Preparation method of anti-yellowing waterborne polyurethane coating

A technology of water-based polyurethane and anti-yellowing technology, which is applied in the field of preparation of water-based coatings. It can solve the problems of high price, poor solvent resistance and abrasion resistance, and low mechanical strength of polyurethane, and achieve strong ultraviolet shielding effect, good hydrolysis resistance, Effect of improving tensile strength and mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

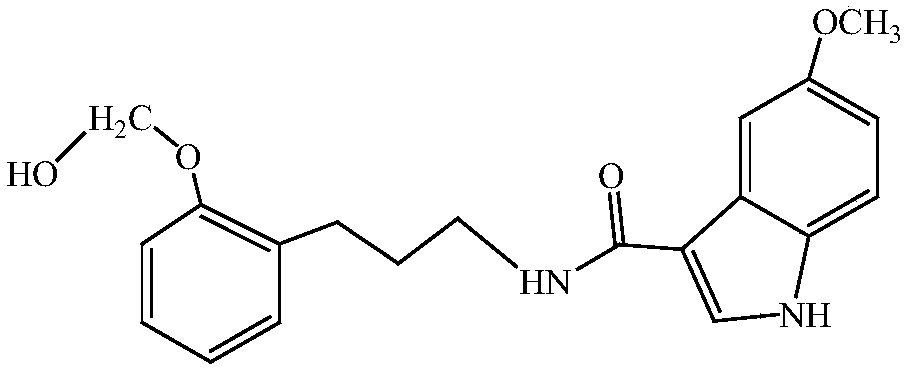

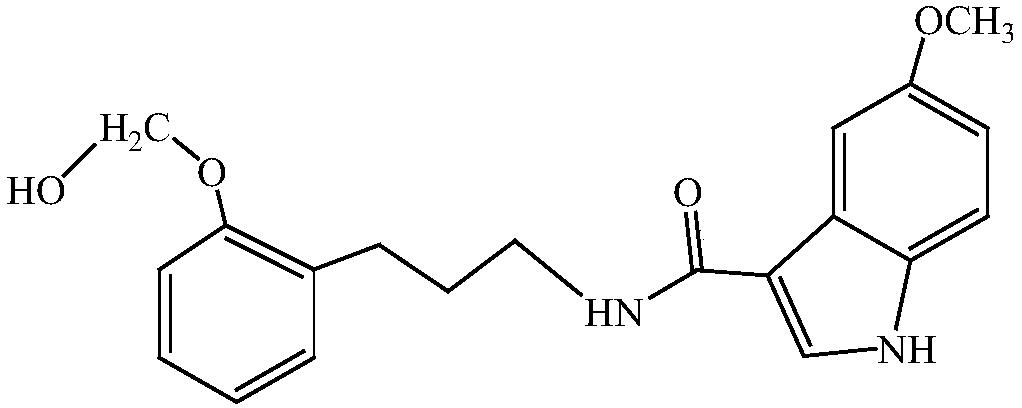

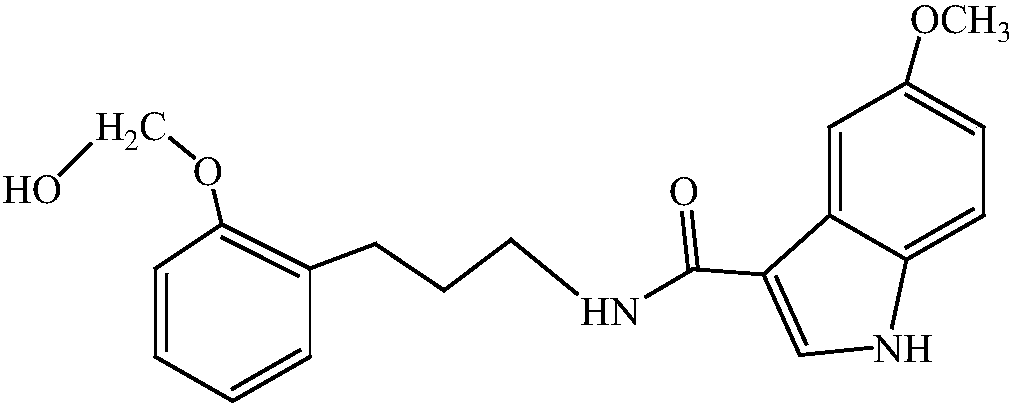

Image

Examples

Embodiment 1

[0028] A preparation method of anti-yellowing water-based polyurethane coating, wherein it is carried out according to the following steps:

[0029] 1) In the presence of a triethylenediamine catalyst, mix polytetrahydrofuran diol and polyisocyanate at a molar ratio of NCO / OH of 3:1, and react at 70° C. for 2 hours to obtain a polyurethane prepolymer; The amount of the catalyst is 0.2% of the total mass of polytetrahydrofuran diol and polyisocyanate;

[0030] 2), add 3% of the total weight of the polyurethane prepolymer hydrophilic chain extender and 12% of the total weight of the polyurethane prepolymer butanone solvent to the polyurethane prepolymer, react at 70°C for 2h, add triethylamine to The prepolymer was neutralized for 20 minutes, and water was added to emulsify to form a hydrophilic polytetrahydrofuran polyurethane for later use;

[0031] 3) Add 0.5% dispersant of ultrafine quartz powder solution mass concentration to the ultrafine quartz powder solution with a mas...

Embodiment 2

[0044] A preparation method of anti-yellowing water-based polyurethane coating, wherein it is carried out according to the following steps:

[0045] 1) In the presence of a triethylenediamine catalyst, mix polytetrahydrofuran diol and polyisocyanate at a molar ratio of NCO / OH of 5:1, and react at 70° C. for 23 hours to obtain a polyurethane prepolymer; The amount of the catalyst is 0.2% of the total mass of polytetrahydrofuran diol and polyisocyanate;

[0046] 2), add 5% of the total weight of the polyurethane prepolymer hydrophilic chain extender and 12% of the total weight of the polyurethane prepolymer butanone solvent to the polyurethane prepolymer, react at 70°C for 2h, add triethylamine The prepolymer was neutralized for 20 minutes, and water was added to emulsify to form a hydrophilic polytetrahydrofuran polyurethane for later use;

[0047]3) Add a dispersant with a mass concentration of 1% of the ultrafine quartz powder solution to the ultrafine quartz powder solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap