Economical high-aluminum and low-silicon TRIP steel for automobiles and preparation method of TRIP steel

A technology of elongation and mass percentage, which is applied in the field of economical high-aluminum low-silicon TRIP steel for automobiles and its preparation, can solve the problems of reduced solid solution strengthening effect, low steel strength, and unsatisfactory, and achieve high recycling rate of steel , low alloy composition and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

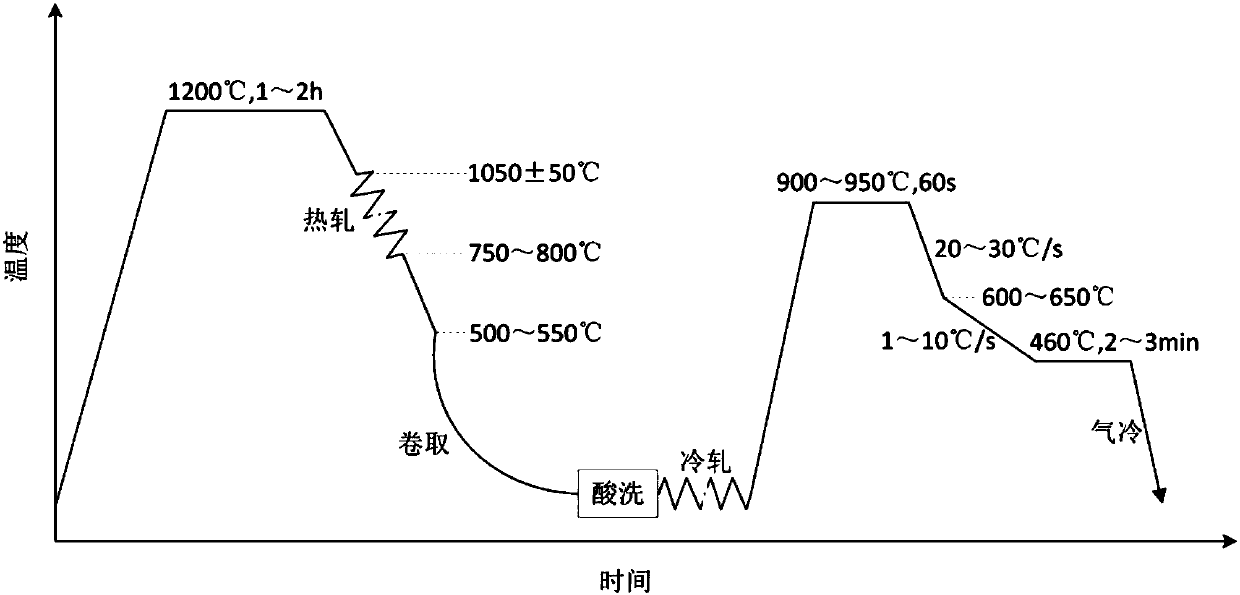

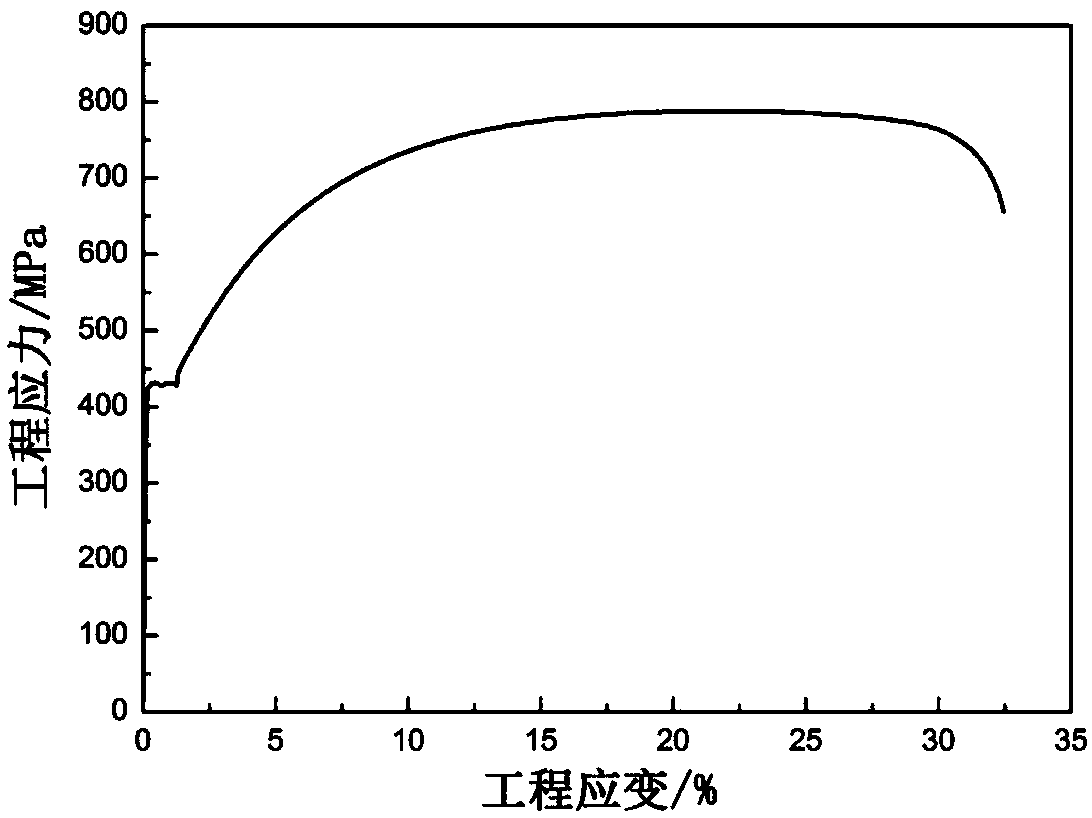

[0036] In this example, the material is prepared according to the composition design ratio, and the vacuum induction furnace is melted and poured quickly at 1600 ° C. The actual mass percentage of the steel composition is: C: 0.19%, Si: 0.36%, Al: 1.59%, Mn: 1.57% , Cu: 0.37%, P: 0.004%, S: 0.0029%, and the balance is Fe, and then the ingot is heated to 1100°C and forged into a 60mm thick rectangular block. Heat the rectangular steel block to 1200°C for 2 hours, air-cool to 1050°C to start hot rolling, and measure the final rolling temperature to 780°C when it reaches a thickness of 6 mm, then air-cool to 550°C for coiling. The cold-rolled sheet is pickled and then cold-rolled, and the reduction is controlled at 70% to obtain a cold-rolled sheet with a thickness of 1.6 mm.

[0037] Next, the cold-rolled sheet after edge trimming is hydrogenated with 5% H 2 +N 2 Annealing was performed in a mixed atmosphere. First heat the cold-rolled sheet to 930°C, keep it warm for 60s, th...

Embodiment 2

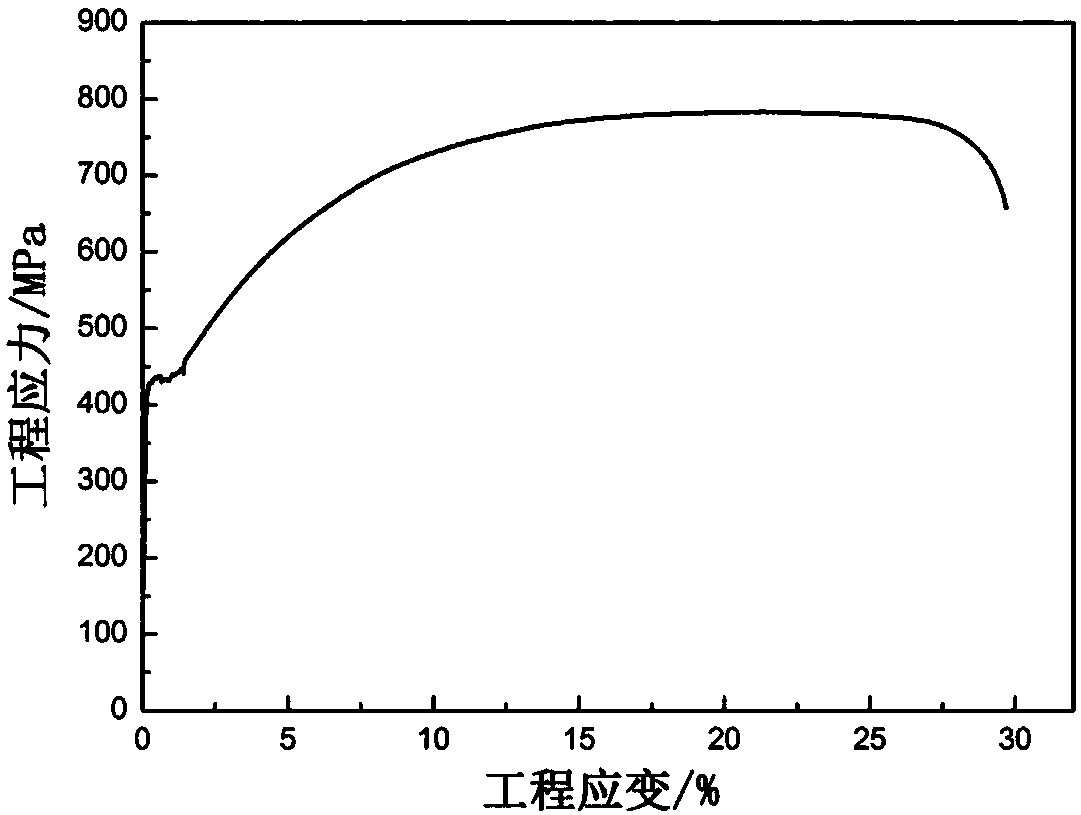

[0039] In this example, the material is prepared according to the composition design. After melting in the vacuum induction furnace, it is quickly poured at 1620 ° C. The actual mass percentage of the steel composition is: C: 0.22%, Si: 0.43%, Al: 1.61%, Mn: 1.86% , Cu: 0.42%, P: 0.0072%, S: 0.0074%, and the balance is Fe, and then the ingot is heated to 1100°C and forged into a 60mm thick rectangular block. Heat the rectangular steel block to 1200°C for 1.5h, air-cool to 1100°C and start hot rolling. When the thickness reaches 6.2mm, the final rolling temperature is 800°C, and then air-cool to 560°C for coiling. The cold-rolled sheet is pickled and then cold-rolled, and the reduction is controlled at 70% to obtain a cold-rolled sheet with a thickness of 1.7 mm.

[0040] Next, the cold-rolled sheet after edge trimming is hydrogenated with 5% H 2 +N 2Annealing was performed in a mixed atmosphere. First heat the cold-rolled sheet to 950°C, keep it warm for 60s, cool it to 650...

Embodiment 3

[0042] In this example, the material is prepared according to the composition ratio, and the vacuum induction furnace is melted and poured quickly at 1650 ° C. The actual mass percentage of the steel composition is: C: 0.23%, Si: 0.43%, Al: 1.72%, Mn: 1.87% , Cu: 0.56%, P: 0.0064%, S: 0.0062%, and the balance is Fe, and then the ingot is heated to 1100°C and forged into a 60mm thick rectangular block. Heat the rectangular steel block to 1200°C for 1.5h, air-cool to 1030°C and start hot rolling. When the thickness reaches 6mm, the final rolling temperature is 770°C, and then air-cool to 530°C for coiling. The cold-rolled sheet is pickled and then cold-rolled, and the reduction is controlled at 70% to obtain a cold-rolled sheet with a thickness of 1.6 mm.

[0043] Next, the cold-rolled sheet after edge trimming is hydrogenated with 5% H 2 +N 2 Annealing was performed in a mixed atmosphere. First heat the cold-rolled sheet to 930°C, keep it warm for 60s, cool it to 650°C at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com