Stone-crash-resistant automobile corrosion-resistant wax and preparation method thereof

An anti-corrosion wax and anti-stone impact technology, applied in the direction of anti-corrosion coatings, coatings, metal material coating processes, etc., can solve the problems of the anti-corrosion performance to be improved, unsuitable for automatic spraying, poor anti-stone impact performance of anti-corrosion wax, etc. Good long-term corrosion resistance, beneficial to the environment and safety, good water resistance and anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

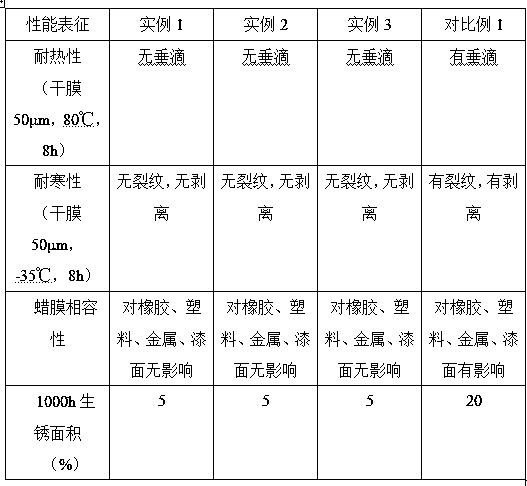

Examples

Embodiment Construction

[0022] Take 5-10g beeswax, 5-10g oxidized paraffin, 5-10g water-based alkyd resin, 5-10g petroleum resin, put them into a grinder and grind for 30-40min to obtain compound paraffin, take 8-16g phytic acid, 2 Put ~4g of tannic acid into a mixing tank, stir at 300~400rmin for 20~30min to obtain a composite antirust agent, take 2~3g of nanographene, add it to 200~300g of absolute ethanol, and disperse it with 300W ultrasonic wave for 15 ~20min, then add 6~9g oleic acid, heat to 60~80℃, stir at 300~400r / min for 2~3h, cool to room temperature and filter the filter residue, wash the filter residue 2~3 times with absolute ethanol Transfer the filter residue into a drying oven and dry at 120-150°C for 2-3 hours to obtain modified nano-graphene. Put 20-40g of composite paraffin into the reaction kettle, heat it to 70-120°C and heat it at 200-300r / min Stir for 20-30 minutes, then add 10-20g composite anti-rust agent, 1-2g wetting and dispersing agent, and 2-4g emulsifier in order to dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com