A method for preparing β-gallium oxide thin film on silicon substrate

A gallium oxide, silicon substrate technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as easy cracks and poor film quality, and achieve the effects of eliminating cracks, low cost, and simple process methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

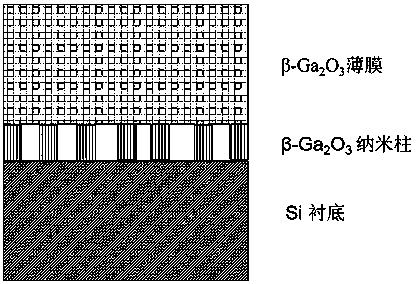

Image

Examples

specific Embodiment approach 1

[0022] Specific implementation mode 1: This implementation mode records a method for preparing a β-gallium oxide thin film on a silicon substrate, and the steps of the method are as follows:

[0023] Step 1: Prepare GaOOH seed layer by water bath method;

[0024] Get a silicon substrate, and it is cleaned, stand-by; Water bath method configures gallium nitrate (Ga(NO 3 ) 3 ) and hexamethylenetetramine (HMT) mixed solution, and the growth surface of the substrate used is placed in the mixed solution for growth; wherein, the concentration of gallium nitrate is 0.1~0.6mol / L, and the concentration of hexamethylenetetramine is 0.5~1mol / L, the total volume of the mixed solution is 30 mL, the temperature of the water bath is 80-98 o C, the growth time is 1-3h;

[0025] Step 2: After washing the substrate with the seed layer obtained in Step 1 with deionized water, put it into an oven at 150 o Dry at C temperature, then put it into the hydrothermal mixed solution to react, after t...

Embodiment 1

[0033] A method for preparing a β-gallium oxide thin film on a silicon substrate, the steps of the method are as follows:

[0034] Step 1: Prepare GaOOH seed layer by water bath method;

[0035] Get a silicon substrate, and it is cleaned, stand-by; Water bath method configures gallium nitrate (Ga(NO 3 ) 3 ) and hexamethylenetetramine (HMT) mixed solution, place the substrate growth side down in the mixed solution for growth; wherein, the concentration of gallium nitrate is 0.5mol / L, and the concentration of hexamethylenetetramine is 0.5mol / L, the total volume of the mixed solution is 30 mL, and the temperature of the water bath is 90 o C, the growth time is 3h;

[0036] Step 2: After washing the substrate with the seed layer obtained in Step 1 with deionized water, put it into an oven at 150 o Dry at C temperature, then put it into the hydrothermal mixed solution to react, after the reaction, cool down naturally, take out the substrate, wash it with deionized water, and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com