Method for extracting microalgae oil by adopting assistance of feeding digestive wall breaking of protozoon

A technology of protozoa and assisted extraction, which is applied in the direction of biofuel, fat production, fat oil/fat production, etc., can solve the problems of high cost and large water pollution, and achieve the effect of low pollution, low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

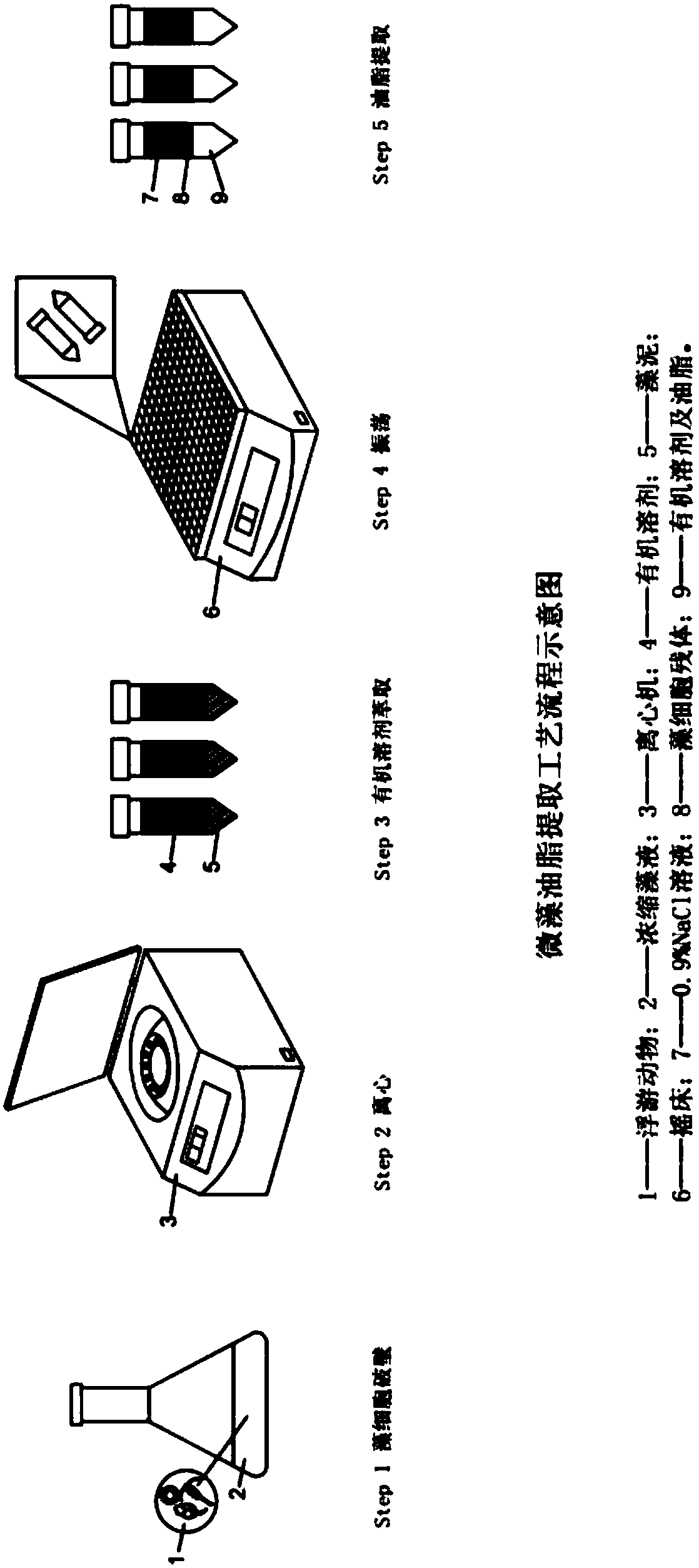

[0032] see figure 1 flow shown, to 1L the concentration is 1 x 10 8 3000 Daphnia were added to the chlorella algae liquid per mL, and the algae cells were broken through the feeding and digestion process of the Daphnia. The treatment time was 6 hours. / min centrifuge for 10min, use a 100-mesh filter to filter Daphnia, add 40mL of n-hexane / isopropanol with a volume ratio of 3:1 to the obtained algae mud, place it on a shaker for 3h, and add 10mL of 0.9% NaCl centrifugal layering, absorption of organic solvent and oil mixture, until the organic solvent is completely volatilized, after drying in a blast drying oven at 60°C, the crude oil can be obtained. The oil extraction rate can reach more than 98%, which is comparable to the traditional wall breaking method. Compared with that, the method provided by the invention has the advantages of high wall breaking efficiency and low cost.

Embodiment 2

[0034]see figure 1 flow shown, to 1L the concentration is 1 x 10 9 4000 brine shrimp were added to the Scenedesmus solution per mL, and the algae cells were broken through the feeding and digestion process of the brine shrimp. The treatment time was 12 hours. Centrifuge for 5 minutes, filter the brine shrimp with an 80-mesh filter, add 20 mL of n-hexane / isopropanol with a volume ratio of 2:1 to the obtained algae mud, place it on a shaker for 6 hours, and add 20 mL of 0.9% NaCl after the reaction is completed. Layering, absorption of organic solvent and oil mixture, after the organic solvent is completely volatilized, the crude oil can be obtained after drying in a blast drying oven at 80°C, and the oil extraction rate can reach more than 98%. Compared with the traditional wall breaking method, The method provided by the invention has the advantages of high wall breaking efficiency and low cost.

[0035] This scheme constructs a low-cost, high-efficiency, low-pollution techn...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap