Self-cleaning double-needle injection needle assembly for saline injection machine

A salt water injection machine, self-cleaning technology, applied in the directions of cleaning hollow objects, cleaning methods and utensils, climate change adaptation, etc., can solve the problems of reducing the probability of injection needle blockage, unable to solve the problem of needle blockage, and large space occupied by spreader feet, etc. Achieve the effect of improving quality and quality stability, suitable for promotion, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific embodiments and drawings.

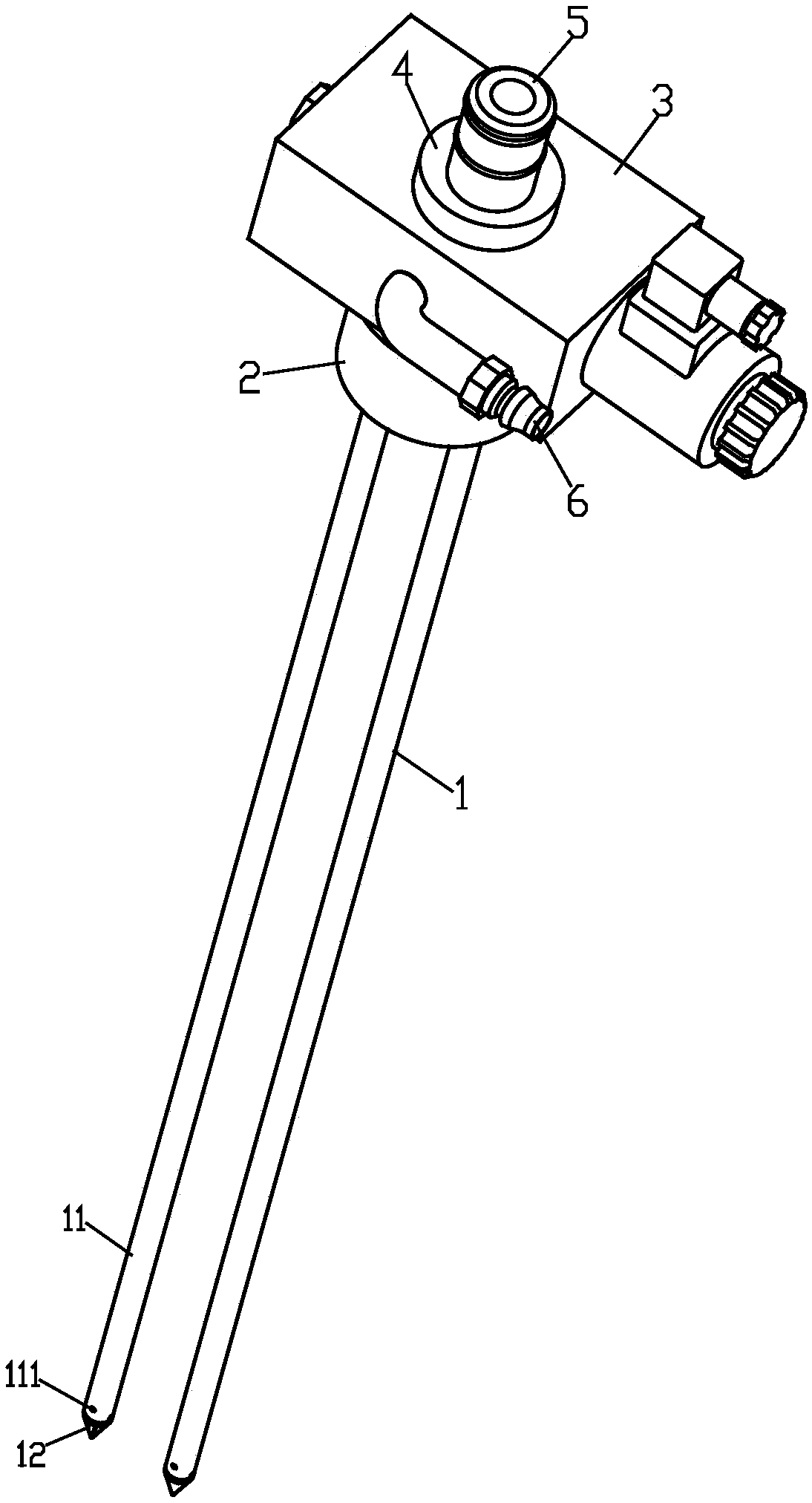

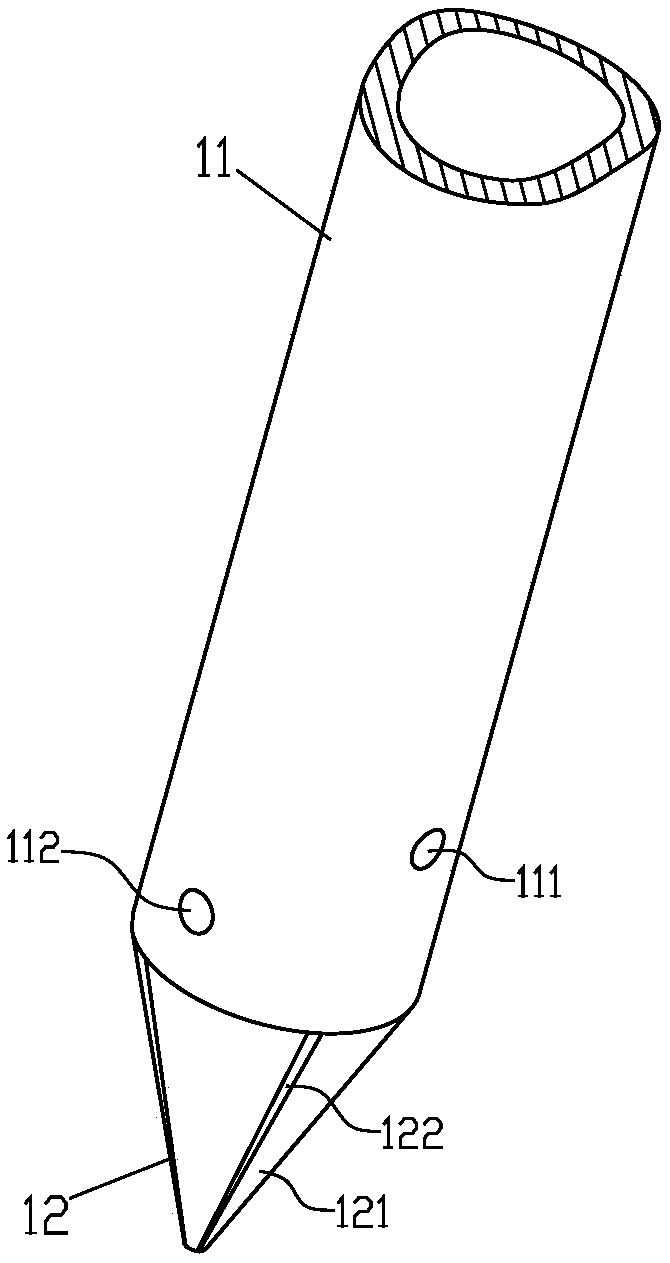

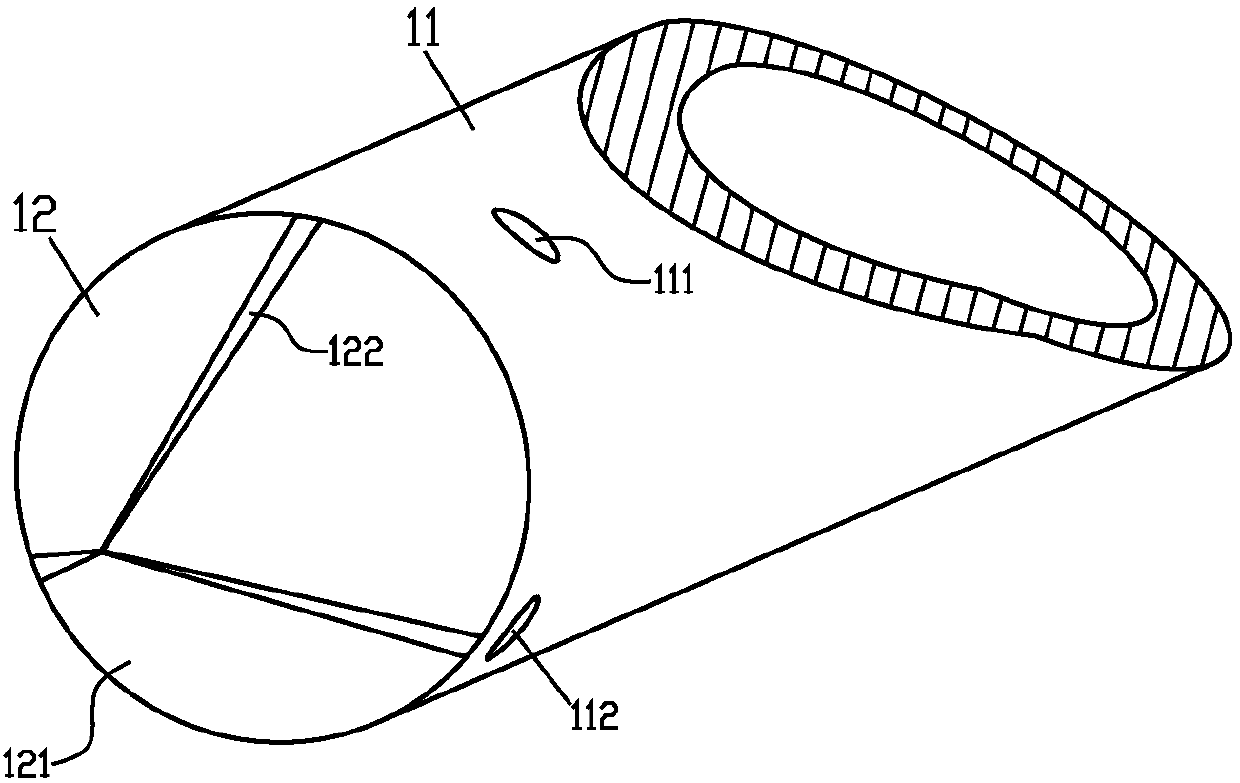

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, a self-cleaning double-ended injection needle for a saline injection machine includes a needle 1, a solution dispenser 2, an electromagnetic reversing valve 3, a load cell 4, a solution injection pipe joint 5, and a detergent injection pipe joint 6. Wherein, there are two needles 1 and are arranged in parallel below the solution distributor 2 for injecting the prepared aqueous solution into the meat product. The upper end of the needle 1 and the bottom of the solution distributor 2 are welded Method of fixed connection; the solution dispenser 2 is fixedly installed at the bottom of the electromagnetic reversing valve 3 for dispensing aqueous solution t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com