A kind of preparation method for the fluorescent film structure of LED

A thin-film structure and fluorescence technology, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of shortening the packaging process, fluorescent powder precipitation, and reducing production costs, so as to achieve reduced packaging process, convenient size, and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

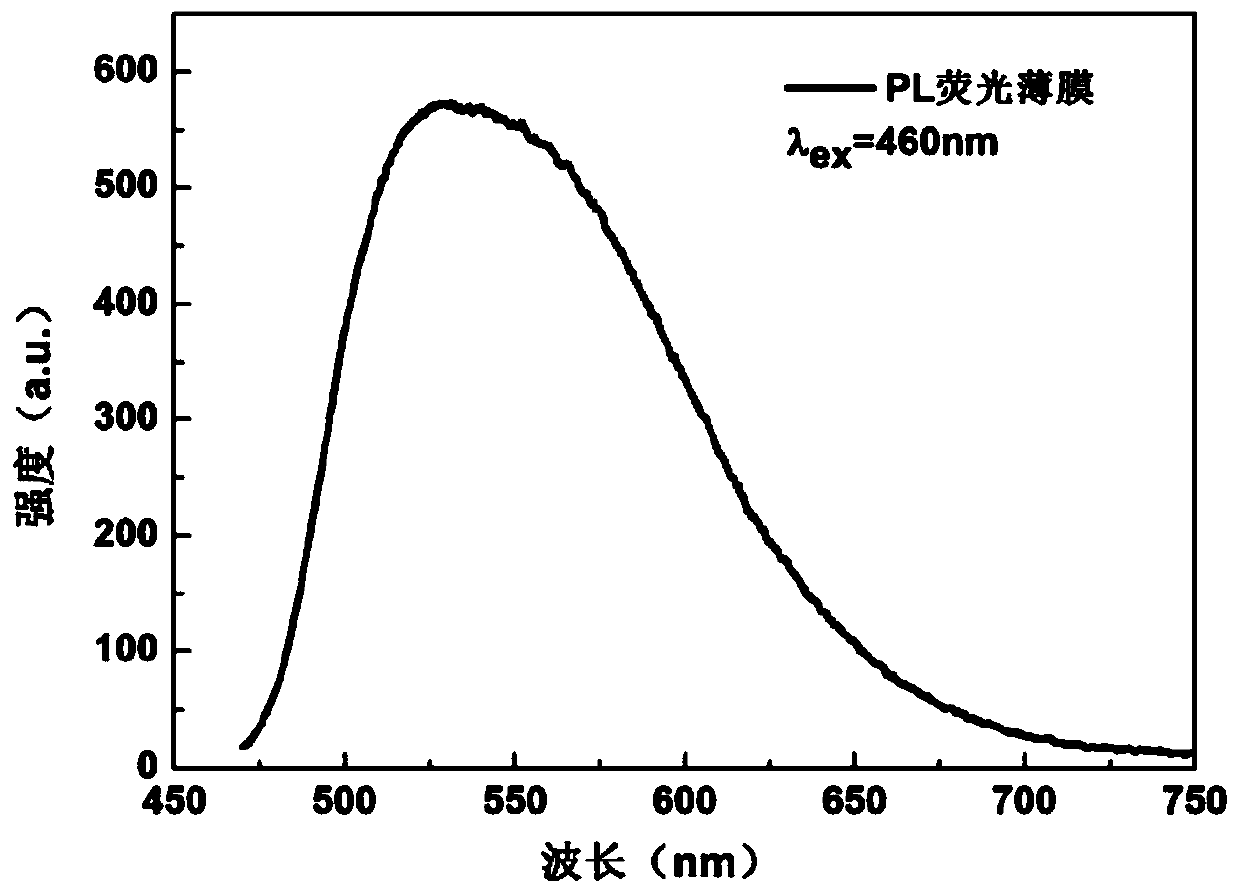

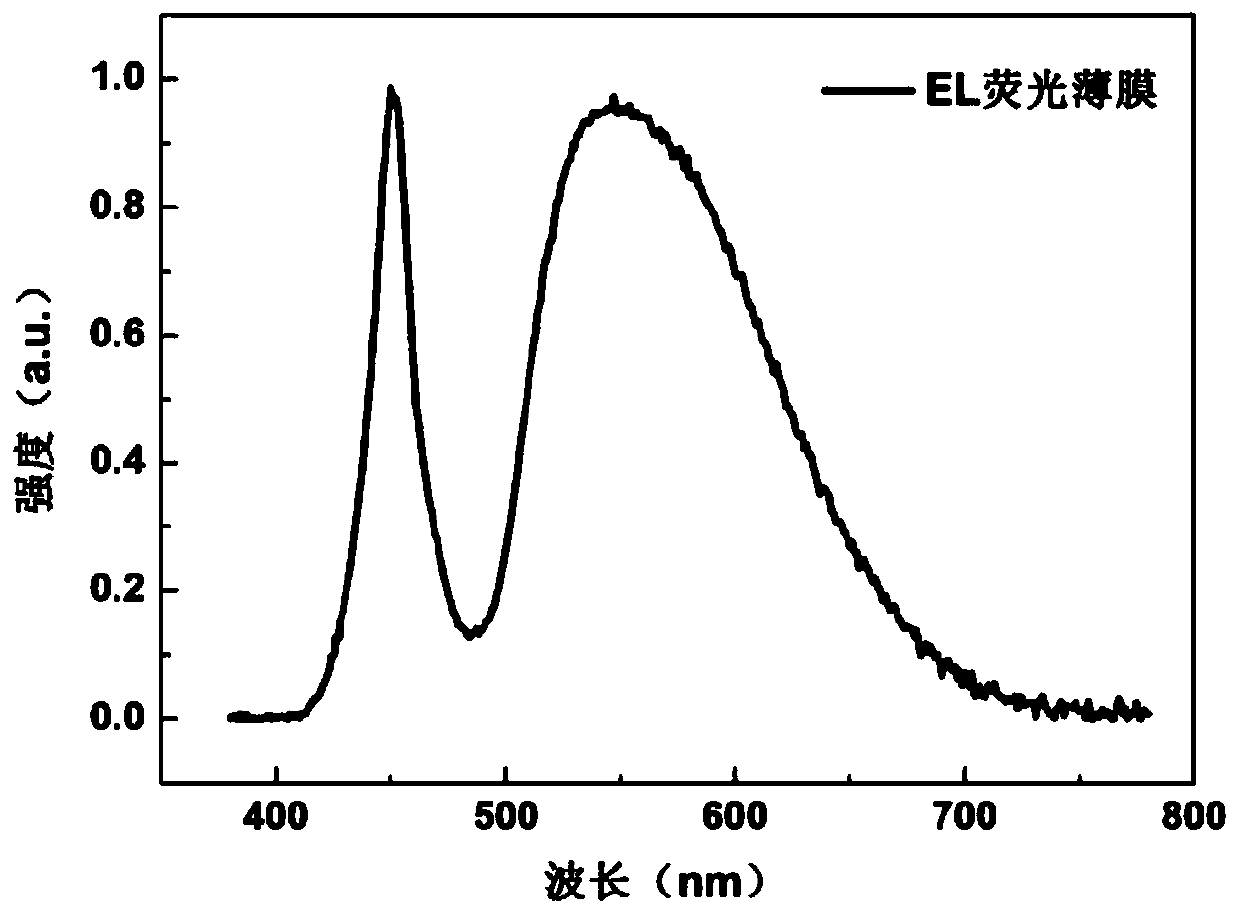

[0037] Weigh A, B silica gel, YAG (Y 3 al 5 o 12 : Ce) Phosphor powder 5g, 5g, 1.5g, that is, the proportion is A:B:YAG=1:1:0.3, it is fully mixed evenly, after the mixed fluorescent glue is degassed and vacuumized, it is placed in the feed The cylinder is spin-coated on the PET film placed on the glass substrate. The acceleration of the first stage of the homogenizer is: 340rpm / s, the speed of the second stage of the uniform stage is: 420rpm / s, and the third stage is the stop stage. Both acceleration and acceleration are 0rpm / s, and the spin coating time is 160s. Afterwards, it was cured in an oven at 80°C for 20 minutes, and then cured at 150°C for 10 minutes. On the basis of the first layer, spin coat another layer according to the above-mentioned ratio and method. The third layer is the boron nitride layer. Before coating, the boron nitride is ultrasonically oscillated for 30 minutes. The boron nitride is dispersed in isopropanol with a concentration of 2mg / ml. Weigh 5...

Embodiment 2

[0039] Weigh A, B silica gel, YAG (Y 3 al 5 o 12 : Ce) Phosphor powder 5g, 5g, 1.5g, that is, the proportion is A:B:YAG=1:1:0.3, it is fully mixed evenly, after the mixed fluorescent glue is degassed and vacuumized, it is placed in the feed The cylinder is spin-coated on the PET film placed on the glass substrate. The acceleration of the first stage of the homogenizer is: 340rpm / s, the speed of the second stage of the uniform stage is: 420rpm / s, and the third stage is the stop stage. Both acceleration and acceleration are 0rpm / s, and the spin coating time is 160s. Afterwards, it was cured in an oven at 80°C for 20 minutes, and then cured at 150°C for 10 minutes. The second layer is the boron nitride layer. Before use, the boron nitride is ultrasonically oscillated for 30 minutes. The boron nitride is dispersed in isopropanol with a concentration of 2mg / ml. Weigh 5g of silica gel A and B respectively, and Boron isopropanol dispersion 2.5ml, mixed well, placed in a vacuum de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com