Anti-corrosion graphene coating and preparation method thereof

An anti-corrosion coating, graphene technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings and other directions, can solve the problems of poor resistance to strong corrosive media, poor weather resistance, coating cracking, etc., to achieve stable performance, low product price, Strong sticky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The production process of the present invention:

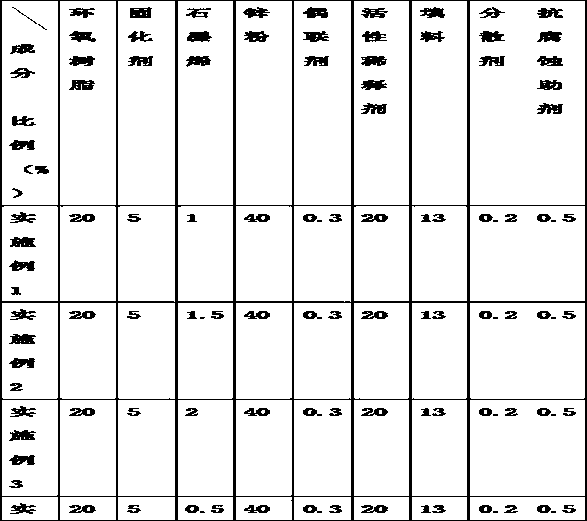

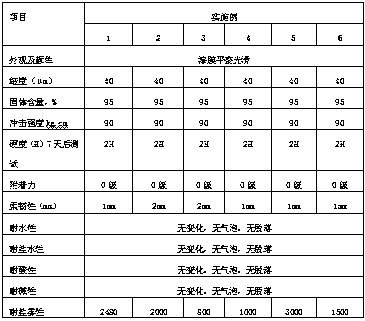

[0024] Weigh the resin, curing agent, powder and additives according to the formula quantity; first, graphene is ultrasonically dispersed, and then added according to the formula quantity: graphene is about 0.2%-5% of the total amount of materials, and the active diluent is the total amount of materials. The amount is 10-30%, the dispersant is 0.15-2% of the total material, the ultrasonic power is 100w-500w, and the time is 10min-60min; add the powder, resin and other materials into the graphene dispersion under mechanical stirring Among them, the stirring speed is 1000r / min, the epoxy resin is 5%-20% of the total material, the curing agent is 1.6%-6.6% of the total material, the zinc powder is 10%-50% of the total material, and the filler The amount of the additive is 10-40%, and the additive is 0.2%-1% of the total amount of the material; after the material is added, it is stirred with a 2000r / min mechanical mixer for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com