Method for producing desulfurization and denitrification hollow activated carbon

A production method, desulfurization and denitrification technology, applied in separation methods, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as uneven activation inside and outside, high cost of use, unstable indicators, etc., and achieve good market application value and save energy. The effect of resource and adsorption index stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for producing hollow activated carbon for desulfurization and denitrification, comprising the steps of:

[0034] (1) Grinding: put bituminous coal, coking coal, coke powder, and asphalt into the pulverizer in a weight ratio of 30:30:25:10 for grinding, and the particle size requires 325 mesh and 70% pass;

[0035] (2) Mixing: Mix the ground carbon powder, coal tar, and water in a weight ratio of 80:10:15, and the mixing temperature is 35°C to 40°C;

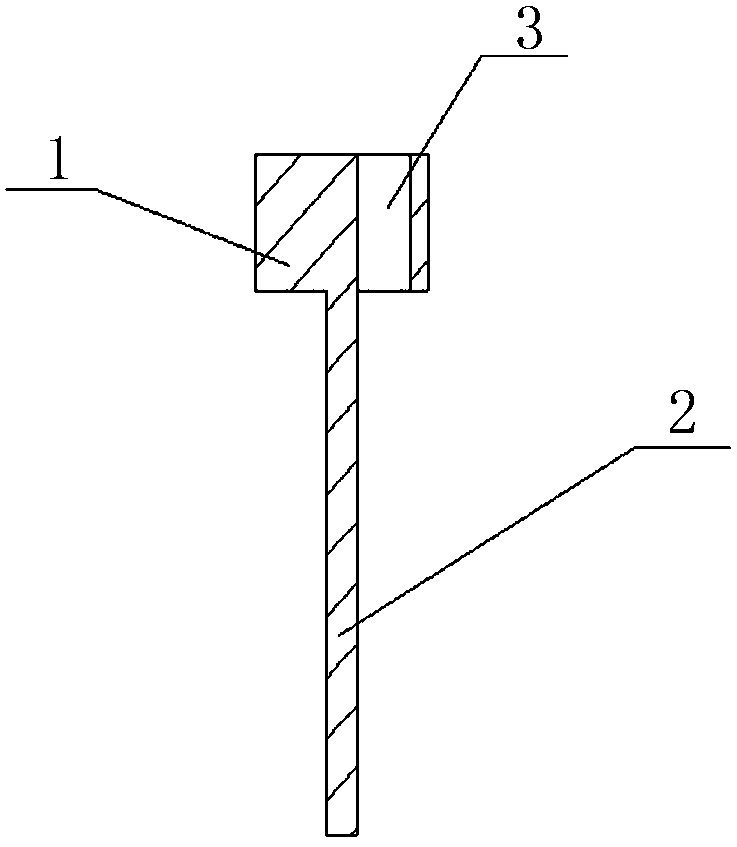

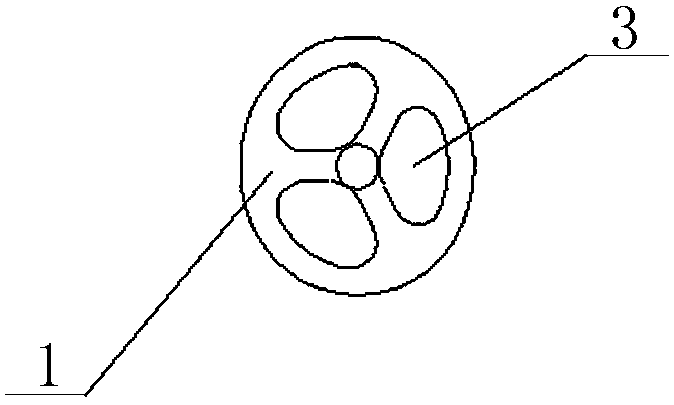

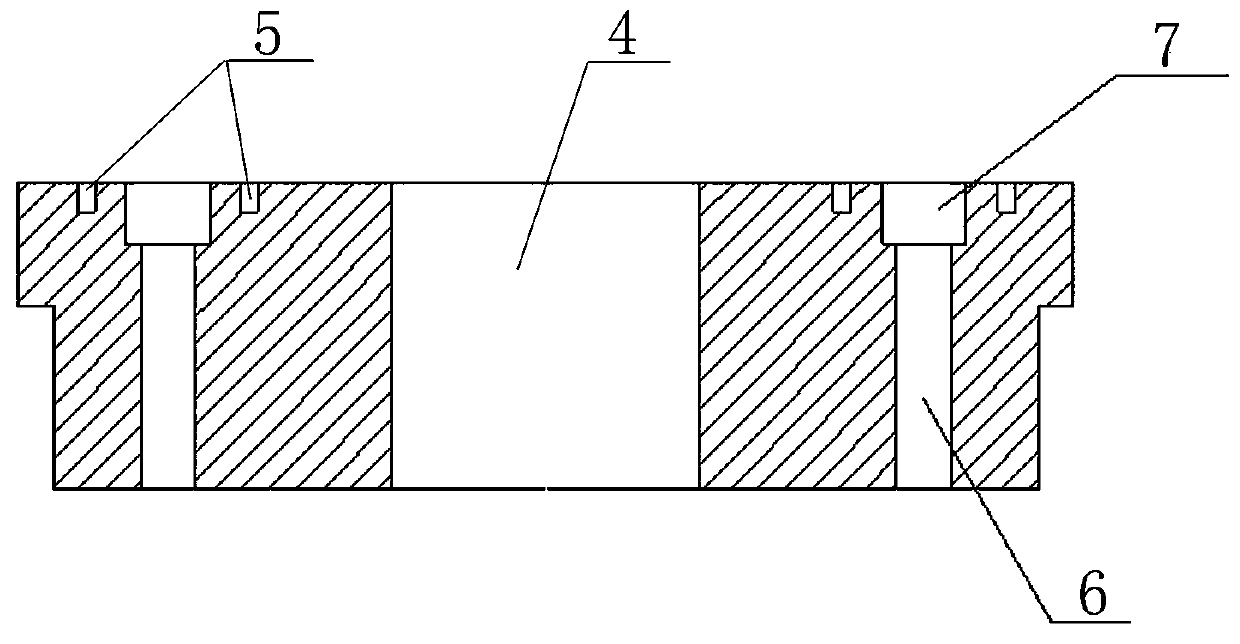

[0036] (3) Granulation: add the mixture into the mold to make hollow activated carbon raw material, the outer diameter of the hollow activated carbon raw material is 9.0-10.0mm, and the inner diameter is 2-3mm; then the hollow activated carbon raw material is cut into the required length by a cutter as pellets;

[0037] (4) Drying: The granulated material is dried in a dryer at a drying temperature of 90°C~95°C;

[0038] (5) Carbonization: Put the dry material into the converter for carbonization, the temperature...

Embodiment 2

[0043] A method for producing hollow activated carbon for desulfurization and denitrification, comprising the steps of:

[0044] (1) Grinding: put bituminous coal, coking coal, coke powder, and asphalt into the pulverizer at a weight ratio of 35:20:20:15, and the particle size is required to be 325 mesh and 70% pass;

[0045] (2) Mixing: Mix the ground carbon powder, coal tar, and water in a weight ratio of 80:12:10, and the mixing temperature is 45°C to 50°C;

[0046] (3) Granulation: add the mixture into the mold to make hollow activated carbon raw material, the outer diameter of the hollow activated carbon raw material is 9.0-10.0mm, and the inner diameter is 2-3mm; then the hollow activated carbon raw material is cut into the required length by a cutter as pellets;

[0047] (4) Drying: The granulated material is dried in a dryer at a drying temperature of 95°C~100°C;

[0048] (5) Carbonization: Put the dry material into the converter for carbonization, the temperature is...

Embodiment 3

[0053] A method for producing hollow activated carbon for desulfurization and denitrification, comprising the steps of:

[0054] (1) Grinding: put bituminous coal, coking coal, coke powder, and asphalt into the pulverizer in a weight ratio of 40:25:15:12 for grinding, and the particle size requires 325 mesh and 70% pass;

[0055] (2) Mixing: Mix the ground carbon powder, coal tar, and water in a weight ratio of 80:15:12, and the mixing temperature is 40°C to 45°C;

[0056] (3) Granulation: Add the mixture into the mold to make hollow activated carbon raw materials. The outer diameter of the hollow activated carbon raw material is 9.0-10.0mm, and the inner diameter is 2-3mm; then the hollow activated carbon raw material is cut into the required length by a cutter as pellets;

[0057] (4) Drying: The granulated material is dried in a dryer at a drying temperature of 100°C~110°C;

[0058] (5) Carbonization: Put the dry material into the converter for carbonization, the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com