An insulated pure electric passenger car fuel cell box with temperature regulation performance

A pure electric bus and fuel cell technology, applied in the field of bus, can solve the problems of affecting the normal operation of the battery, generating a large amount of heat from the battery, and affecting the work of the battery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

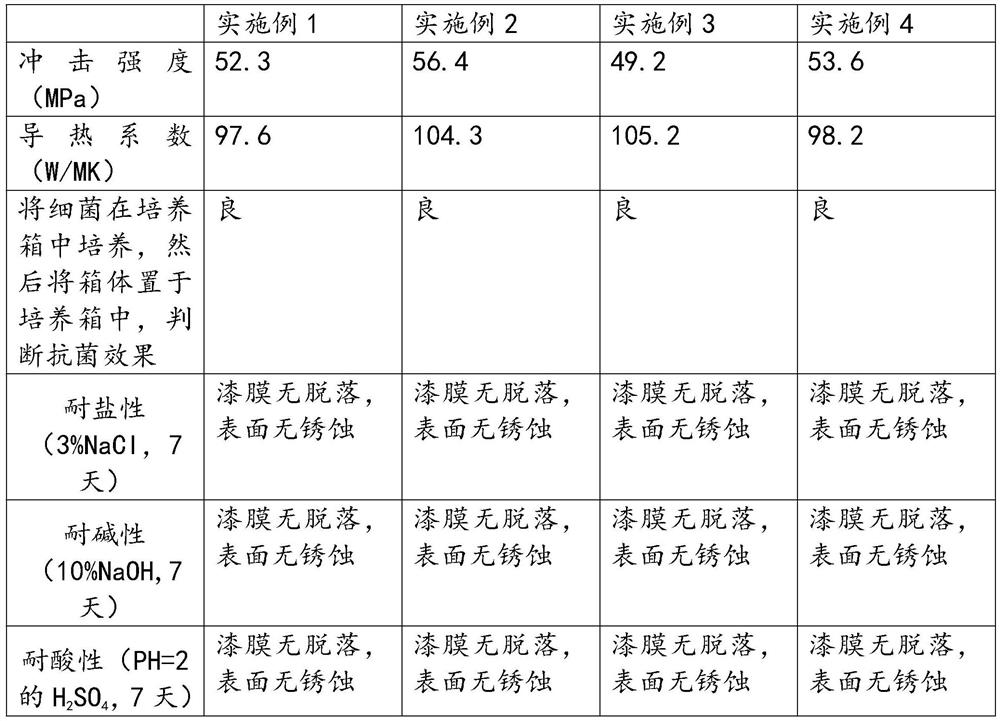

Examples

Embodiment 1

[0022] An insulated pure electric passenger car fuel cell box with temperature regulation performance, including a box body, which is made of silicon carbide composite material;

[0023] The preparation process of the box body is as follows:

[0024] (1) Mix silicon carbide and dextrin according to a certain ratio. The amount of dextrin is 30% of the mass of silicon carbide. Then add ethanol solvent to grind. After the grinding is uniform, it is dried in an oven at 40 ℃, and then at 1400 ℃. Sintering at a temperature of, to obtain macroporous silicon carbide;

[0025] (2) Take the silicon powder and the macroporous silicon carbide prepared in step 1 and put them in a high-speed mixer at a mass ratio of 1:5.3, and then add water, a binding agent and an anti-precipitation agent to the mixer. The binding agent is a phenolic resin. The ratio of the added amount of the agent to the added amount of silicon powder is 1:2.3, high-speed stirring for 2 hours to obtain the mixture, then the mi...

Embodiment 2

[0032] An insulated pure electric passenger car fuel cell box with temperature regulation performance, including a box body, which is made of silicon carbide composite material;

[0033] The preparation process of the box body is as follows:

[0034] (1) Mix silicon carbide and dextrin according to a certain ratio. The amount of dextrin accounts for 36% of the silicon carbide mass. Then add ethanol solvent to grind. After the grinding is uniform, it is dried in an oven at 47 ℃, and then dried at 1400 ℃. Sintering at a temperature of, to obtain macroporous silicon carbide;

[0035] (2) Take the silicon powder and the macroporous silicon carbide prepared in step 1 and put them in a high-speed mixer at a mass ratio of 1:7.4, and then add water, a binding agent and an anti-precipitation agent to the mixer. The binding agent is a phenolic resin. The ratio of the added amount of the agent to the added amount of silicon powder is 1:2.8. Stir at high speed for 3 hours to obtain the mixture,...

Embodiment 3

[0042] An insulated pure electric passenger car fuel cell box with temperature regulation performance, including a box body, which is made of silicon carbide composite material;

[0043] The preparation process of the box body is as follows:

[0044] (1) Mix silicon carbide and dextrin according to a certain ratio. The amount of dextrin accounts for 38% of the silicon carbide mass. Then add ethanol solvent to grind. After the grinding is uniform, it is dried in an oven at 60°C, and then dried at 1400°C. Sintering at a temperature of, to obtain macroporous silicon carbide;

[0045] (2) Take the silicon powder and the macroporous silicon carbide prepared in step 1 and place them in a high-speed mixer at a mass ratio of 1:7.9, and then add water, a binding agent and an anti-precipitation agent to the mixer. The binding agent is a phenolic resin. The ratio of the added amount of the agent to the added amount of silicon powder is 1:2.5. Stir at a high speed for 4 hours to obtain the mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com