Production system of fiber reinforced composite product

A fiber reinforced, composite material technology, applied in the coating and other directions, can solve the problems of reduced strength, inability to recycle, long molding cycle, etc., to achieve the effect of easy bending and molding, eliminating the granulation process, and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

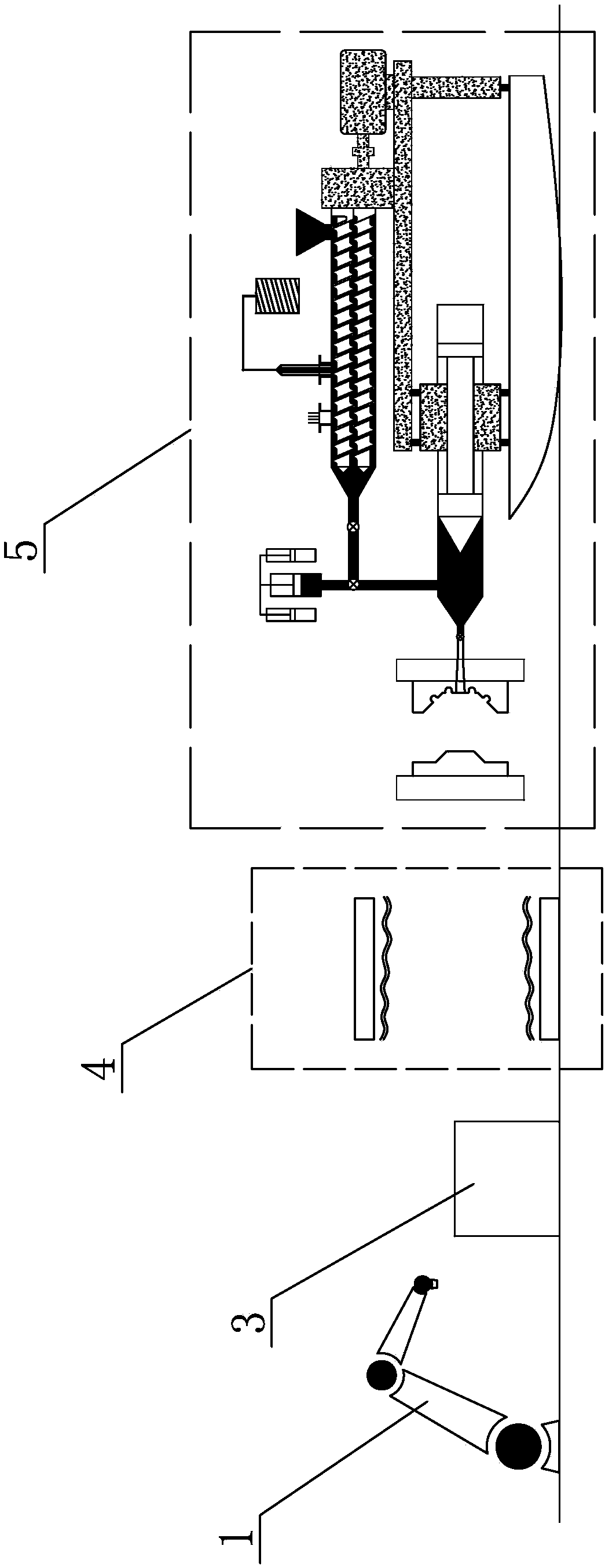

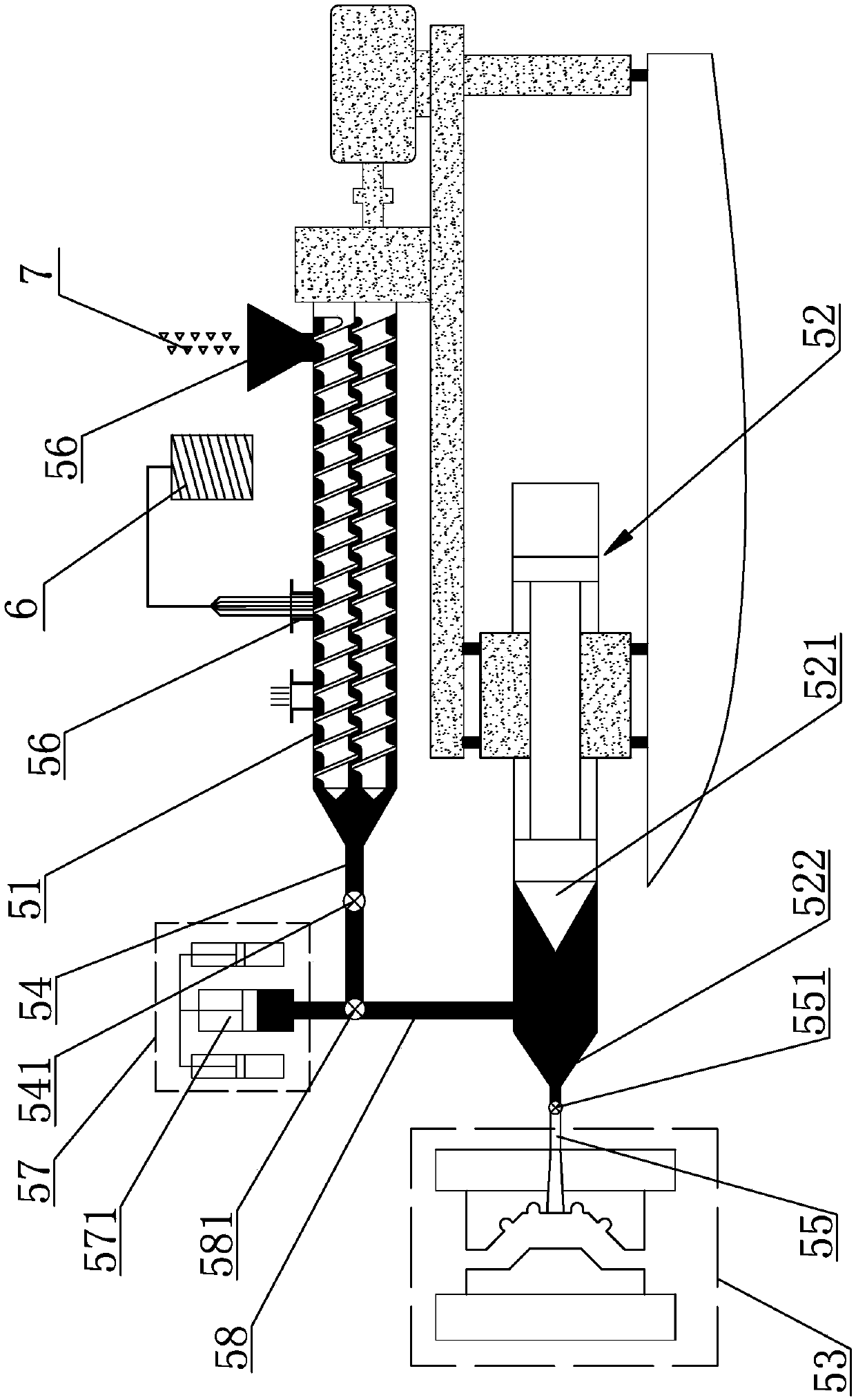

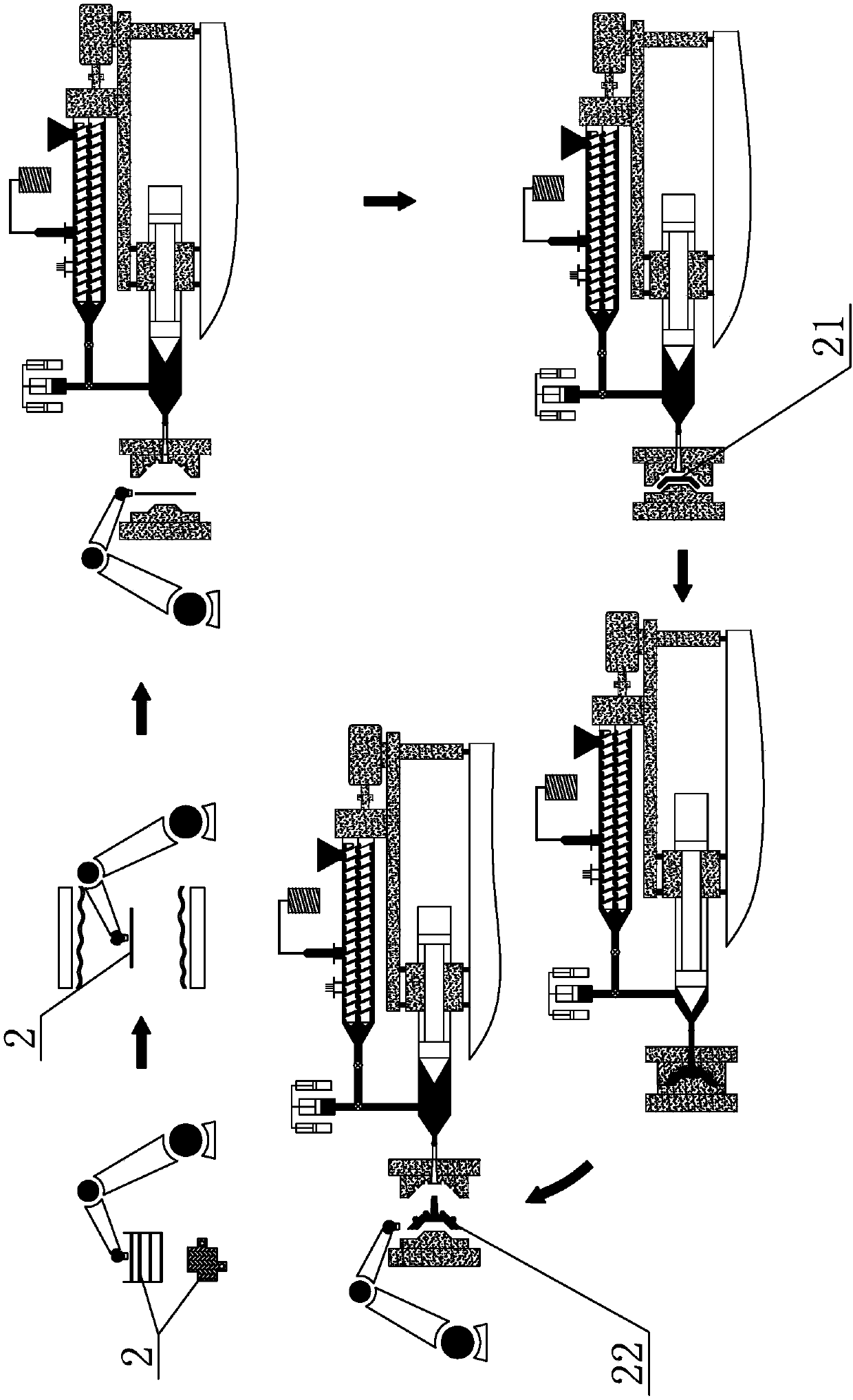

[0020] Such as figure 1 , figure 2 As shown, a production system for fiber-reinforced composite products includes a mobile manipulator 1 and a reclaiming station, a preheating station, an injection molding station and a blanking station arranged in sequence along the moving direction of the mobile manipulator 1, The material storage area 3 for storing the semi-formed fiber sheet 2 is set on the retrieving station, the heating device 4 for preheating the fiber sheet 2 is arranged on the preheating station, and the online mixing injection molding station is arranged on the injection molding station. device 5.

[0021] In this specific embodiment, the semi-formed fiber sheet 2 is a fiber-reinforced composite laminate formed by laminating and pressing continuous fiber woven cloth and resin impregnated. Semi-formed fiber sheet 2 is made of fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com