Assembled concrete tower silo construction method

A construction method and concrete technology, which is applied in the direction of construction, building structure, and construction material processing, etc., can solve the problems of increasing the working hours of construction personnel, high energy consumption of cast-in-place construction, and high requirements for the construction environment, so as to solve the problems on site The effect of resource conflict, shortening construction period, and eliminating safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

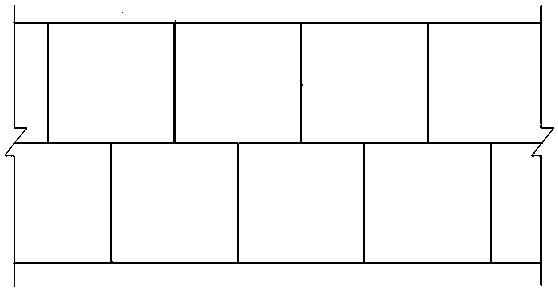

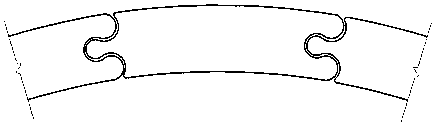

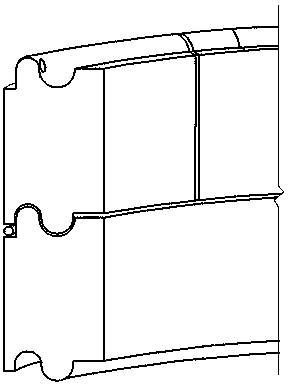

[0025] like figure 1 , figure 2 , image 3 As shown, the construction method of the assembled concrete circular silo of the present invention comprises the following steps:

[0026] (1) Prefabricated silo wall concrete modules: According to the perimeter, height, and force characteristics of the silo wall, and comprehensively considering the conditions of lifting, transportation, and assembly, the geometric shape and size of the prefabricated modules of the silo wall are reasonably designed, and BIM technology is applied Realize simulated assembly, use the plastic model one-time forming process to manufacture the clear-faced concrete module of the warehouse wall, and use steam curing after the manufacture is completed;

[0027] (2) The warehouse wall concrete modules are hoisted in place and installed and fixed: the prefabricated warehouse wall fair-faced concrete modules are arranged in a staggered manner first down and then up, and are hoisted from far to near, and there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com