A kind of automobile b-pillar reinforcement plate and its manufacturing method

A manufacturing method and reinforcing plate technology, applied in the field of auto parts, can solve problems such as the inability of people in the car to escape, the door can not be opened normally, the injury of people in the car, etc., and achieve the effects of light weight, not easy to deform, and avoid injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

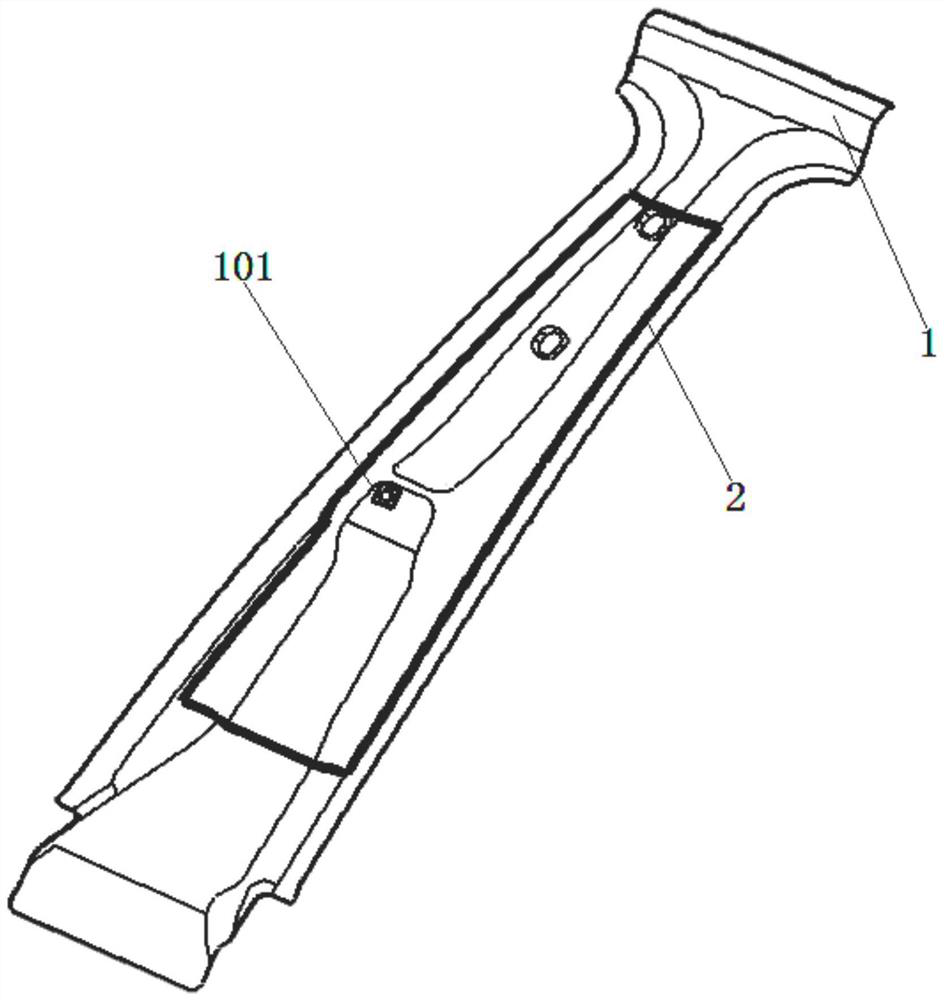

[0066] This embodiment provides an automobile B-pillar reinforcement plate, which is manufactured by the following method:

[0067] The DC04 steel is placed in the stiffener shell mold for stamping to obtain a stiffener shell 1 with a thickness of 1.2 mm.

[0068] The carbon fiber composite material is molded by resin transfer molding technology, and the carbon fiber cloth of model T300 is laid into 11 layers in the mold of the inner reinforcement plate, and the laying angles are 90°, 90°, 45°, 0°, -45°, -45°, -45°, 0°, 0°, 45°, 45°. Subsequently, the mold is closed, and the amount ratio of 5.5:4.5 is injected into the mold of the inner layer reinforcing plate, and the epoxy resin and the curing agent of the models EPON135 and EPON1366 are respectively formed to form a cured inner layer reinforcing plate 2. The cured inner layer reinforcing plate 2 was demoulded to obtain an inner layer reinforcing plate 2 with a thickness of 2.2 mm.

[0069] Subsequently, place the inner re...

Embodiment 2

[0075] The DC04 steel is placed in the stiffener shell mold for stamping to obtain a stiffener shell 1 with a thickness of 1 mm.

[0076] The carbon fiber composite material is molded by resin transfer molding technology, and the carbon fiber cloth of the model T300 is laid in 10 layers in the inner reinforcement plate mold, and the laying angles are 90°, 90°, 45°, 0°, -45°, -45°, -45°, 0°, 0°, 45°. Subsequently, the mold is closed, and an epoxy resin and a curing agent of EPON135 and EPON1366 are injected into the inner layer reinforcement plate mold with a dosage ratio of 5:4 to form a cured inner layer reinforcement plate 2. The cured inner layer reinforcing plate 2 is demolded to obtain an inner layer reinforcing plate 2 with a thickness of 2 mm.

[0077] Subsequently, place the inner reinforcement board 2 in the opening groove of the reinforcement board shell 1, and use DP420 adhesive to glue the reinforcement board shell 1 and the inner layer reinforcement board 2 toget...

Embodiment 3

[0079] The DC04 steel is placed in the stiffener shell mold for stamping to obtain a stiffener shell 1 with a thickness of 1.5 mm.

[0080] The carbon fiber composite material is molded by resin transfer molding technology, and the carbon fiber cloth of model T300 is laid into 12 layers in the mold of the inner reinforcement plate, and the laying angles are 90°, 90°, 45°, 0°, -45°, -45°, -45°, 0°, 0°, 45°, 45°, 45°. Subsequently, the mold is closed, and the amount ratio of 6:5 is injected into the inner layer reinforcing plate mold, and the epoxy resin and curing agent of the models EPON135 and EPON1366 are respectively formed to form a cured inner layer reinforcing plate 2, and the The cured inner layer reinforcing plate 2 is demolded to obtain an inner layer reinforcing plate 2 with a thickness of 2.5 mm.

[0081] Subsequently, place the inner reinforcement board 2 in the opening groove of the reinforcement board shell 1, and use DP420 adhesive to glue the reinforcement boa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com