Low-temperature stone chip-resistant automobile refinishing paint varnish and preparation method thereof

An automobile refinish paint and anti-stone chip technology, which is applied in the field of automobile refinish paint, can solve the problems of unsatisfactory anti-stone chip effects, and achieve excellent stone chip resistance, low VOC, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of low-temperature anti-stone chip automobile refinish paint varnish preferably comprises the following steps:

[0031] (1) Take hydroxyacrylic resin and solvent according to the formula, stir at 600-800rpm for 5-15min, and disperse evenly;

[0032] (2) Add leveling agent, ultraviolet absorber and catalyst in turn under the low-speed stirring condition of 150-300rpm, stir and disperse at high speed at 1000-1500rpm for 30 minutes, and obtain the target product.

Embodiment 1

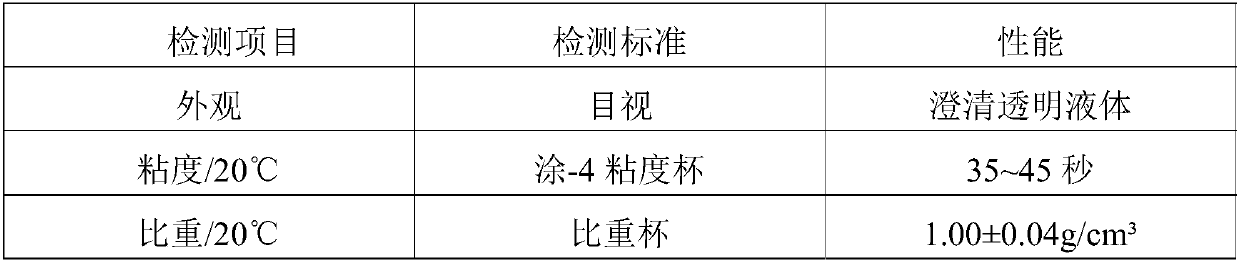

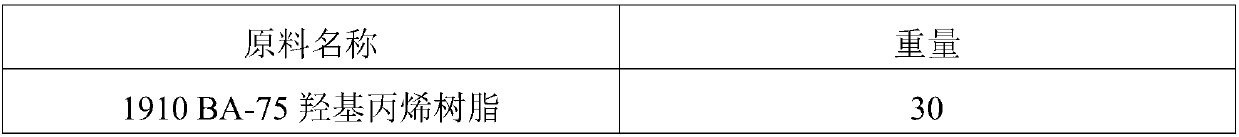

[0034] (1) The formula of anti-stone chip varnish is as follows:

[0035] raw material name

weight

Setalux 1910 BA-75 Hydroxypropylene Resin

30

FS-4660 Hydroxypropylene Resin

35

PMA

7.0

10

13

BYK361N

0.5

BYK301

0.3

TINUVIN234

1.0

DABCO T120

0.2

[0036] (2) Preparation process:

[0037] Add Nupace 1910 BA-75 hydroxypropylene resin, FS-4660 hydroxypropylene resin, PMA, xylene, n-butyl acetate in the formula to the stirring tank, stir at 600-800r / min for 5-15 minutes, then Slowly add BYK361N, BYK301, TINUVIN234, and DABCO T120 in the formula to the above dispersion in sequence. The stirring speed is 1000-1500r / min, stirring for 30min, and filtering to obtain the anti-stone chipping varnish.

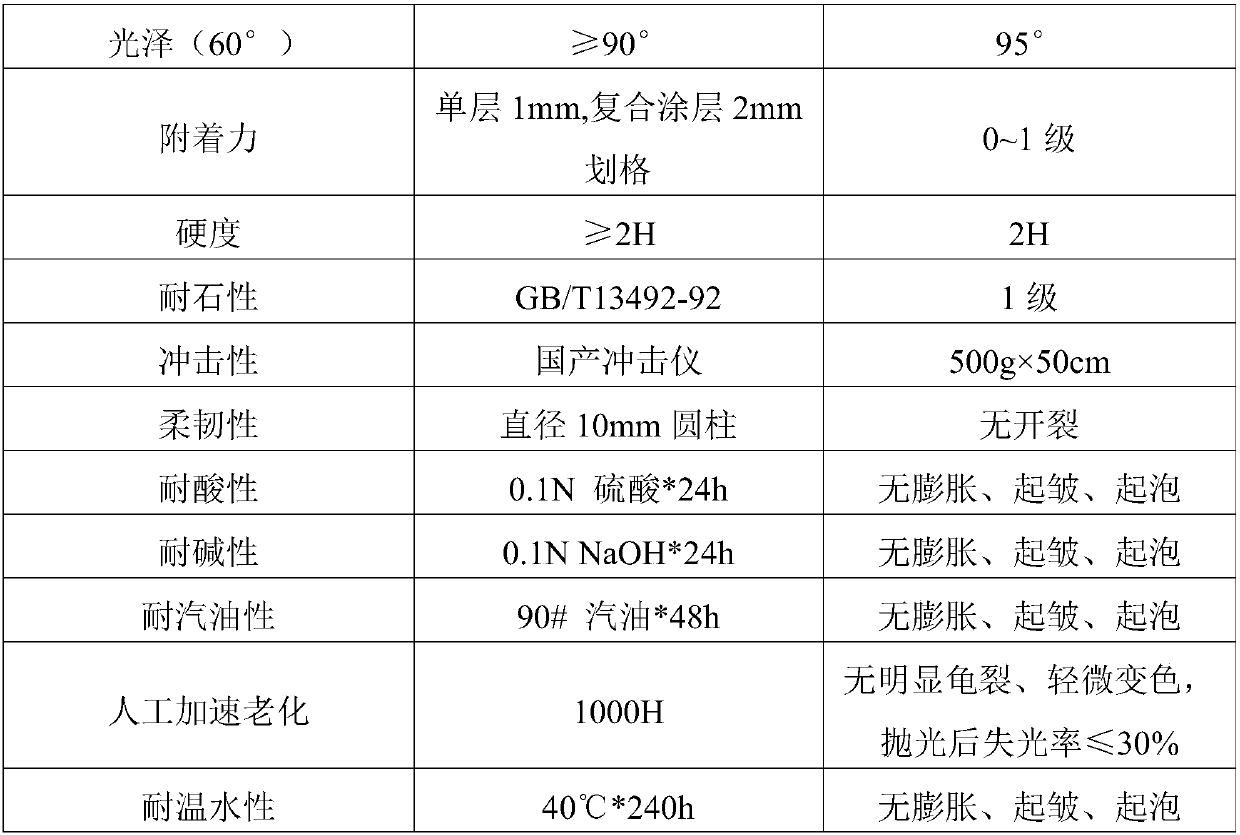

[0038] (3) Construction inspection:

[0039] Add 55 parts of N-3390 and 45 parts of PMA into the stirring tank, stir at 600-800r / min for 25-3 minutes, and fi...

Embodiment 2

[0045] Compared with Example 1, except that the formula of anti-stone chip automotive refinish paint varnish is changed as follows, all the others are the same.

[0046] raw material name

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com