High-temperature alloy additive manufacturing method

A superalloy and additive manufacturing technology, applied in the directions of additive manufacturing, additive processing, and energy efficiency improvement. Improve the comprehensive mechanical properties, the effect of high complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

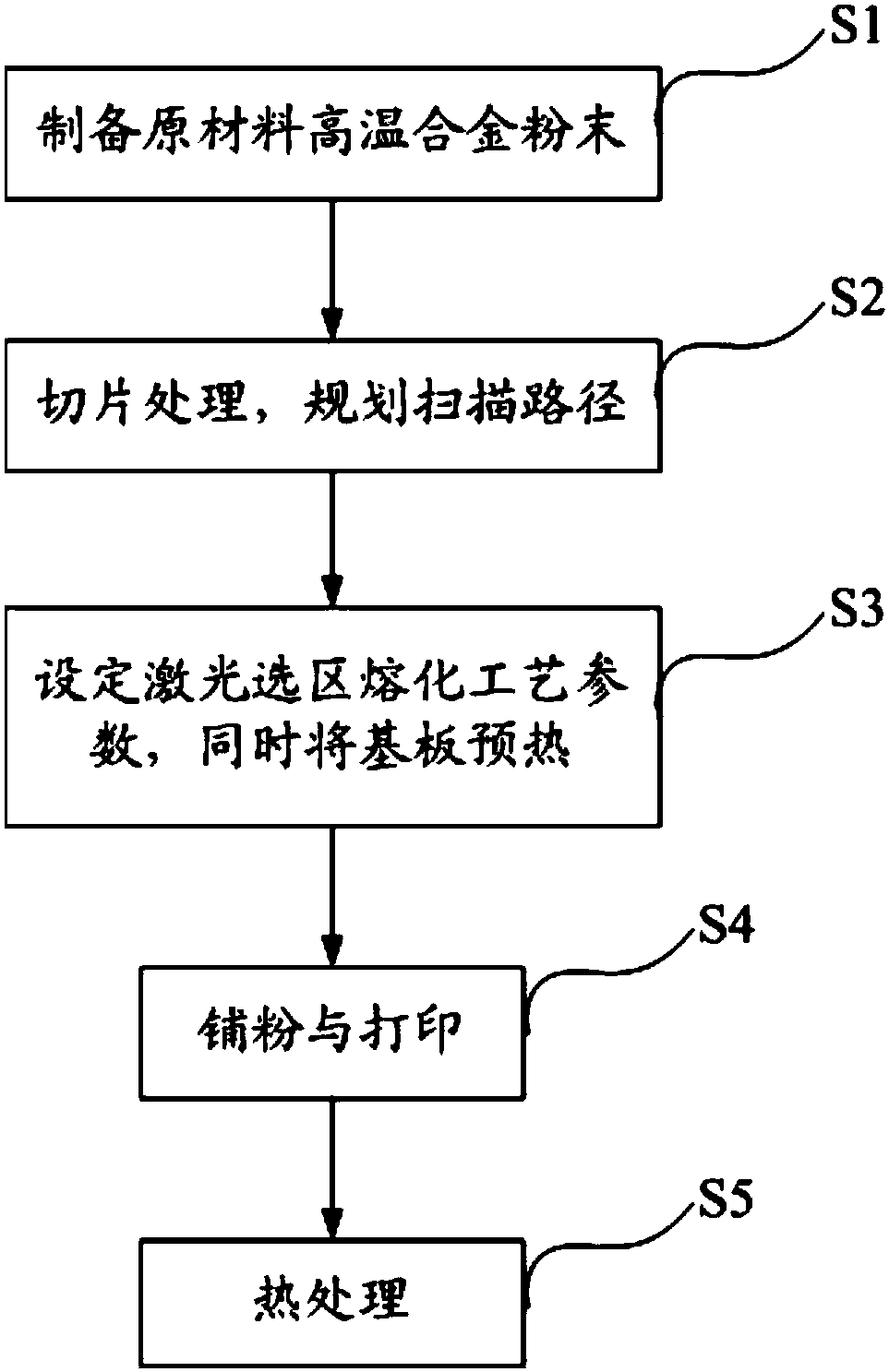

Method used

Image

Examples

Embodiment 1

[0041] (1) The material is IN939 superalloy powder, the powder particle size range is 15-53μm, where d 10 Controlled at 18μm, d 50 Controlled at 30μm, d 90 Controlled at 45μm;

[0042] (2) Slice the three-dimensional model of the part to be formed, with a slice thickness of 15 μm; plan the scanning path of the component, use the nine-square grid method to scan, the area size is 4*4mm, and the deflection angle when scanning layer by layer, the deflection angle is 36°;

[0043] (3) Laser selective melting equipment adopts a combination of vacuuming and replacement. Firstly, the vacuum is pumped to 80KPa, and then high-purity Ar gas is filled into the molding chamber, and the replacement is repeated several times until the oxygen content of the molding chamber is lower than 100ppm and the pressure is maintained. Start printing at 30mbar; avoid powder oxidation;

[0044] Selective laser melting process: the laser power for scanning the entity is 300W, the laser power for scanni...

Embodiment 2

[0050] (1) The material is IN939 superalloy powder, the powder particle size range is 15-53μm, where d 10 Controlled at 21μm, d 50 Controlled at 33μm, d 90 Controlled at 48μm;

[0051] (2) Slice the 3D model of the part to be molded, with a slice thickness of 25 μm; plan the scanning path of the component, use the nine-square grid method to scan, the area size is 4*4mm, and the deflection angle is 37° when scanning layer by layer;

[0052] (3) Laser selective melting equipment adopts a combination of vacuuming and replacement. Firstly, the vacuum is pumped to 80KPa, and then high-purity Ar gas is filled into the molding chamber, and the replacement is repeated several times until the oxygen content of the molding chamber is lower than 100ppm and the pressure is maintained. Start printing at 30mbar;

[0053] Selective laser melting process: the laser power for scanning the entity is 350W, the laser power for scanning the contour is 180W, the laser power for the support is 350W...

Embodiment 3

[0059] (1) The material is IN939 superalloy powder, the powder particle size range is 15-53μm, where d 10 Controlled at 24μm, d 50 Controlled at 36μm, d 90 Controlled at 51μm;

[0060] (2) Slicing the 3D model of the part to be formed, with a slice thickness of 30 μm; planning the scanning path of the component, using the nine-square grid method to scan, the area size is 4*4mm, and the deflection angle when scanning layer by layer, the deflection angle is 40°;

[0061] (3) Laser selective melting equipment adopts a combination of vacuuming and replacement. Firstly, the vacuum is pumped to 80KPa, and then high-purity Ar gas is filled into the molding chamber, and the replacement is repeated several times until the oxygen content of the molding chamber is lower than 100ppm and the pressure is maintained. Start printing at 30mbar;

[0062] Selective laser melting process: the laser power for scanning the entity is 400W, the laser power for scanning the contour is 200W, the las...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluidity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com