A kind of epoxy resin adhesive film and preparation method thereof

An epoxy resin glue, epoxy resin technology, applied in the field of composite materials, can solve the problems of poor mechanical properties such as toughness and strength, unable to meet actual needs, unfavorable for large-scale production, etc., to achieve superior performance, strong toughness and enhancement , the effect of improving toughness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

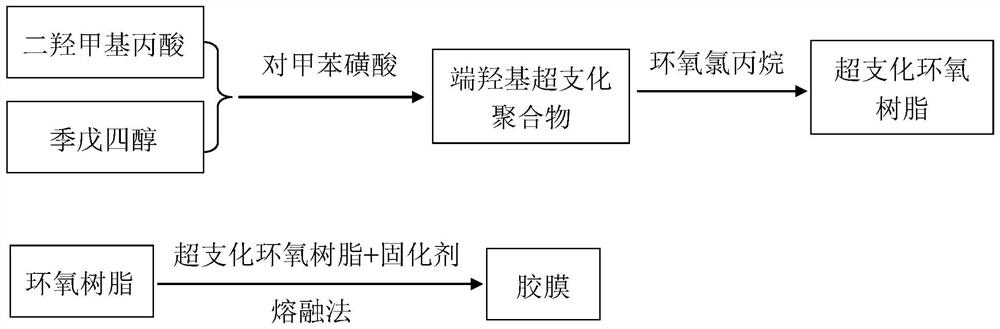

[0022] In the preparation method of a high-performance adhesive film provided by the invention, the hyperbranched epoxy resin is used as an additive, which effectively improves the mechanical strength of the epoxy resin. The present invention uses dihydroxypropionic acid as a monomer, pentaerythritol as a nucleus, and toluene as a solvent, adds catalyst A, reacts, and removes the solvent to obtain a hydroxyl-terminated hyperbranched polymer; wherein, the content of the dihydroxypropionic acid and the pentaerythritol The molar ratio is 4-60:1; the catalyst A is p-toluenesulfonic acid with a mass fraction of 2%; the reaction time is 10-14 hours, and the reaction temperature is 110-130°C.

[0023] Add a hydroxyl-terminated hyperbranched polymer and epichlorohydrin into a reaction vessel for a ring-opening reaction, add catalyst B, and perform a ring-closing reaction to obtain a hyperbranched epoxy resin; wherein the reaction vessel is a three-necked flask; the terminal hydroxyl T...

Embodiment 1

[0026] Using dihydroxypropionic acid with a substance ratio of 4:1 as a monomer, pentaerythritol as a nucleus, and toluene as a solvent, add 2% p-toluenesulfonic acid, react at 110°C for 10 hours, remove the solvent to obtain hyperbranched polymerization of terminal hydroxyl groups thing;

[0027] Add a hydroxyl-terminated hyperbranched polymer and epichlorohydrin with a functional group ratio of 1:5 in a three-necked flask, and perform a ring-opening reaction at 130°C for 10 hours, add 10% sodium hydroxide solution, and perform a ring-closing reaction at 0°C for 5 hours to obtain hyperbranched epoxy resin;

[0028] Mix 128 epoxy resin, hyperbranched epoxy resin and diaminodiphenyl sulfone with a mass ratio of 100:9:70, and prepare an epoxy resin adhesive film by melting method;

[0029] The adhesive film was simply laminated, cured at 80°C for 2 hours, and the mechanical properties were measured.

Embodiment 2

[0031] Using dihydroxypropionic acid with a substance ratio of 12:1 as the monomer, pentaerythritol as the core, and toluene as the solvent, add 2% n-butyl titanate, react at 120°C for 12 hours, remove the solvent to obtain terminal hydroxyl hyperbranching polymer;

[0032] Add a hydroxyl-terminated hyperbranched polymer and epichlorohydrin with a functional group ratio of 1:6 in a three-necked flask, and perform a ring-opening reaction at 130°C for 6h, add 15% sodium hydroxide solution, and perform a ring-closing reaction at 5°C for 7h to obtain hyperbranched epoxy resin;

[0033] Mix 128 epoxy resin, hyperbranched epoxy resin and diaminodiphenyl sulfone with a mass ratio of 100:9:90, and prepare an epoxy resin adhesive film by melting method;

[0034] The adhesive film was simply laminated, cured at 100°C for 3 hours, and the mechanical properties were measured.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com