House outer wall heat-insulating material pouring and decorating integrated construction system

A technology for thermal insulation materials and exterior walls, which is applied in thermal insulation, building structure, building components, etc., can solve the problems of high energy consumption due to glass light pollution, cumbersome and complicated construction procedures, and achieve omission of painting and leveling procedures, shortening the overall The effect of project duration and excellent thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further clarified below in conjunction with specific illustrations.

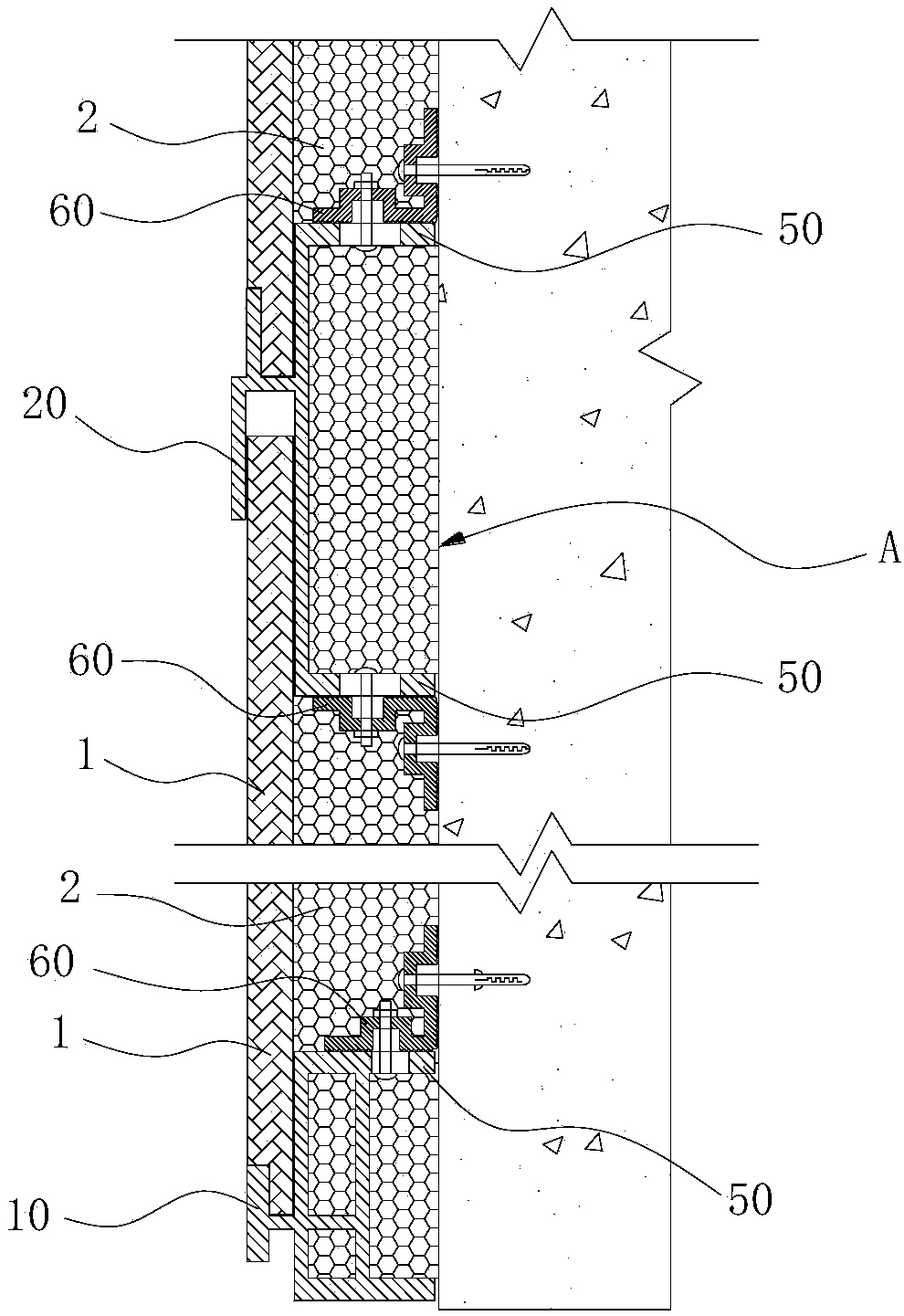

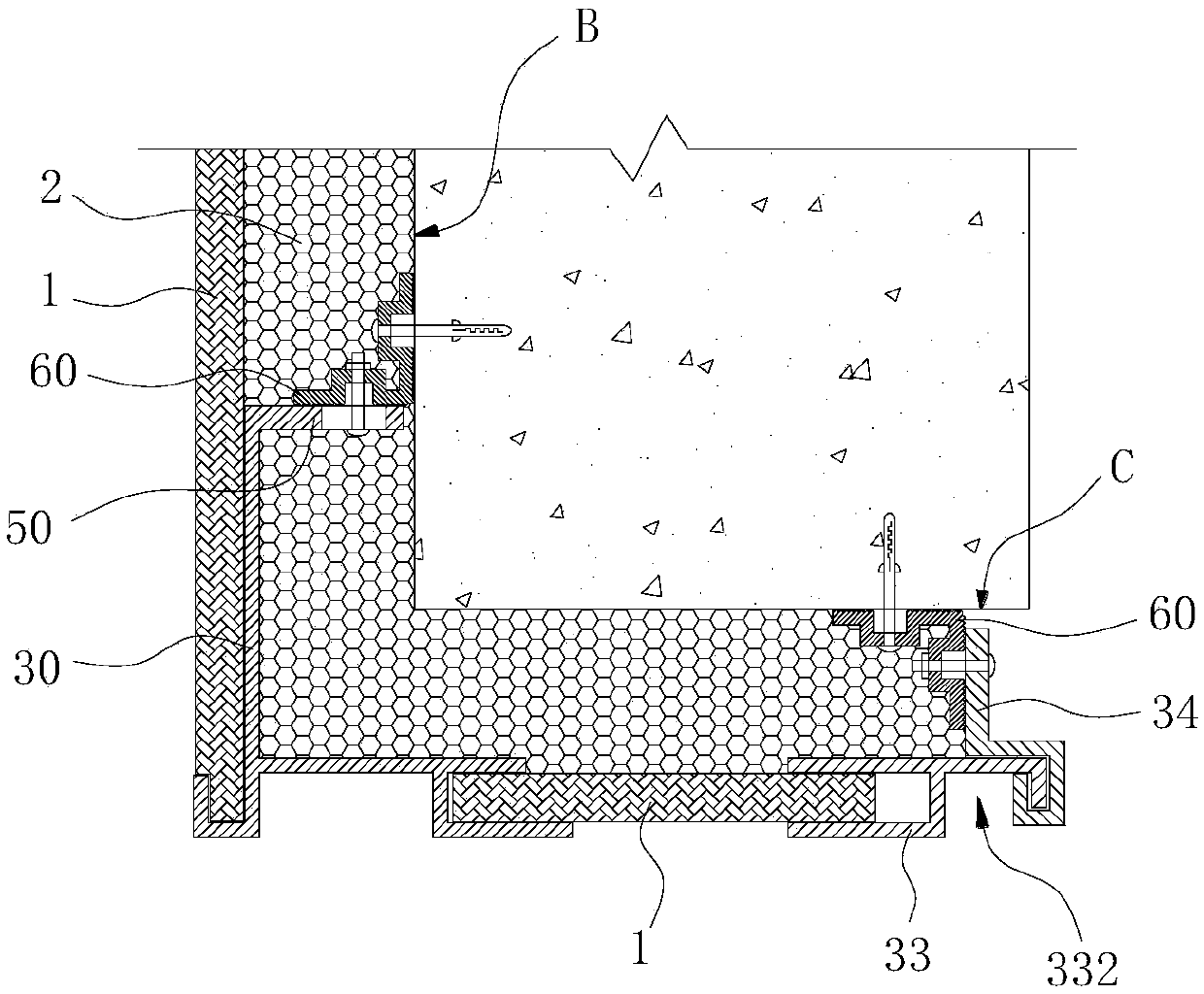

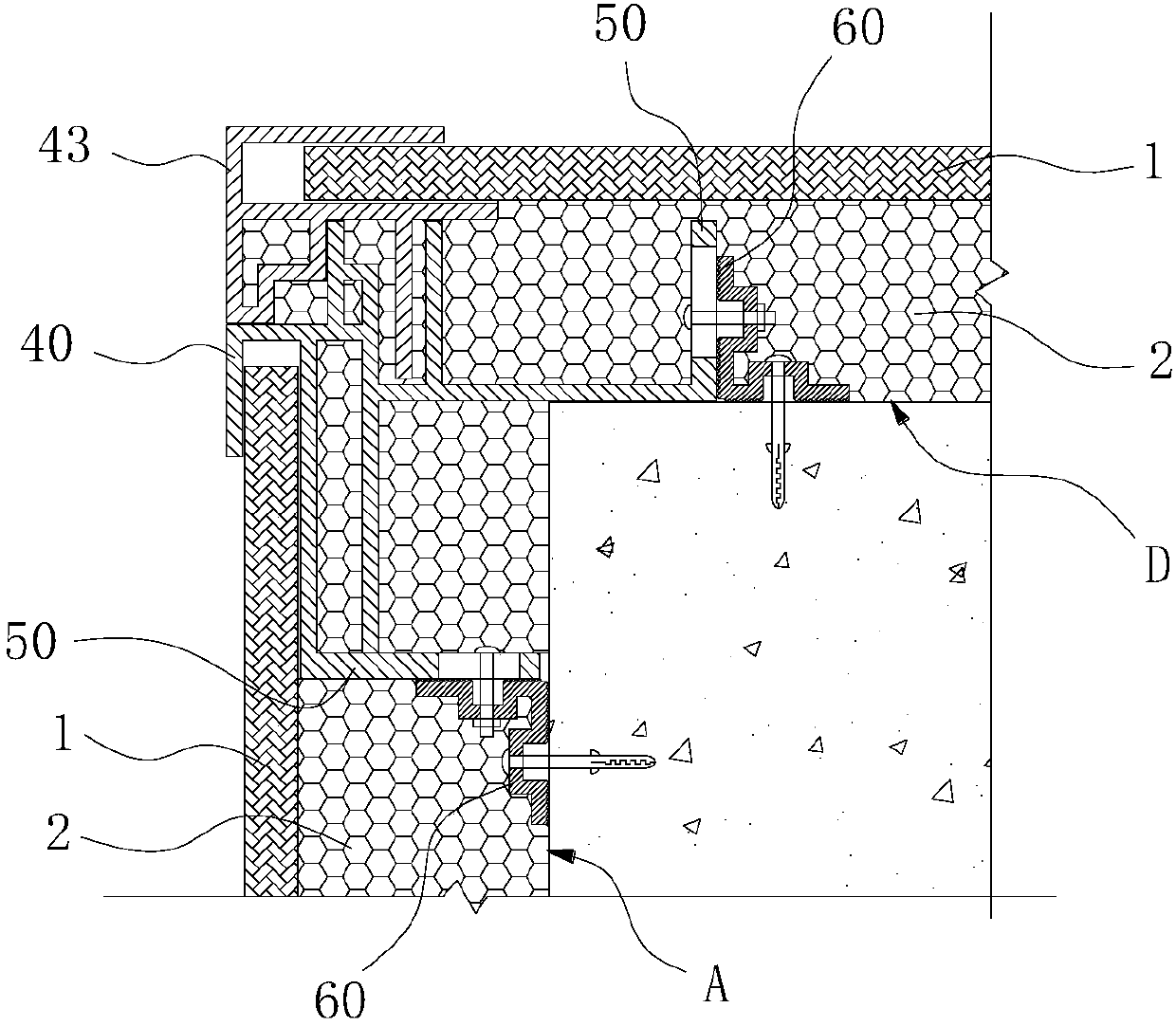

[0065] Such as Figure 1-8 As shown, the present invention provides an integrated construction system for pouring thermal insulation material decoration on the exterior wall of a house, including a fixed assembly fixedly connected to the wall to be decorated and heat-insulated. The fixed assembly is provided with an edge groove, adjacent A decorative board 1 is clamped in the edge receiving groove of the fixed assembly, and an insulating material 2 is poured into the cavity formed by the decorative board 1 and the wall surrounding the outside of the house.

[0066] In the present invention, the decorative panel 1 is fixedly installed through the fixing assembly arranged on the wall to be decorated and heat-insulated, and then the heat-insulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com