Imidazole modified laccase composite soaping agent and preparation method thereof

A technology for modifying and compounding soaps, which is applied in dyeing, textiles and papermaking, etc. It can solve the problems of inability to maintain, high vitality and stability, reduce costs, improve stability and activity, and reduce anti-sticking rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

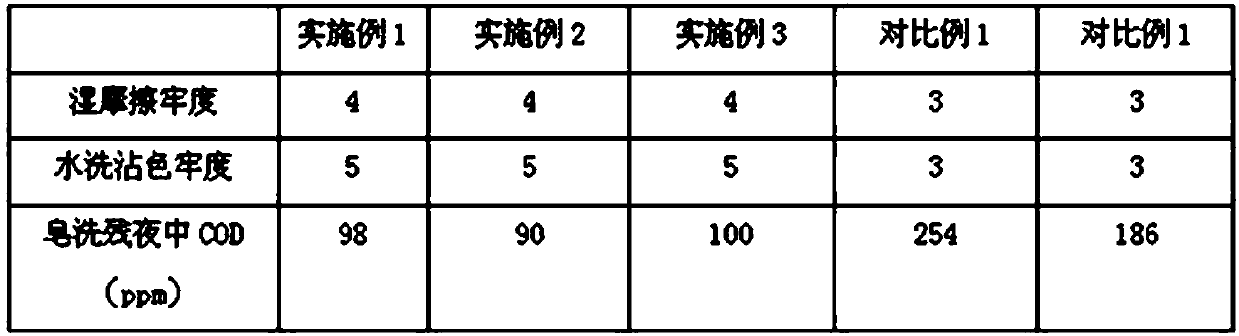

Examples

Embodiment 1

[0014] Imidazole-modified modified laccase composite soaping agent, including laccase, active agent, imidazole, auxiliary agent and deionized water, the weight ratio of laccase, active agent, imidazole, auxiliary agent and deionized water is 40:1: 2:1:20; the active agent includes the following components in parts by weight: 12 parts of copper foam, 1 part of nano silicon dioxide, 2 parts of rare earth salt, and 12 parts of hydrophilic polymer compound.

[0015] Wherein, the particle size of the copper foam is 25-40nm.

[0016] The auxiliary agent is a mixture of softening agent and antistatic agent, and the weight ratio of the two is 2:1.

[0017] The preparation method of the above-mentioned imidazole-modified modified laccase composite soaping agent, step 1, prepare 0.01mmol / mL surfactant aqueous solution, at room temperature, drop the laccase solution while stirring until clarification, to obtain a mixed solution; step 2, add to Add the active agent dropwise while stirrin...

Embodiment 2

[0019] Imidazole-modified modified laccase composite soaping agent, including laccase, active agent, imidazole, auxiliary agent and deionized water, the weight ratio of laccase, active agent, imidazole, auxiliary agent and deionized water is 48:2: 2-5: 3: 25; the active agent includes the following components in parts by weight: 20 parts of copper foam, 2 parts of nano silicon dioxide, 3 parts of rare earth salt, and 15 parts of hydrophilic polymer compound.

[0020] Wherein, the particle size of the copper foam is 25-40nm.

[0021] The auxiliary agent is a mixture of softening agent and antistatic agent, and the weight ratio of the two is 2:1.

[0022] The preparation method of the above-mentioned imidazole-modified modified laccase composite soaping agent, step 1, prepare 0.08mmol / mL surfactant aqueous solution, at room temperature, drop the laccase solution while stirring until clarification, to obtain a mixed solution; step 2, add to Add the active agent dropwise while st...

Embodiment 3

[0024] Imidazole-modified modified laccase composite soaping agent, comprising laccase, active agent, imidazole, auxiliary agent and deionized water, the weight ratio of laccase, active agent, imidazole, auxiliary agent and deionized water is 40-60: 1-3: 2-5: 1-5: 20-34; the active agent includes the following components by weight: 12-24 parts of copper foam, 1-3 parts of nano silicon dioxide, 2- 4 parts, 12-18 parts of hydrophilic polymer compound.

[0025] Wherein, the particle size of the copper foam is 25-40nm.

[0026] The auxiliary agent is a mixture of softening agent and antistatic agent, and the weight ratio of the two is 2:1.

[0027] The preparation method of the above-mentioned imidazole-modified modified laccase composite soaping agent, step 1, prepare 1mmol / mL surfactant aqueous solution, at room temperature, add dropwise laccase solution to clarification while stirring to obtain a mixed solution; step 2, add to the mixture Add the active agent dropwise while s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com