High-strength damping paint

A damping coating and high-strength technology, applied in the field of damping coatings, can solve the problems of high emulsion requirements, poor impact resistance, and low strength, and achieve good flexibility, good salt spray resistance, and good impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

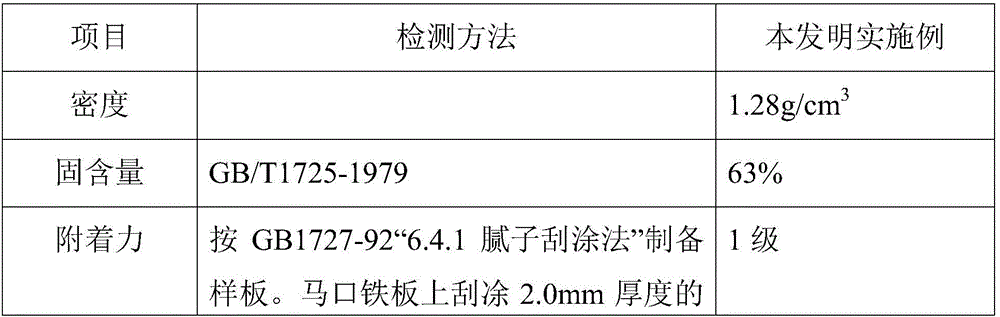

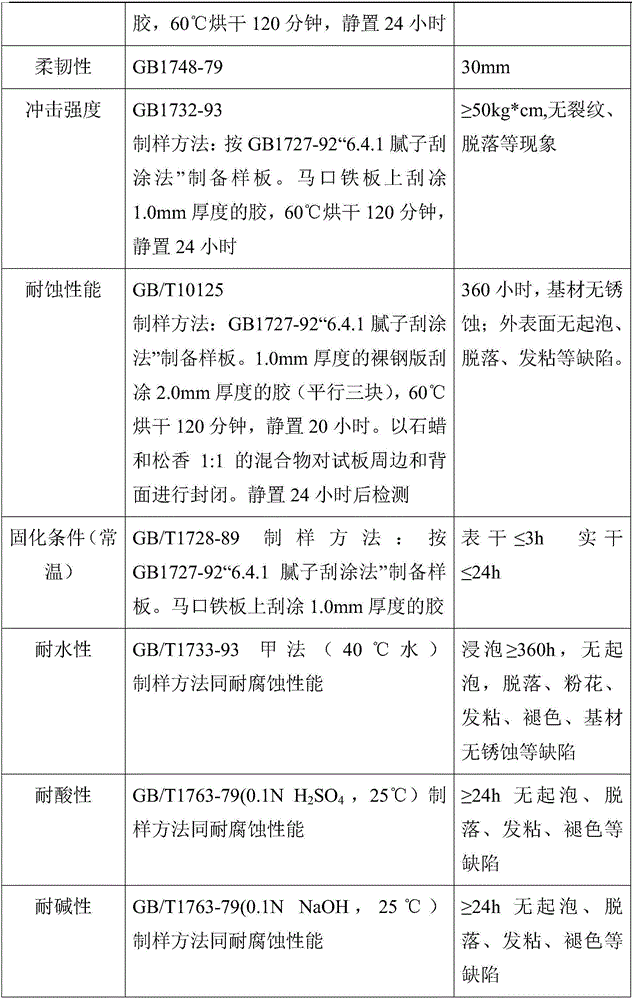

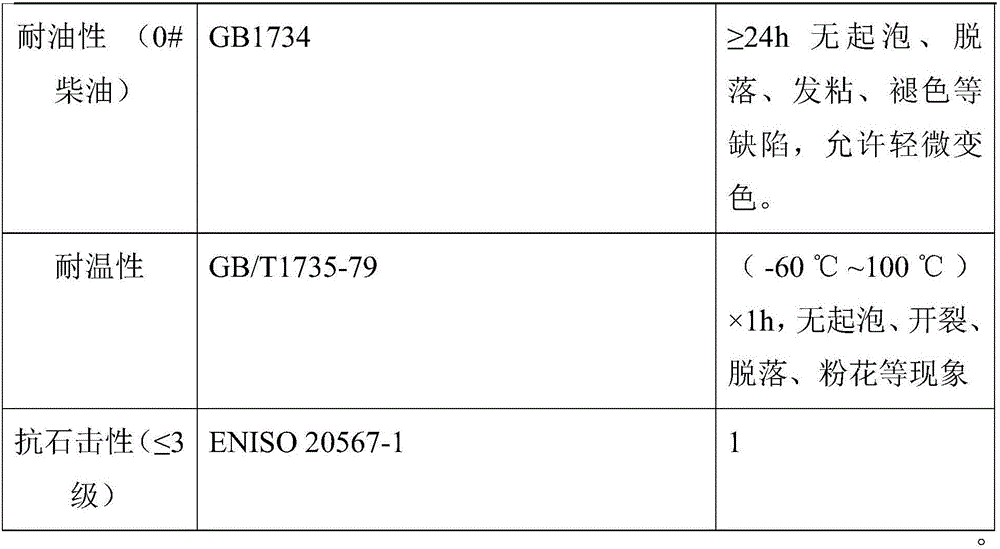

Examples

Embodiment 1

[0024] A high-strength damping paint, calculated in parts by weight, including the following raw materials:

[0025] 150 parts of vinyl acetate-ethylene copolymer emulsion, 150 parts of waterproof emulsion BA-163, 150 parts of pure acrylic emulsion, 100 parts of zinc borate, 100 parts of aluminum phosphate, 5 parts of silicone defoamer, 75 parts of mica powder, 25 parts of floating beads Parts, 50 parts of talc powder, 100 parts of silica powder, 25 parts of preservative, 100 parts of ultra-phosphor zinc white and 5 parts of black paste.

[0026] Among them, the solid content of the pure acrylic emulsion is 30±2%, the pH is 7 to 7.5, the glass transition temperature is -5°C, the minimum film forming temperature is 0°C, and the viscosity is less than 20cps; low solid content and low viscosity can increase the amount of fillers. cut costs.

Embodiment 2

[0028] A high-strength damping paint, calculated in parts by weight, including the following raw materials:

[0029] 145 parts of vinyl acetate-ethylene copolymer emulsion, 145 parts of waterproof emulsion BA-163, 155 parts of pure acrylic emulsion, 100 parts of zinc borate, 95 parts of aluminum hydroxide, 4 parts of silicone defoamer, 70 parts of mica powder, floating beads 23 parts, 45 parts talc powder, 95 parts silica powder, 23 parts preservative, 95 parts super phosphorous zinc white and 4 parts black paste.

[0030] Among them, the solid content of the pure acrylic emulsion is 30±2%, the pH is 7 to 7.5, the glass transition temperature is -5°C, the minimum film forming temperature is 0°C, and the viscosity is less than 20cps; low solid content and low viscosity can increase the amount of fillers. cut costs.

Embodiment 3

[0032] A high-strength damping paint, calculated in parts by weight, including the following raw materials:

[0033] 155 parts of vinyl acetate-ethylene copolymer emulsion, 155 parts of waterproof emulsion BA-163, 145 parts of pure acrylic emulsion, 100 parts of magnesium hydroxide, 105 parts of aluminum hydroxide, 6 parts of acrylic defoamer, 80 parts of mica powder, floating beads 27 parts, 55 parts of talc powder, 105 parts of silica powder, 27 parts of preservatives, 105 parts of ultra-phosphor zinc white and 6 parts of black paste.

[0034] Among them, the solid content of the pure acrylic emulsion is 30±2%, the pH is 7 to 7.5, the glass transition temperature is -5°C, the minimum film forming temperature is 0°C, and the viscosity is less than 20cps; low solid content and low viscosity can increase the amount of fillers. cut costs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com