Sound wave agglomeration dust removal system

A dust removal system and sound wave technology, applied in the field of pollution control equipment manufacturing, can solve the problems of weak PM2.5 small particle dust adsorption, high PM2.5 dust particle content, and low removal efficiency, so as to reduce the dust particle content , to ensure stability and reduce the effect of air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

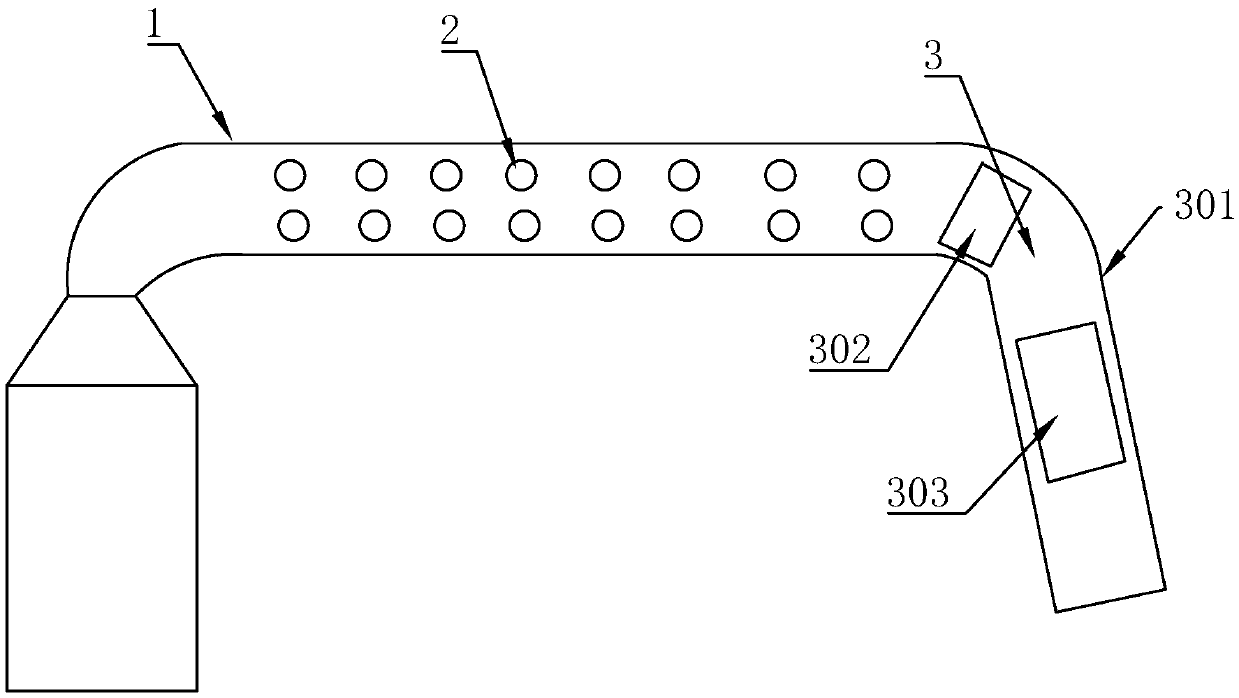

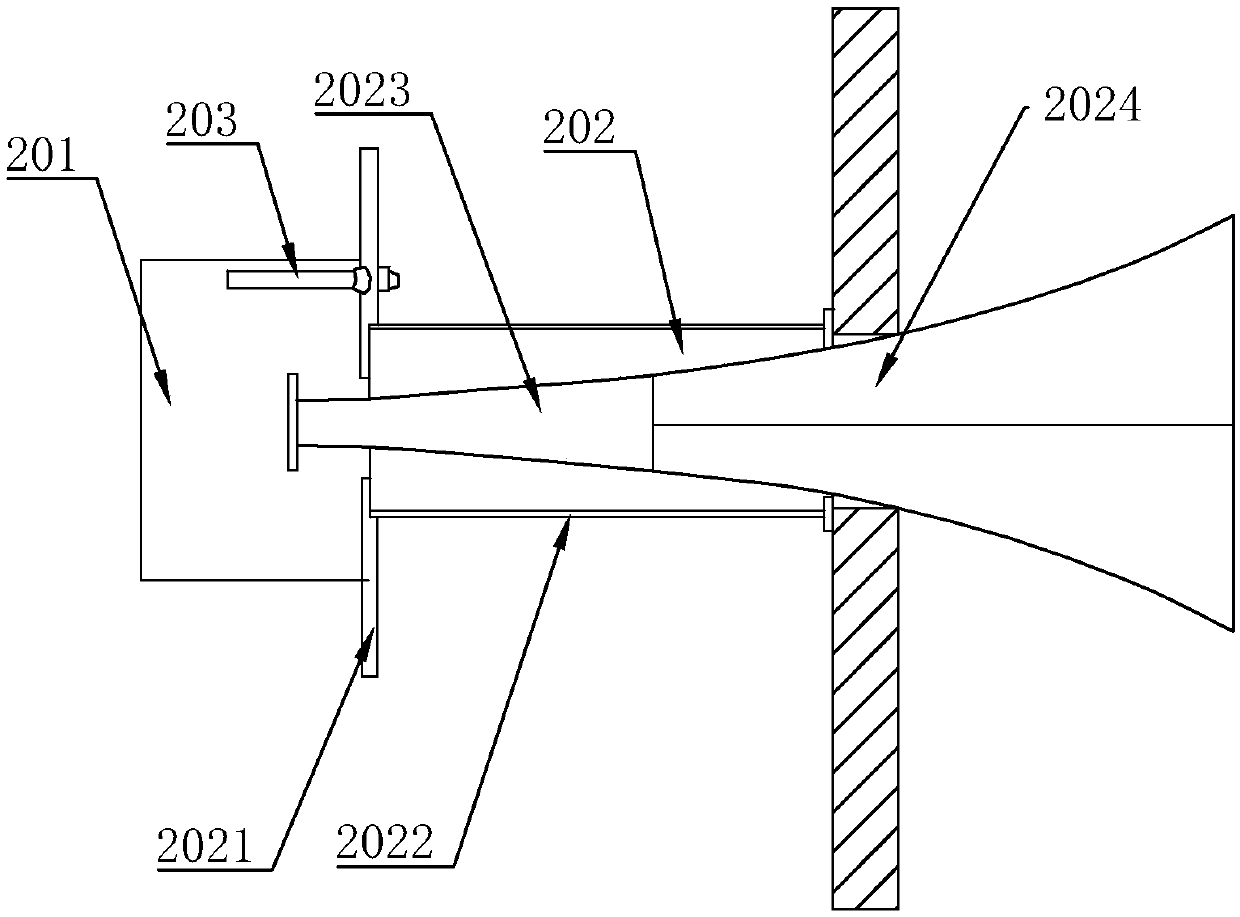

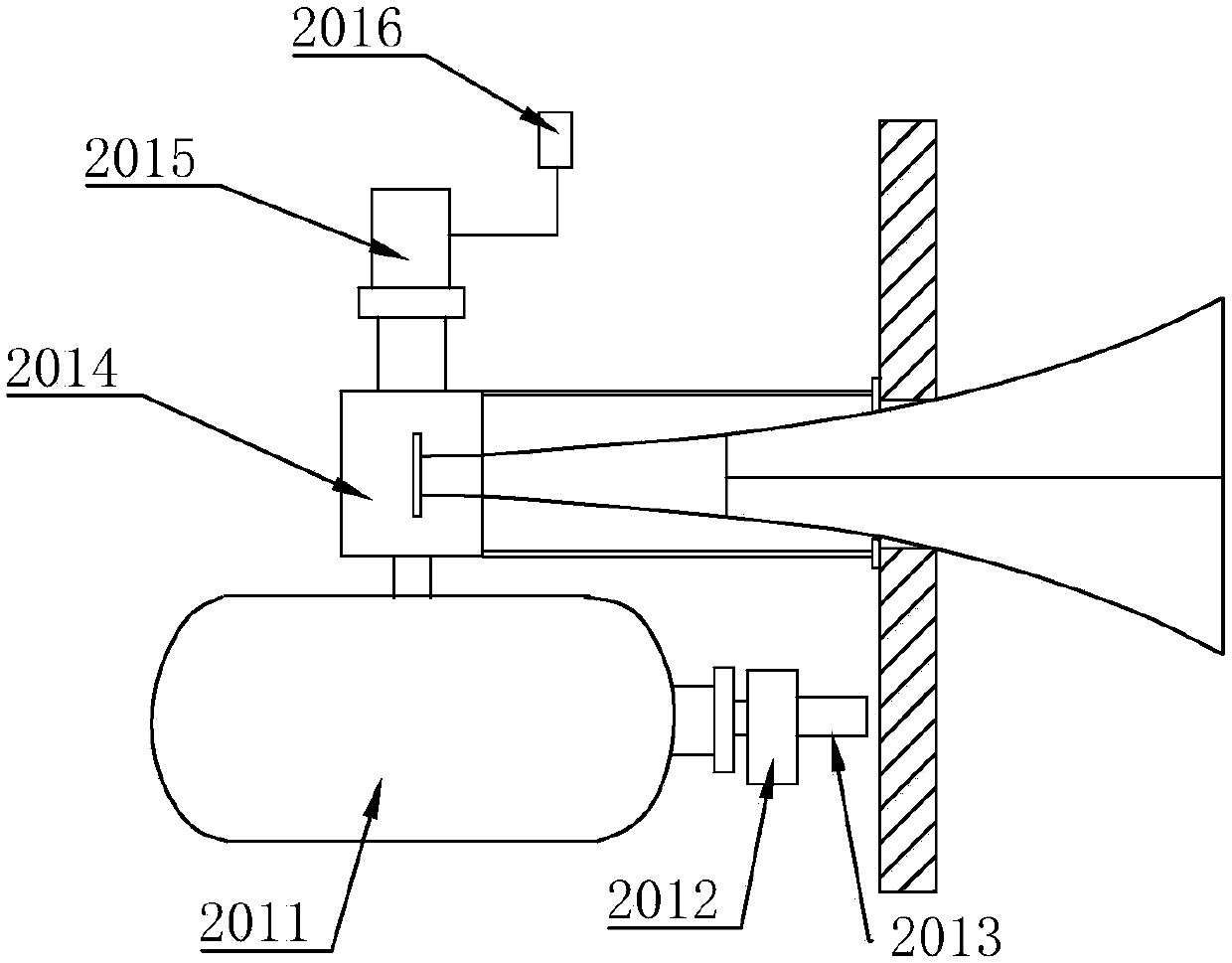

[0026] Such as figure 1 As shown, a sonic agglomeration and dedusting system of the present invention includes a sonic ash remover 2 and a mist eliminator 3. The sonic ash remover 2 is provided with multiple and symmetrically arranged on both sides of the flue gas channel 1 of the desulfurization tower, and the mist eliminator 3 are arranged in a matrix and connected to the smoke outlet of the flue gas channel 1 of the desulfurization tower.

[0027] Small particles of soot are discharged into the flue gas channel through the desulfurization tower. First, the sonic soot remover 2 sends out high sound pressure and low frequency sound waves in the flue gas channel, causing large vibrations of small particles of soot in the flue gas channel, making the small particles of soot Due to the high humidity of the flue gas, small particles of smoke and dust will have an agglomeration effect during the process of mutual friction and collision. Under this effect, small particles of smoke ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com