Anti-blue ray resin composition and preparation method thereof

A resin composition, anti-blue light technology, applied in optics, optical components, coatings, etc., can solve the problem of short- and medium-wavelength blue light irradiating the human eye, and achieve improved service life, simple preparation process, and wide application range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

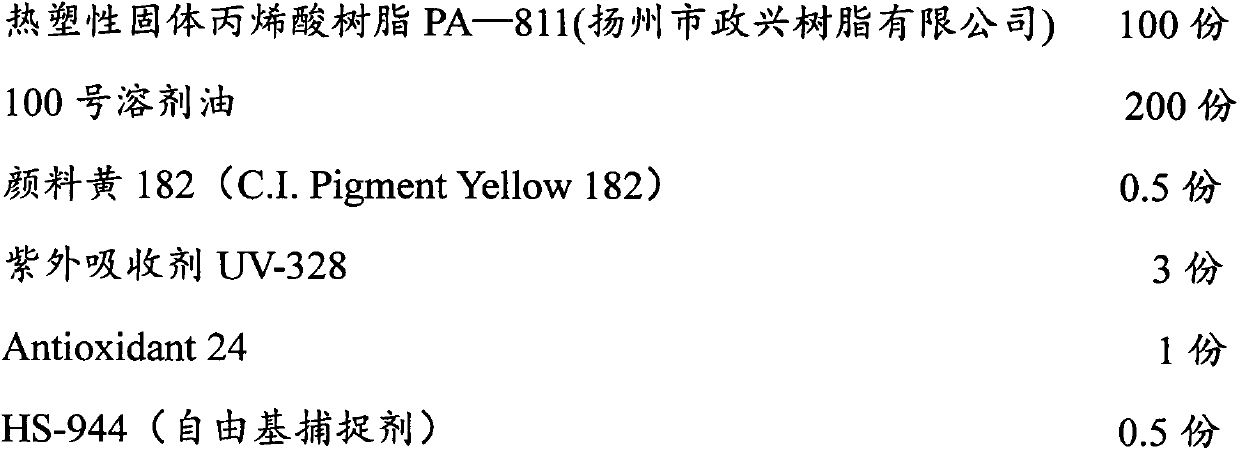

[0024]

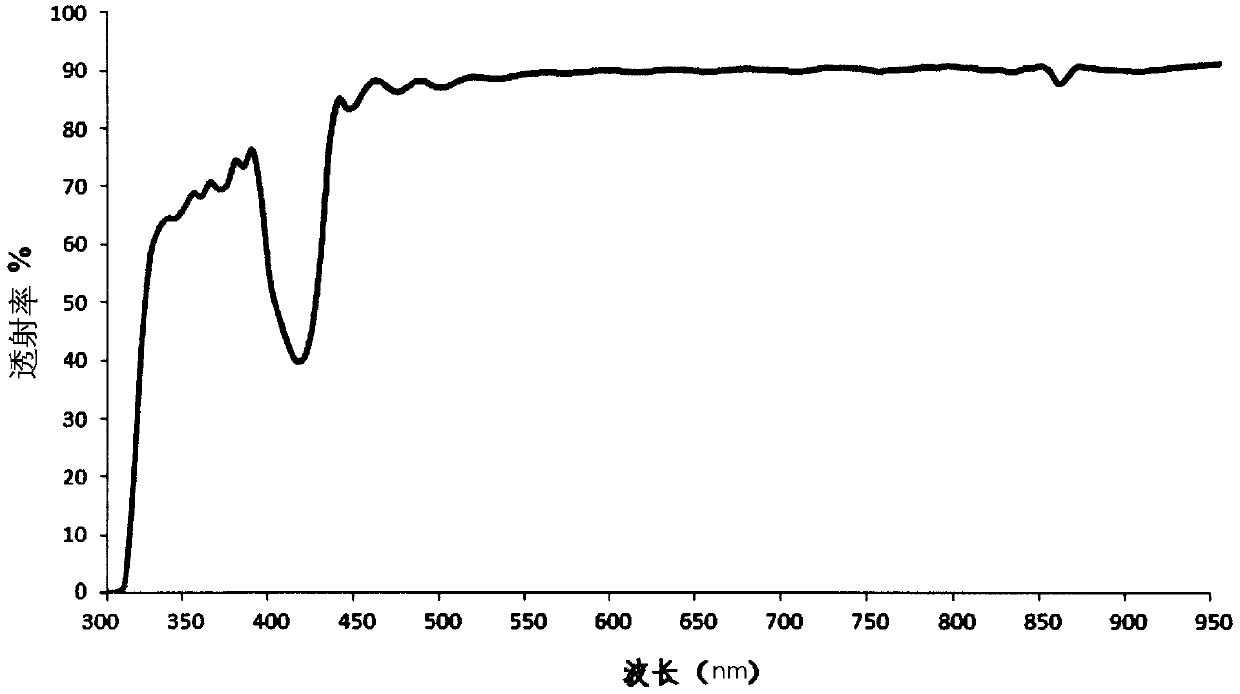

[0025] The prepared anti-blue light coating solution is coated on a PET substrate, and after drying at 80° C. for 3 minutes, a PET film with anti-blue light function can be obtained.

Embodiment 2

[0027]

[0028] The prepared anti-blue light coating solution is coated on a glass substrate and dried at 75°C for 4 minutes to obtain a glass screen with anti-blue light function.

Embodiment 3

[0030]

[0031] The prepared anti-blue light coating solution is coated on the PP substrate, and after drying at 75°C for 4 minutes, a PP film with anti-blue light function can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com