Damping paint for automotive chassis armoring

A technology for damping coatings and automobile chassis, applied in the field of damping coatings, can solve the problems of poor aging resistance, flammability of asphalt materials, easy brittleness, hardening and peeling off of asphalt paint films, and achieves the effect of good stone-strike resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

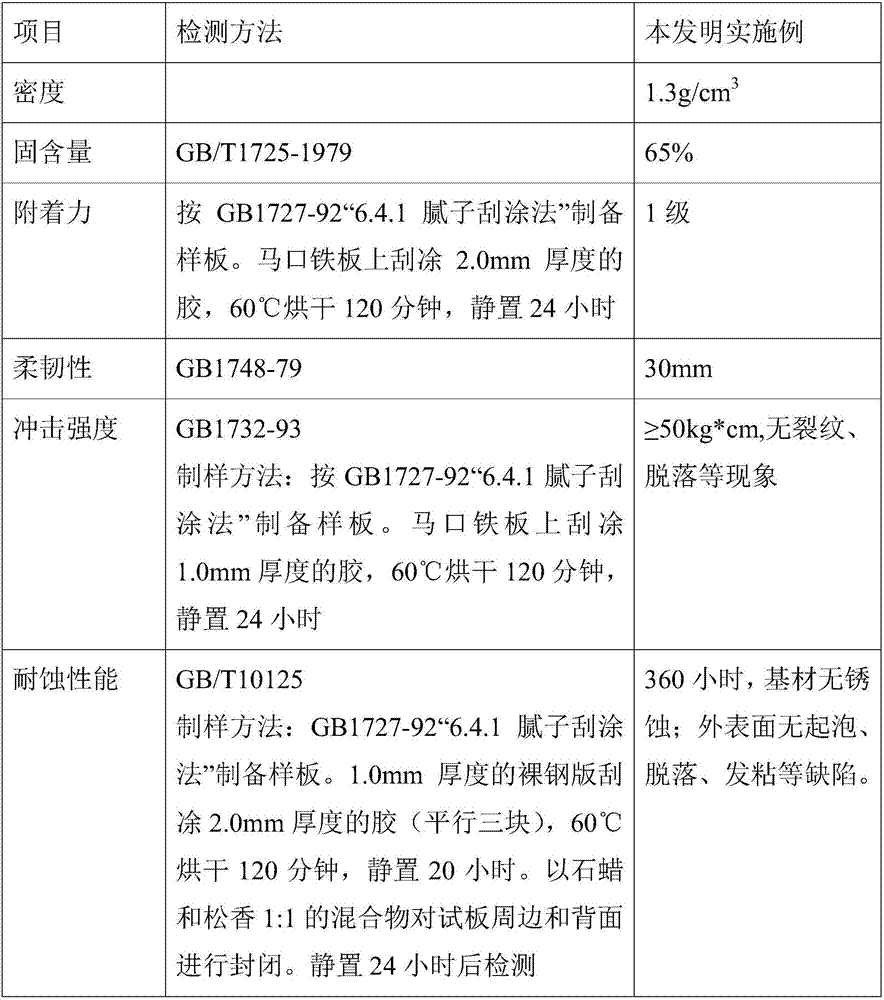

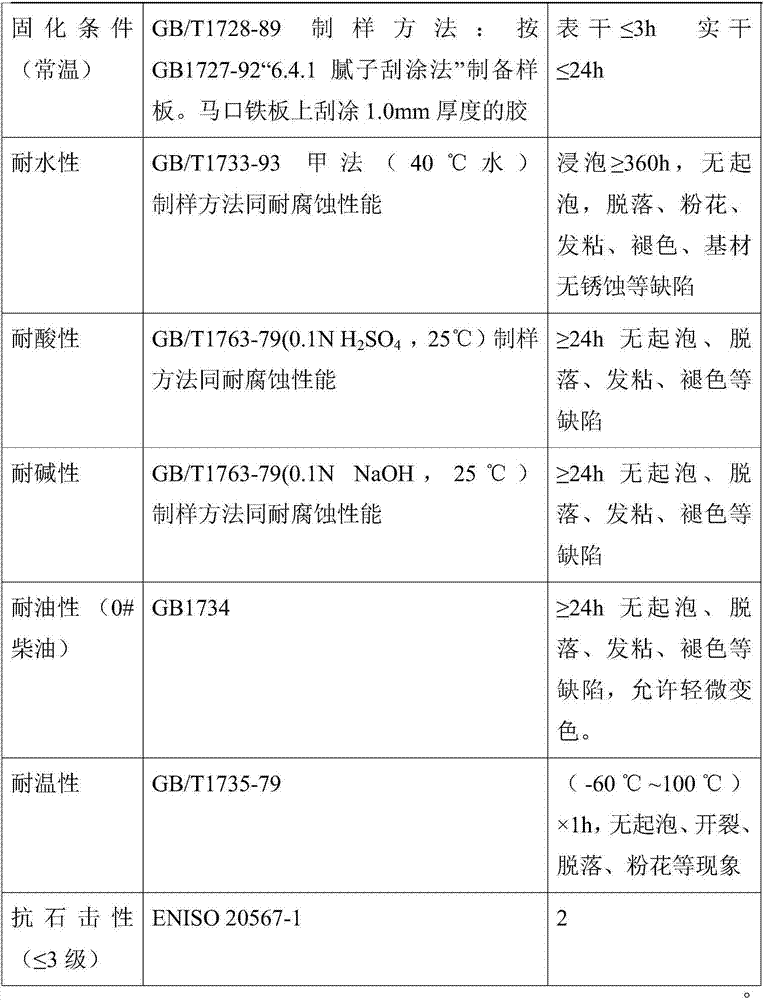

Examples

Embodiment 1

[0034] A damping coating for automobile chassis armor, comprising the following raw materials:

[0035] 150 parts of acrylic waterproof emulsion, 50 parts of antirust emulsion, 100 parts of plasticized acrylic emulsion, 150 parts of pure acrylic emulsion, 15 parts of propylene glycol phenyl ether, 100 parts of mica powder, 25 parts of floating beads, 75 parts of talc powder and 300 parts of silica powder 25 parts of ammonium octamolybdate, 25 parts of preservative, 5 parts of black pulp and 2 parts of alkaline silica sol.

[0036] Wherein, the acrylic waterproof emulsion is German BASF waterproof emulsion S 400F.

[0037] The pure acrylic emulsion has a solid content of 30±2%, a pH of 7-7.5, a glass transition temperature of -5°C, a minimum film-forming temperature of 0°C, and a viscosity of less than 20cps. Low solid content and low viscosity can increase the amount of fillers and reduce costs.

[0038] The anti-rust emulsion is DL-1065 anti-rust emulsion produced by Beijin...

Embodiment 2

[0047] A damping coating for automobile chassis armor, comprising the following raw materials:

[0048] 145 parts of acrylic waterproof emulsion, 45 parts of antirust emulsion, 105 parts of plasticized acrylic emulsion, 145 parts of pure acrylic emulsion, 13 parts of alcohol ester twelve, 95 parts of mica powder, 23 parts of floating beads, 70 parts of talc powder and silica powder 290 parts, 27 parts of magnesium hydroxide, 23 parts of preservatives, 4 parts of black pulp and 1.5 parts of alkaline silica sol.

[0049] Wherein, the acrylic waterproof emulsion is German BASF waterproof emulsion S 400F.

[0050] The anti-rust emulsion is DL-1065 anti-rust emulsion produced by Beijing Donglian Chemical Co., Ltd. Its solid content is 41±1%, pH is 7-7.5, glass transition temperature is 20°C, minimum film-forming temperature is 30°C, and viscosity is less than 20cps , with high gloss, high hardness, good leveling and solvent resistance, excellent adhesion to substrates, high gloss,...

Embodiment 3

[0061] A damping coating for automobile chassis armor, comprising the following raw materials:

[0062] 155 parts of acrylic waterproof emulsion, 55 parts of antirust emulsion, 95 parts of plasticized acrylic emulsion, 155 parts of pure acrylic emulsion, 17 parts of alcohol ester twelve, 105 parts of mica powder, 27 parts of floating beads, 80 parts of talc powder and silica powder 310 parts, 23 parts of magnesium hydroxide, 27 parts of preservatives, 6 parts of black pulp and 2.5 parts of alkaline silica sol.

[0063] Wherein, the acrylic waterproof emulsion is German BASF waterproof emulsion S 400F.

[0064] The pure acrylic emulsion has a solid content of 30±2%, a pH of 7-7.5, a glass transition temperature of -5°C, a minimum film-forming temperature of 0°C, and a viscosity of less than 20cps. Low solid content and low viscosity can increase the amount of fillers and reduce costs.

[0065] The anti-rust emulsion is DL-1065 anti-rust emulsion produced by Beijing Donglian C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com