Multi-row synchronous rotating injection device for assisting sintering and injection method thereof

A technology of injection device and synchronous rotation, applied in the furnace type, furnace, electrical components, etc., can solve the problems of raw material and energy waste, safety accidents, uneven sintering degree, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0101] According to a fourth embodiment of the present invention, there is provided a method for blowing gas using the above-mentioned blowing device 1 of the claim, comprising:

[0102] 1. Gas is fed in, and the driving device M drives the blocking pipe 61 to rotate synchronously;

[0103] 2. The gas flow rate in the gas branch pipe 4 is detected by the gas detection module, and the real-time speed of the matching plugging body 61 is judged by the speed control module according to the detected flow value, and the speed is converted into the output power of the motor, thereby changing The rotational speed of blocking pipe body 61;

[0104] 3. The sequential forward and reverse output control device presets the time point. When the time detection module detects that the running time of the driving motor reaches the preset time point, the motor control module can control the working state of the motor drive module at the preset time point. That is, forward rotation or reverse r...

Embodiment 1

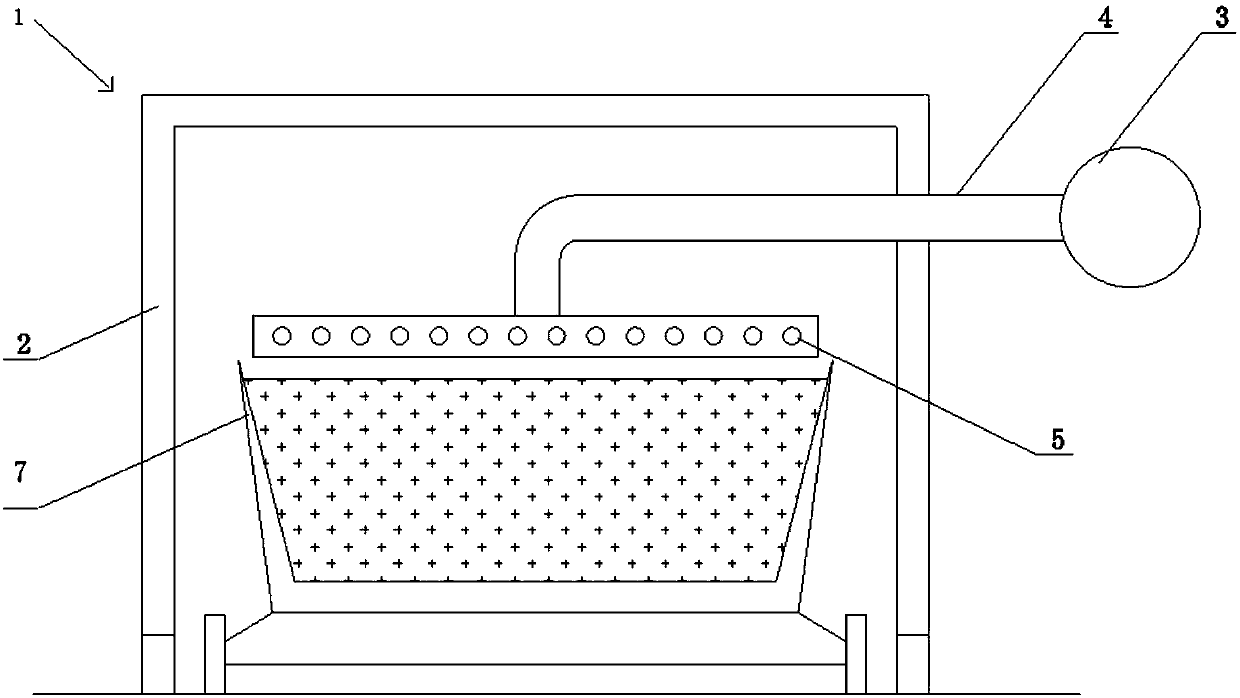

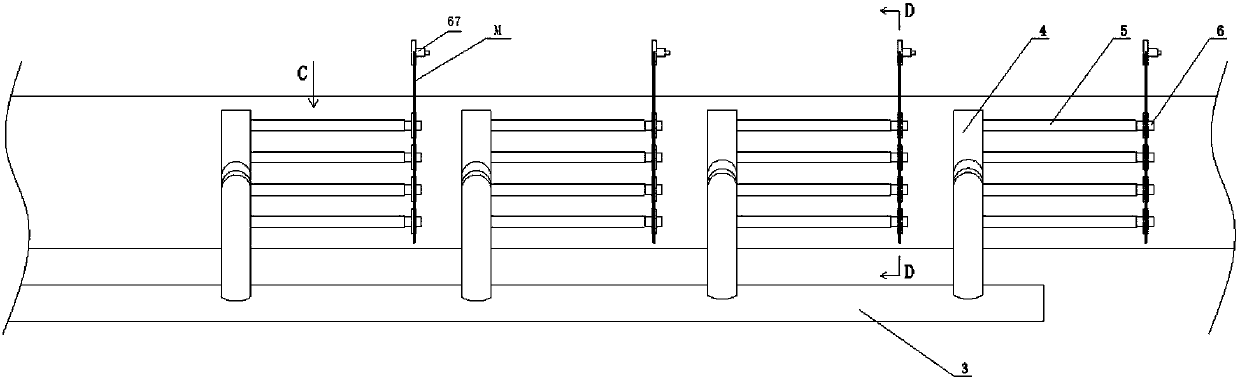

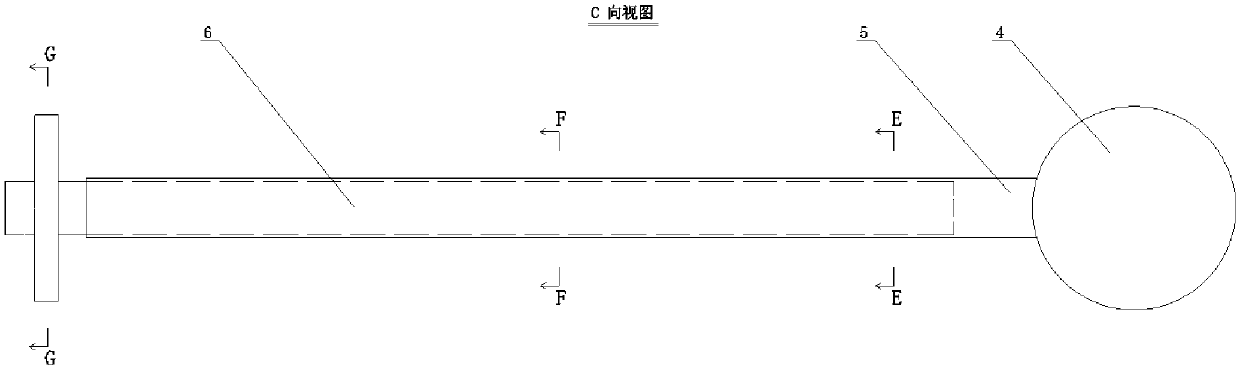

[0108] A multi-row synchronous rotary blowing device 1 for auxiliary sintering, comprising: a sintering trolley 7, an injection sealing cover 2 is arranged above the sintering trolley 7, and 20 A gas blowpipe 5, and 5 gas branch pipes 4, each gas branch pipe 4 is connected with 4 gas blowpipes 5, a gas main pipe 3 is arranged outside the injection sealing device 2, and the gas branch pipe 4 is connected through the injection sealing device 2 The gas main pipe 3 and the gas blowpipe 5, the gas blowpipe 5 comprises the blow pipe 51 and the blow hole 52 of the blow pipe, and the blow pipe 51 offers 1 group of blow holes 52 of the blow pipe along the circumferential direction, and the axial direction of the blow pipe 51 is distributed successively 10 Group blowing pipe blowing hole 52, described one group of blowing pipe blowing hole 52 is 11, and the inner coaxial line of blowing pipe 51 is provided with blocking pipe body 61, and blocking pipe body 61 one end exposes gas blowing ...

Embodiment 2

[0112] A multi-row synchronous rotary blowing device 1 for auxiliary sintering, comprising: a sintering trolley 7, an injection sealing cover 2 is arranged above the sintering trolley 7, and a 60 A gas blowpipe 5, and 10 gas branch pipes 4, each gas branch pipe 4 is connected with 6 gas blowpipes 5, a gas main pipe 3 is arranged outside the injection sealing device 2, and the gas branch pipe 4 is connected through the injection sealing device 2 The gas main pipe 3 and the gas blowpipe 5, the gas blowpipe 5 comprises the blow pipe 51 and the blow hole 52 of the blow pipe, and the blow pipe 51 offers 1 group of blow holes 52 of the blow pipe along the circumferential direction, and the axial direction of the blow pipe 51 is distributed successively 10 Group blowing pipe blowing hole 52, described one group of blowing pipe blowing hole 52 is 11, and the inner coaxial line of blowing pipe 51 is provided with blocking pipe body 61, and blocking pipe body 61 one end exposes gas blowi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com