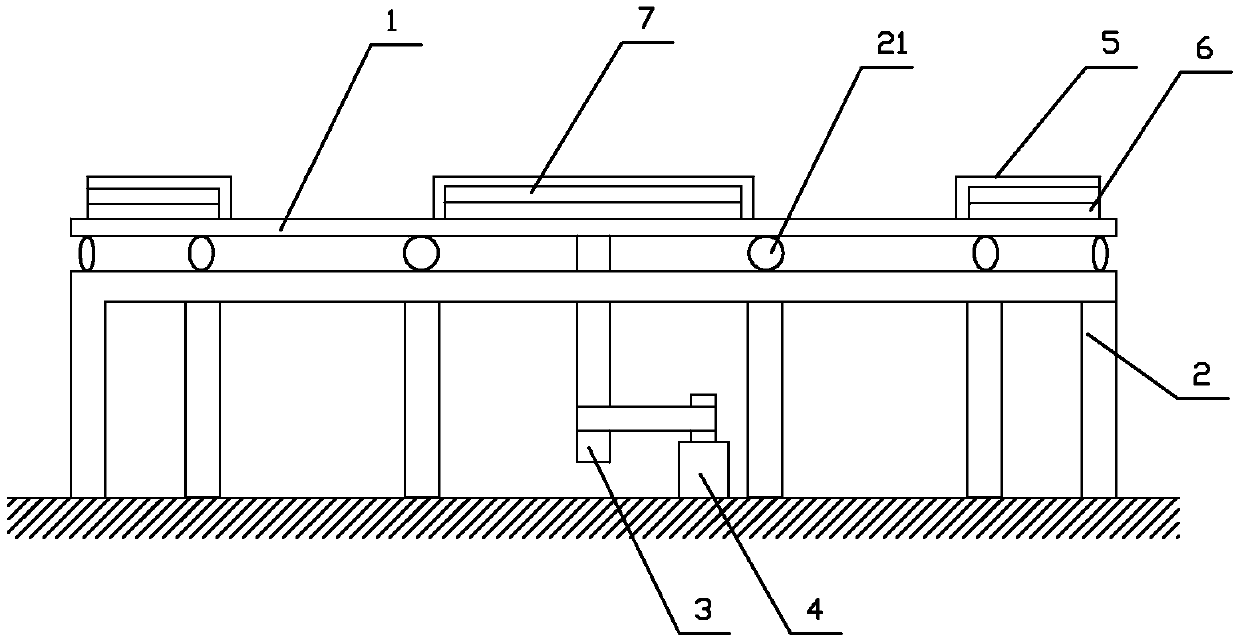

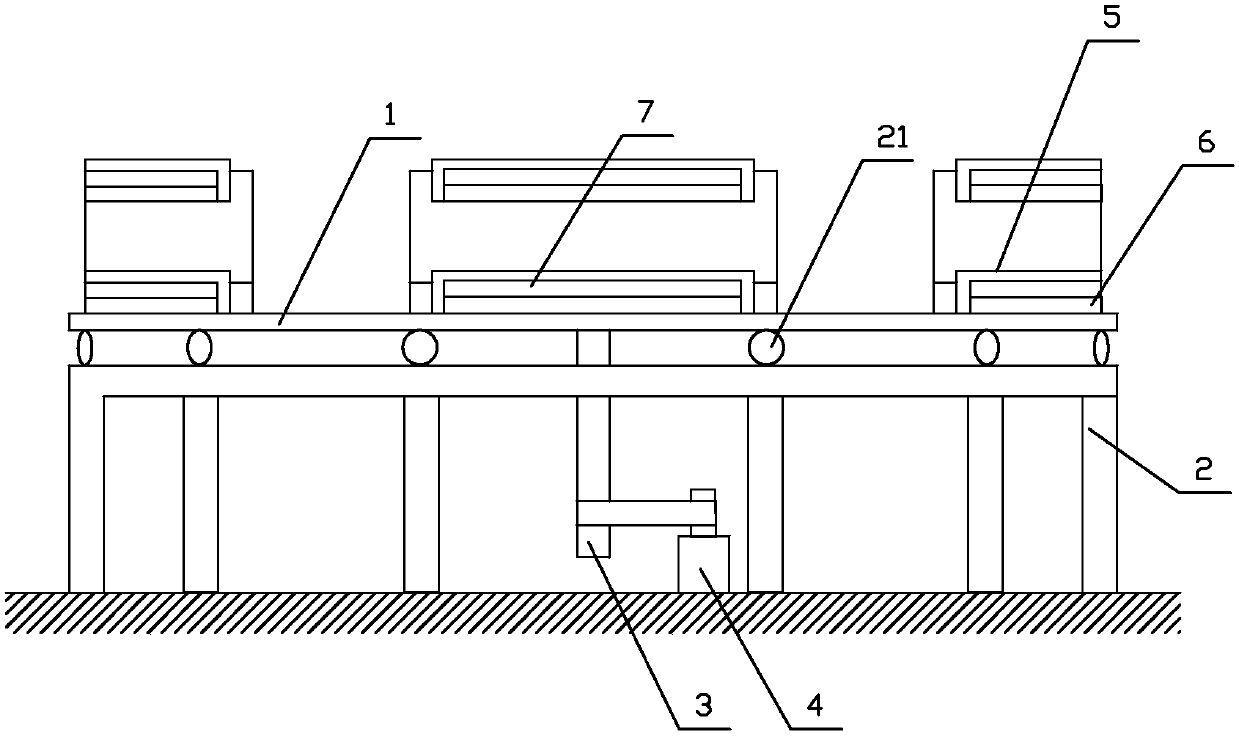

[0025] Such as Figure 1-7 As shown in the figure, a turntable-type living core mold composite board production line includes a disc 1, a number of outriggers 2 are arranged around the disc 1, and the outriggers 2 are connected to the disc 1 in movable abutment, and a rotating disc is provided under the disc 1. Power mechanism, several layers of movable core molds 5 are evenly distributed along the circumference on the upper surface of the disc 1, the end of the movable core mold 5 away from the disc 1 is provided with a mold opening 7, and a mold opening 7 is provided in the movable core mold 5 to enter and exit through the mold opening 7. The movable frame 6 of the movable core mold 5 is provided with at least one support 8 on the side of the disc 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com