Cooling method for hot-pressing cast electronic ceramic blank

A technology of electronic ceramics and cooling method, applied in the direction of ceramic molding machine, manufacturing tools, etc., can solve the problems of affecting product quality, labor time consumption, water heat exchange speed reduction, etc., to avoid worker injury and contamination, and improve heat exchange Effect of speed, accelerated cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

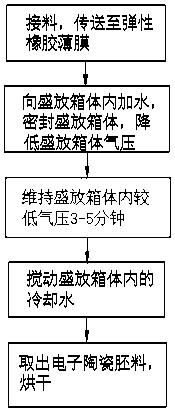

[0029] Embodiment 1, with reference to figure 1 , a method for cooling a hot-press injection electronic ceramic billet, comprising the following steps:

[0030] S1: A conveyor belt is installed under the billet outlet of the hot press injection molding machine, and a well-sealed storage box with a top cover is placed on the side of the conveyor belt away from the hot press injection molding machine;

[0031] S2: The electronic ceramic billet after hot pressing injection molding falls on the conveyor belt, and is transported to the top of the storage box by the conveyor belt. There is an elastic rubber film connected between the outer walls of the two sides of the storage box, and the electronic ceramic billet falls from the conveyor belt. on the elastic rubber membrane;

[0032] S3: Inject cooling water at 15°C into the storage box, and the liquid surface of the cooling water is immersed in the electronic ceramic blank;

[0033] S4: Cover the top cover of the storage box so ...

Embodiment 2

[0036] Embodiment 2, a cooling method for hot-press injection electronic ceramic blanks, comprising the following steps:

[0037] S1: A conveyor belt is installed under the billet outlet of the hot press injection molding machine, and a well-sealed storage box with a top cover is placed on the side of the conveyor belt away from the hot press injection molding machine;

[0038] S2: The electronic ceramic billet after hot pressing injection molding falls on the conveyor belt, and is transported to the top of the storage box by the conveyor belt. There is an elastic rubber film connected between the outer walls of the two sides of the storage box, and the electronic ceramic billet falls from the conveyor belt. on the elastic rubber membrane;

[0039] S3: Inject cooling water at 20°C into the storage box, and the liquid surface of the cooling water is immersed in the electronic ceramic blank;

[0040] S4: Cover the top cover of the storage box so that the inside of the storage b...

Embodiment 3

[0043] Embodiment 3, a method for cooling a hot-press injected electronic ceramic blank, comprising the following steps:

[0044] S1: A conveyor belt is installed under the billet outlet of the hot press injection molding machine, and a well-sealed storage box with a top cover is placed on the side of the conveyor belt away from the hot press injection molding machine;

[0045] S2: The electronic ceramic billet after hot pressing injection molding falls on the conveyor belt, and is transported to the top of the storage box by the conveyor belt. There is an elastic rubber film connected between the outer walls of the two sides of the storage box, and the electronic ceramic billet falls from the conveyor belt. on the elastic rubber membrane;

[0046] S3: Inject cooling water at 25°C into the storage box, and the liquid surface of the cooling water is immersed in the electronic ceramic blank;

[0047] S4: Cover the top cover of the storage box so that the inside of the storage box...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com