High-strength and radiation-proof pumpable concrete and preparation method thereof

A technology for pumping concrete and concrete, applied in the field of concrete, can solve problems such as difficult pumpability, achieve good pumpability, reduce shrinkage cracks, and improve strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

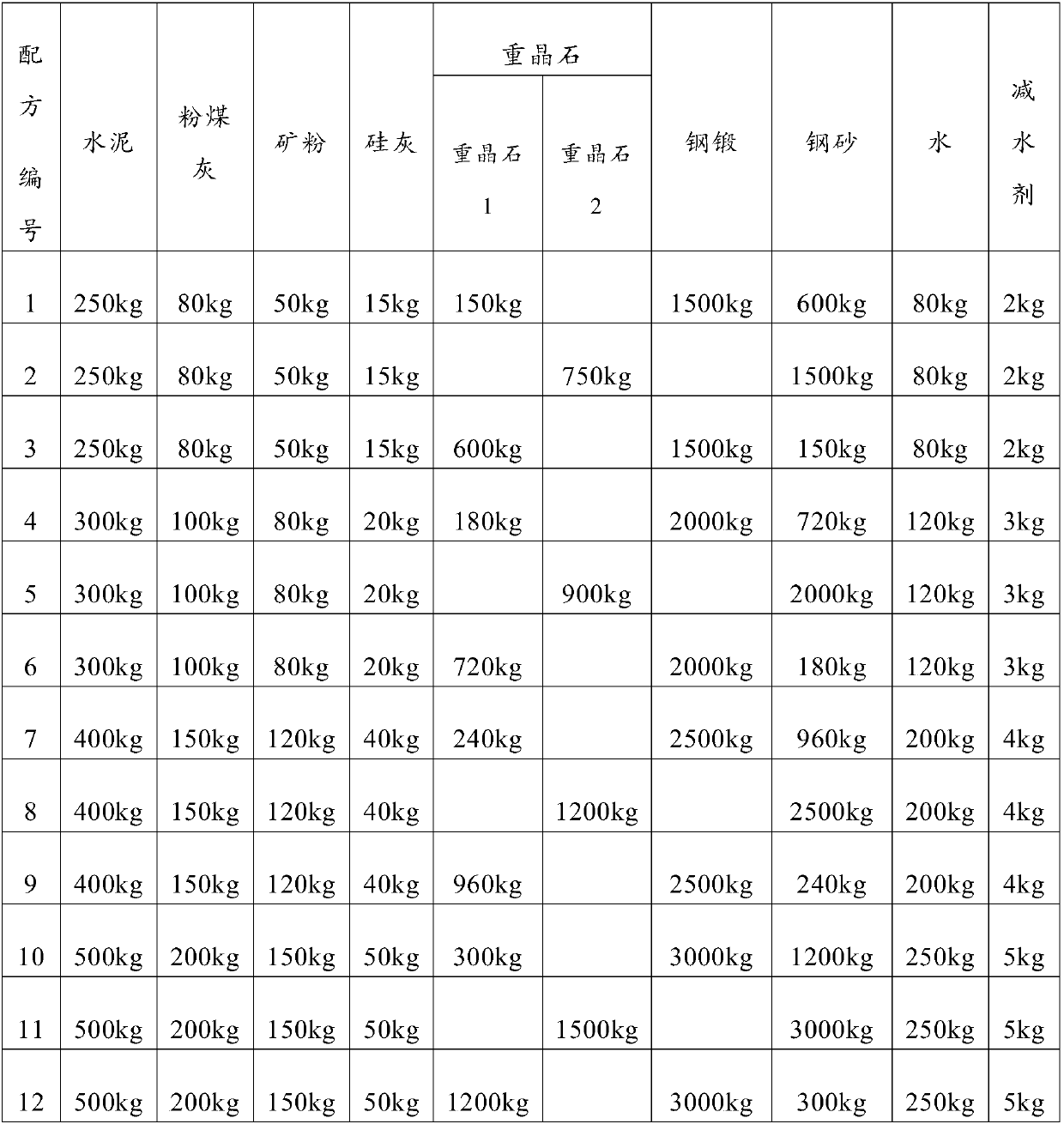

[0037] Embodiment 1: the preparation of different formula concrete

[0038] Concrete with different formulations was prepared according to the raw material composition and dosage in Table 1 below. Among the raw materials used: cement is Po42.5 grade, fly ash is grade 1, mineral powder is S95 grade, silica fume is 92 grade, barite 1 is barite sand with fineness modulus 2.3-3.0, heavy The spar 2 is barite with an average particle size of 5-20mm, the steel forging is continuously graded steel forging of 5-20mm, the steel grit is steel grit with a fineness modulus of 2.3-3.0, and the water reducing agent is polycarboxylate water reducing agent. agent.

[0039] The preparation method of the concrete of each formula is as follows:

[0040] (1) Under stirring, add cement, fly ash, mineral powder, silica fume, barite, steel forging, steel sand to the mixer, and stir for 30 seconds until the coarse and fine aggregates are evenly mixed;

[0041] (2) Add 50% of the required amount of ...

Embodiment 2

[0045] Embodiment 2: the performance detection of each formula concrete of preparation gained

[0046] The concrete of each formula prepared in Example 1 was tested for concrete strength (method and classification see GB / T50081-2002, GB50010-2010), degree of expansion and slump (method see GBT 14902-2012), and the obtained results are shown in the following table 2.

[0047]Table 2 embodiment 1 prepares the performance detection result of each formula concrete of gained

[0048] recipe number

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com