A special large-diameter sand filling model device and method for physical simulation experiments

A technology of physical simulation and model device, which is applied in the preparation of test samples, earthwork drilling, wellbore/well components, etc., which can solve the problem of low compressive strength, limited field condition simulation, and inability to simulate edge and bottom well Water and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

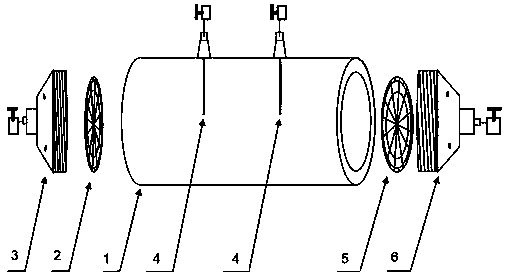

Embodiment 1

[0057] Take the formula listed in Table 1 below as an example. Weigh the quartz sand and clay of different particle groups according to the proportion, and perform wettability treatment on the surface of part of the quartz sand according to the need, so as to achieve the mixed wetting effect. According to the above scheme, a sand filling model was made and a conventional water flooding + injection-production coupling + gas-water dual drive experiment was carried out. The sealing cap 3 at the left pipe end is in the lower part, and the injection-production well hole 4 simulates the simple injection-production unit of the oil reservoir, which is close to the left pipe The well hole (lower part) of the end sealing cover 3 is used as the water injection well, the well hole (upper part) near the right pipe end sealing cover 6 is used as the production well, and the left and right ends of the model can be used as pressure monitoring points. Water flooding to 95% water cut, calculate ...

Embodiment 2

[0061] The formula listed in Table 2 below is taken as an example, and the quartz sand and clay of different particle groups are weighed in proportion, and the surface of the quartz sand is subjected to wettability treatment according to the research needs, so as to achieve the lipophilic wetting effect. According to the above scheme, a sand filling model was made to carry out chemical agent evaluation experiments. The inclination angle of the model was less than 10°. The sealing cap 3 at the left pipe end was in the lower part. The injection-production well hole 4 simulated the simple injection-production unit of the oil reservoir, and was close to the sealing cap 3 at the left pipe end. The wellbore (lower part) of the model is used as an injection well, the wellbore (upper part) close to the right pipe end sealing cover 6 is used as a production well, and the left and right ends of the model can be used as pressure monitoring points. The injection end uses a high-precision I...

Embodiment 3

[0065] The formula listed in Table 3 below is taken as an example, and the quartz sand and clay of different particle groups are weighed in proportion, regardless of the wetting of the rock surface. Due to the characteristics of quartz sand, the wettability of the model should be strongly hydrophilic. According to the above scheme, a sand-filling model was made to carry out edge water flooding experiments. The inclination angle of the model was less than 5°. The left pipe end sealing cap 3 was at the lower part. The wellbore (upper part) is used as the production well, and the wellbore (lower part) at the right end of the model and the sealing cover 3 near the left pipe end is used as the pressure monitoring point. Investigating the production effect of the pure edge water flooding development strategy, the dry weight of sand filling is 102.4 kg, the pore volume is 4219.6 ml, the saturated simulated oil is 3567.7 ml, the initial oil saturation is 84.55%, and the simulated dip ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com