Fluorescent electronic protective paint and preparation method thereof

A protective coating, fluorescent technology, applied in luminescent coatings and other directions, can solve the problems of performance degradation, long preparation time, and difficult coating, and achieve strong adaptability and durability, stable fluorescence visibility, good environmental friendliness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

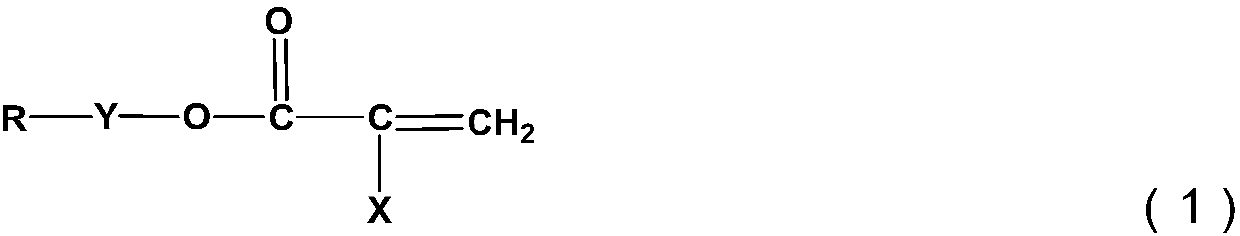

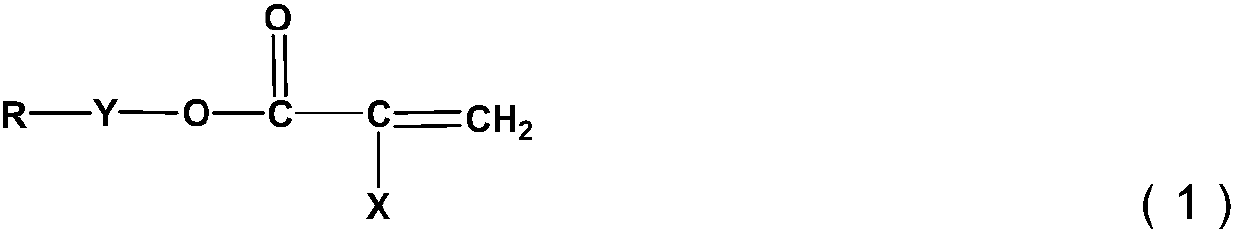

Method used

Image

Examples

example 1

[0036] (1) 0.2g CTAB (a kind of quaternary ammonium salt surfactant that is a cationic emulsifier), 0.2g AE09 (a kind of fatty alcohol polyoxyethylene ether that is a co-emulsifier) are mixed with 40g water, Stir at 10°C for 30 min to obtain an emulsifier solution.

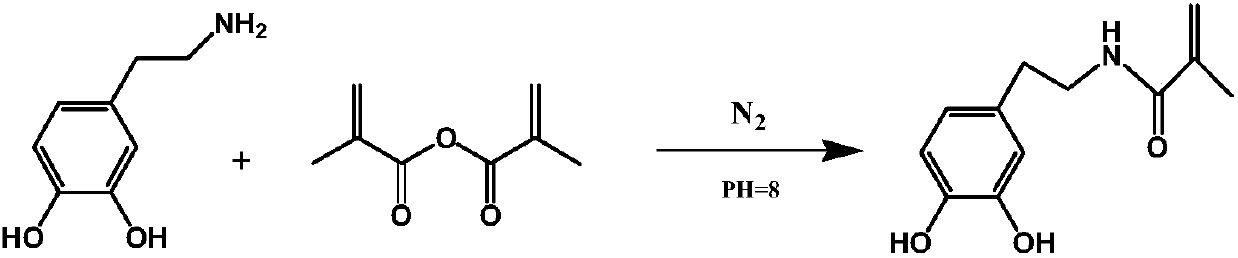

[0037] (2) 4g perfluorohexaneethyl methacrylate (C6MA), 5g octadecyl acrylate, 0.01g dopamine methacrylamide, 0.001g 1,8-naphthalimide acrylate and step (1) to obtain The emulsifier solution was mixed, vigorously stirred for 30 minutes, and then treated with an ultrasonic cell pulverizer for 5 minutes to obtain a monomer pre-emulsion.

[0038] (3) Pour the monomer pre-emulsion into a container, heat to 60° C., add 0.1 g of azobisisoheptanonitrile, and polymerize at constant temperature for 6 hours. The reacted emulsion is demulsified with ethanol, and the resulting precipitate is filtered and dissolved with perfluoro-2-n-butyltetrahydrofuran, and the fluoropolymer is precipitated with a large amount of methanol...

example 2

[0040] (1) Mix 0.1g CTAB, 0.1g AE09 and 36g water, and stir at 15°C for 25min to obtain an emulsifier solution.

[0041] (2) Add 6g of (N-methylperfluorohexanesulfonamido)ethyl acrylate (C6SA), 3g of cetyl methacrylate, 0.1g of dopamine methacrylamide, 0.01g of 1,8-naphthalene Amine acrylate, 0.1 g of dodecanethiol and the emulsifier solution obtained in step (1) were mixed, vigorously stirred for 20 minutes, and then treated with an ultrasonic cell pulverizer for 8 minutes to obtain a monomer pre-emulsion.

[0042] (3) Pour the monomer pre-emulsion into a container, heat to 70° C., add 0.15 g of azobisisoheptanonitrile, and polymerize at constant temperature for 5 hours. The reacted emulsion is demulsified with ethanol, the obtained precipitate is filtered, and perfluoro-2-n-butyltetrahydrofuran is dissolved, and a large amount of methanol is used to precipitate the fluorine-containing polymer, repeated several times, and heated and dried to obtain a pure polymer. Finally, t...

example 3

[0044] (1) Mix 0.05g CTAB, 0.05g AE09 and 32g water, and stir at 20°C for 20min to obtain an emulsifier solution.

[0045] (2) Add 9g of (N-methylperfluorohexanesulfonamido) ethyl methacrylate (C6SMA), 0.1g of norbornyl acrylate, 0.2g of dopamine methacrylamide, 0.3g of 1,8-naphthalene Imide acrylate, 0.2 g of dodecanethiol and the emulsifier solution obtained in step (1) were mixed, vigorously stirred for 10 min, and then treated with an ultrasonic cell pulverizer for 10 min to obtain a monomer pre-emulsion.

[0046] (3) Pour the monomer pre-emulsion into a container, heat to 80° C., add 0.2 g of azobisisoheptanonitrile, and polymerize at constant temperature for 3 hours. The reacted emulsion is demulsified with ethanol, the resulting precipitate is filtered and dissolved with HFE-458, and a large amount of methanol is used to precipitate the fluoropolymer, repeated several times, heated and dried to obtain a pure polymer. Finally, the formulated coating composition was diss...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com