Electrolyte solution and preparation method for improving performance of solid electrolyte membrane on graphite electrode surface

A solid electrolyte membrane, graphite electrode technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of increasing the self-discharge rate of the battery, reducing the first efficiency of the battery, affecting the cycle efficiency of the battery, etc., to reduce internal resistance, improve Capacity retention, effect of improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

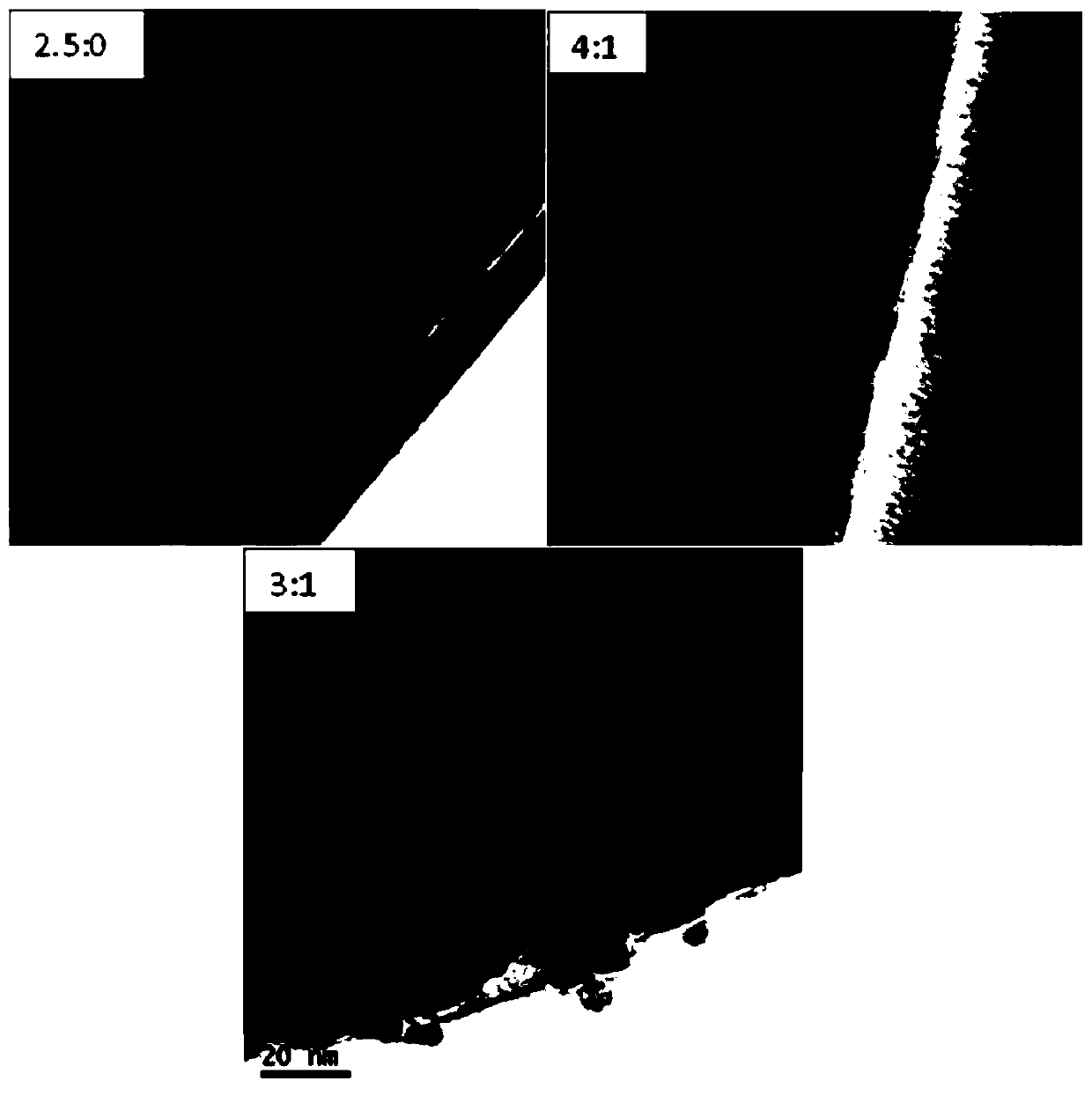

Embodiment 1

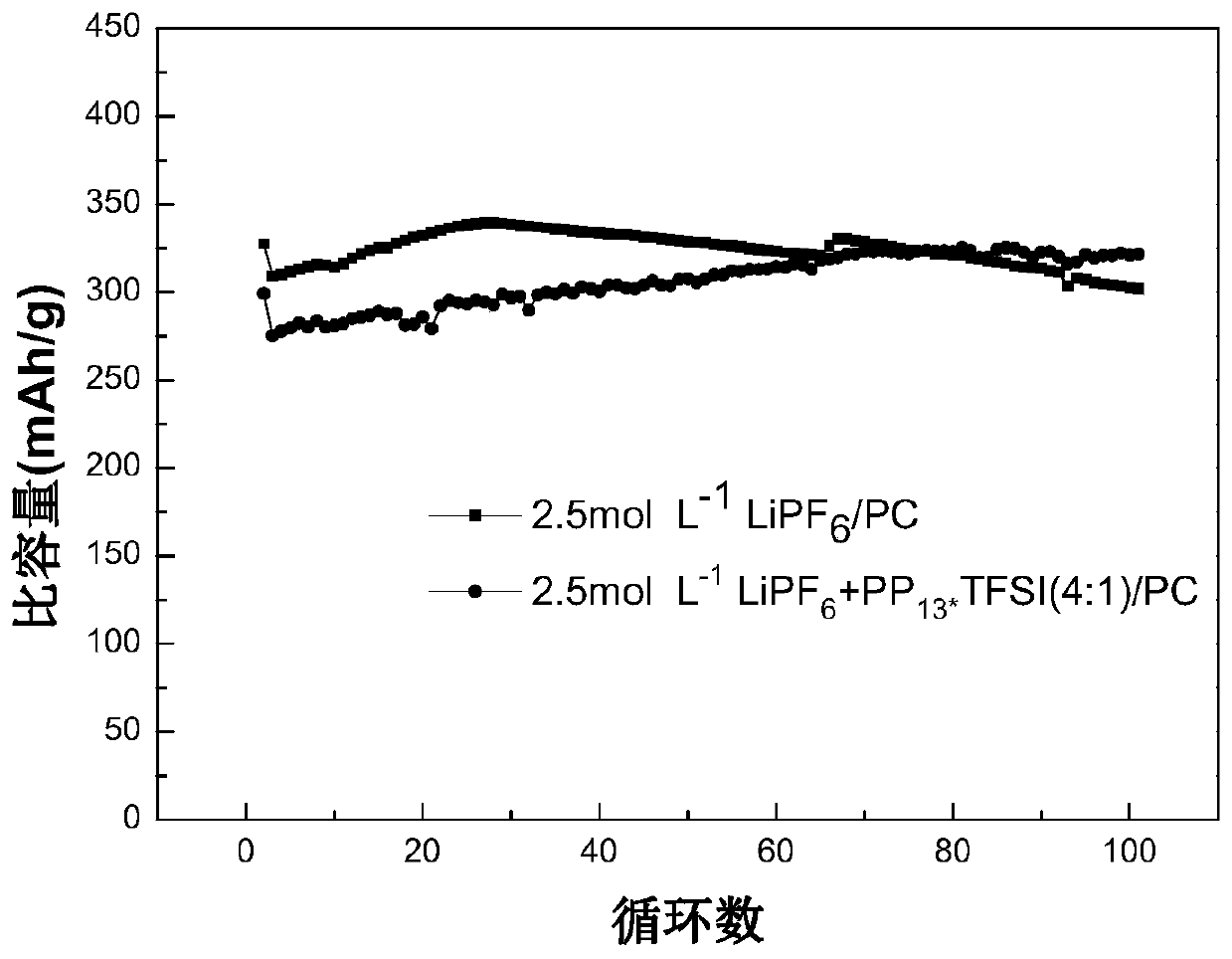

[0030] The electrolytic solution in the present invention is prepared in a glove box, and the main components are: an organic solvent and a lithium salt. Described organic solvent is propylene carbonate (PC), and lithium salt is LiPF 6 , the molar concentration of lithium salt in the organic solvent is 2.5mol / L.

[0031] The preparation method of above-mentioned lithium ion battery electrolyte:

[0032] Weigh the stoichiometric LiPF according to the molar concentration of the electrolyte 6 , dissolved in a certain volume of PC solvent, shake well, and let stand for at least 24 hours.

[0033] The lithium-ion battery electrolyte obtained in this example was used to assemble a graphite-lithium button half-cell, and the charge-discharge cycle performance of the graphite-lithium half-cell was tested at room temperature at a rate of 0.01-2V and 0.1C. The capacity retention after 100 cycles was 92%.

Embodiment 2

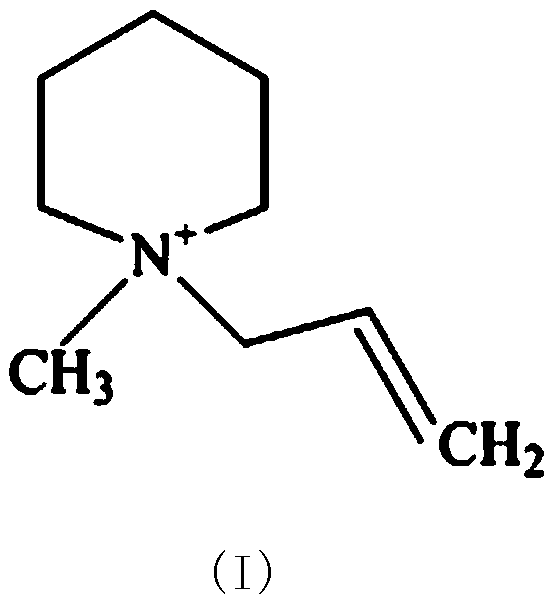

[0035] The electrolytic solution in the present invention is prepared in a glove box, and the main components are: organic solvent, lithium salt, and ionic liquid. Described organic solvent is propylene carbonate (PC), and lithium salt is LiPF 6 , the ionic liquid is PP 13 *TFSI, LiPF 6 and PP 13 *The molar ratio of TFSI is 4:1, and the total molar concentration of lithium salt and ionic liquid in the organic solvent is 2.5mol / L.

[0036] The preparation method of above-mentioned lithium ion battery electrolyte:

[0037] Step 1, weigh the stoichiometric PP according to the molar concentration of the electrolyte and the molar ratio of the lithium salt to the ionic liquid 13 *TFSI, dissolved in a certain volume of PC solvent;

[0038] Step 2, weigh the stoichiometric LiPF according to the molar concentration of the electrolyte and the molar ratio of lithium salt and ionic liquid 6 , dissolved in the mixed solution of 1);

[0039] Step 3, shake the above solution well and ...

Embodiment 3

[0042] The electrolytic solution in the present invention is prepared in a glove box, and the main components are: organic solvent, lithium salt, and ionic liquid. Described organic solvent is propylene carbonate (PC), and lithium salt is LiPF 6 , the ionic liquid is PP 13 *TFSI, LiPF 6 and PP 13 *The molar ratio of TFSI is 3:1, and the total molar concentration of lithium salt and ionic liquid in the organic solvent is 2.5mol / L.

[0043] The preparation method of above-mentioned lithium ion battery electrolyte:

[0044] Step 1, weigh the stoichiometric PP according to the molar concentration of the electrolyte and the molar ratio of the lithium salt to the ionic liquid 13 *TFSI, dissolved in a certain volume of PC solvent;

[0045] Step 2, weigh the stoichiometric LiPF according to the molar concentration of the electrolyte and the molar ratio of lithium salt and ionic liquid 6 , dissolved in the mixed solution of 1);

[0046] Step 3, shake the above solution well and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com