Method of processing waste resin of nuclear power plant

A treatment method and waste resin technology, applied in sampling devices, dosimeters, etc., can solve the problems of high treatment cost, high cost of curing agent, low containment capacity, etc., and achieve the goal of reducing treatment cost, reducing safety hazards, and reducing treatment cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

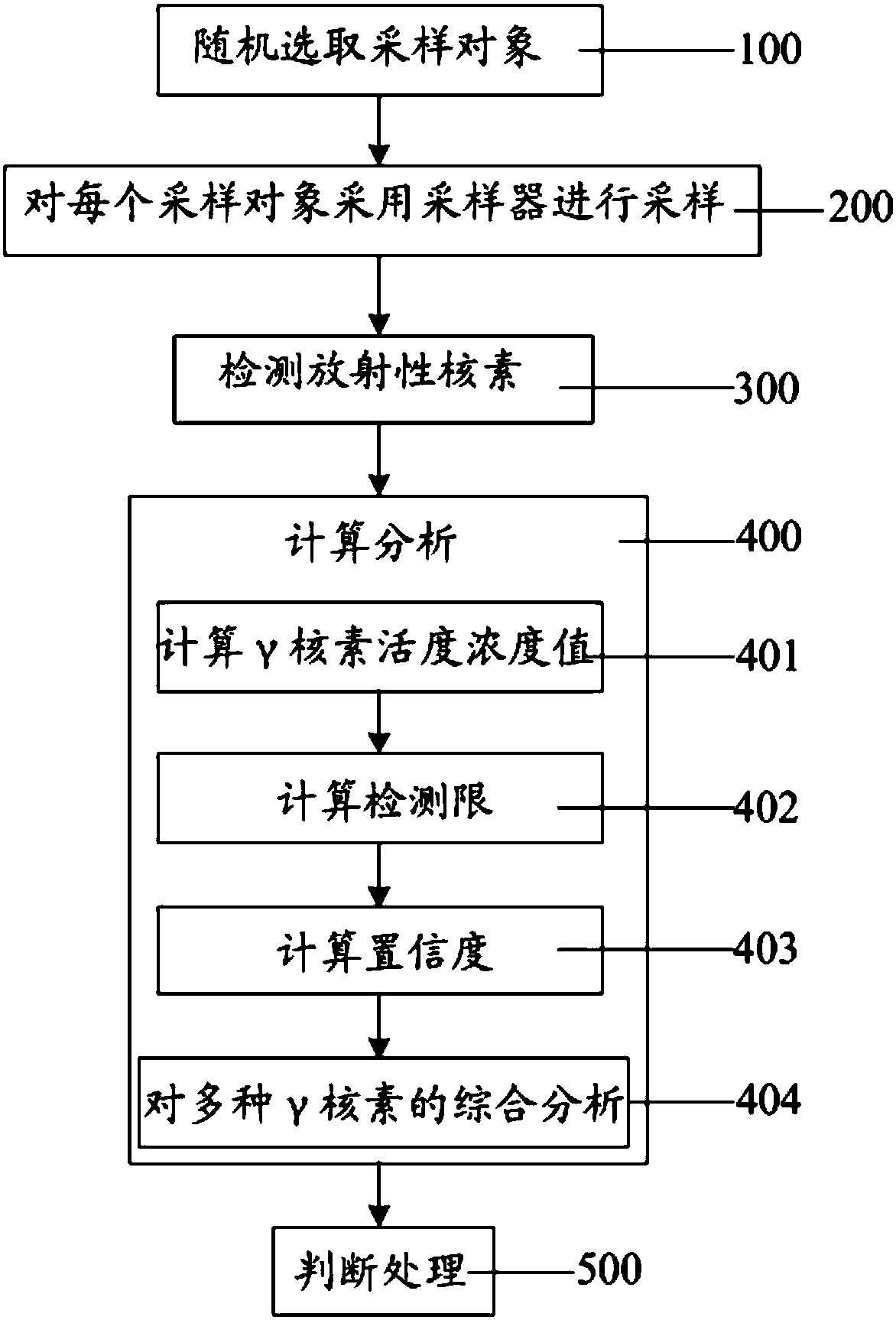

[0032] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

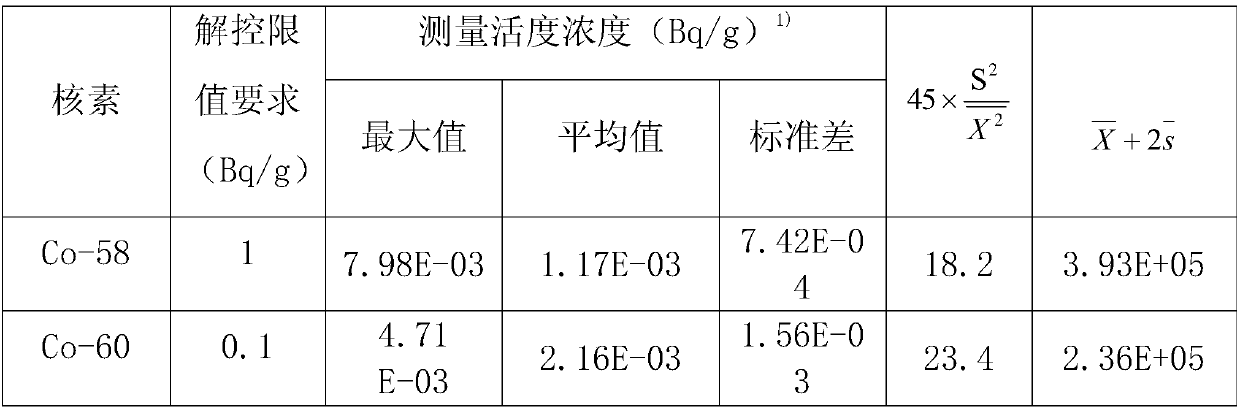

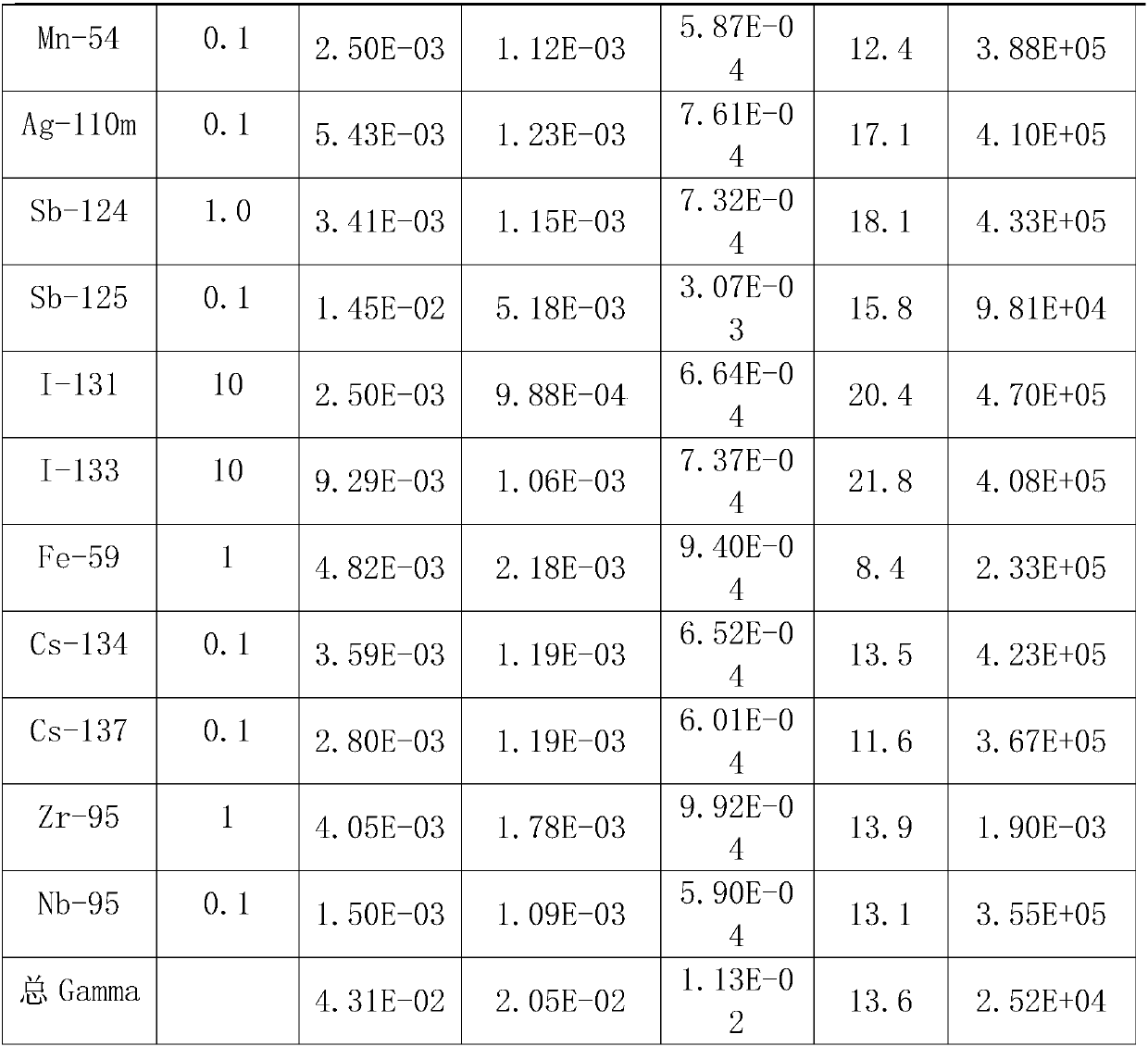

[0033] The current APG waste resin treatment method usually adopts full curing treatment, but considering that when replacing APG resin, radiation protection personnel usually perform surface dose on the discharge pipeline, monitoring window and APG waste resin flushed into the mobile resin storage tank Rate measurement, and take samples of the resin discharged into the storage tank for chemical analysis. If there is no abnormal leakage caused by the breakage of the U-shaped tube barrier of the steam generator, the probability of APG waste resin being radioactively contaminated is extremely small, so the processing Before APG waste resin, the γ nuclide activity concentration value in APG waste resin can be detected first to judge whether it exceeds the cleaning clearance level stipulated by the state. If it exceeds the standard for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com