Arc extinguish chamber of molded case circuit breaker

A technology for molded case circuit breakers and arc extinguishing chambers, which is applied to circuit breaker parts, circuits, electrical components, etc., to achieve the effects of improving arc extinguishing performance, increasing arc extinguishing magnetic field, and promoting deionization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

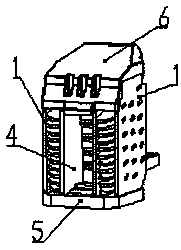

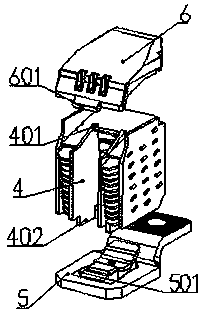

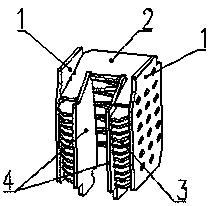

[0019] Such as figure 1 , 2 As shown in , 3, the upper part of the arc extinguishing chamber is a cover plate 6, and in the middle are several U-shaped metal grids 3 stacked horizontally with intervals up and down, and the static contacts 5 are directly below the metal grids 3. Right above the metal grid 3 is a U-shaped arc starter 2 , which is below the cover plate 6 and has a gap with the metal grid 3 . On the left and right sides of the U shape of the metal grid 3 and the arc striker 2, there is a vertical arc barrier 1, the metal grid 3 and the arc striker 2 are located between the two arc barriers 1, and the metal The left and right side walls of the grid piece 3 and the arc-starting piece 2 are fixedly clamped on two arc-breaking walls 1, and the metal grid piece 3 and the arc-leading piece 2 are fixed by the two arc-breaking walls 1.

[0020] On the inside of the U-shaped opening of the metal grid sheet 3 and the arc-starting sheet 2, a prefabricated sheet-shaped gas-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com