Aqueous stone-chip-resistant polyurethane dispersion body and preparation method thereof

A technology of polyurethane dispersion and anti-stone impact, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of no correlation and different technical fields, achieve simple lines, low VOC content, and realize large-scale industrial production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

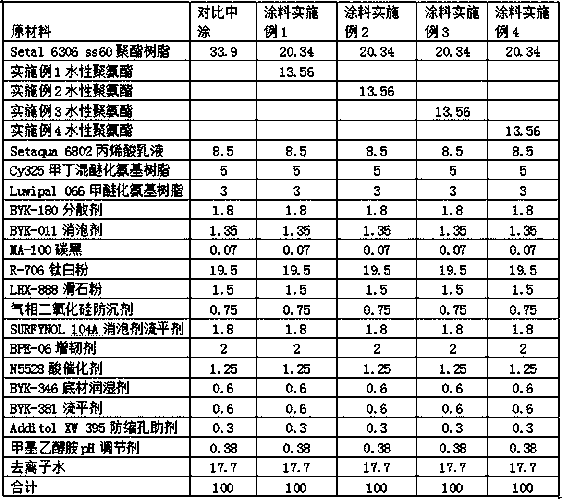

Examples

Embodiment 1

[0047] In the reaction kettle, 92g of polycarbonate diol (Mn=3000) compound was dewatered at 105°C for 2 hours under negative pressure of -0.09MPa, and the water content was confirmed to be 0.02%; then 28g of isophorone diisocyanate Add, pre-react at 70°C for 30 minutes, then add 0.08g of catalyst, and react for another 2 hours to reach the set NCO value of 7.94-7.74%; then add 7.2g of dimethylol propionic acid and continue the reaction at 80°C 4 hours to reach the set NCO value of 5.83-5.53%; then add 20g of hexanediol and continue the reaction at 85°C for 0.5 hours to reach the set NCO value of 1.80-1.55%; then dissolve 7.2g of trimethylamine in N - Add 40g of methylpyrrolidone into the reaction kettle, and neutralize at 50°C for 1 hour; then add 176.72g of deionized water in the formula amount, and carry out phase inversion emulsification under high-speed dispersion conditions; finally add chain extender to the emulsion 4.8 g of butylenediamine, continued emulsification and...

Embodiment 2

[0050] Put 60g of polycarbonate diol (Mn=1000) compound in the reaction kettle under the negative pressure condition of -0.07MPa, remove water at 100°C for 3 hours, and confirm that the water content is 0.025%; then hydrogenated diphenylmethane diisocyanate Add 40g, pre-react at 90°C for 30min, then add 0.12g of catalyst, and react for another 0.5h to reach the set NCO value of 11.01-10.91%; then add 14g of dimethylol butyric acid and continue the reaction at 95°C 2 hours to reach the set NCO value of 6.39-6.09%; then add 12g of propylene glycol and continue the reaction at 80°C for 1 hour to reach the set NCO value of 1.92-1.72%; then dissolve 13.6g of triethylamine in N- Add 24g of methylpyrrolidone to the reaction kettle, and neutralize at 60°C for 45 minutes; then add 214.28g of deionized water in the formula amount, and carry out phase inversion emulsification under high-speed dispersion conditions; finally add the chain extender hexadiene to the emulsion amine 6g, contin...

Embodiment 3

[0053] In the reaction kettle, 76g of polycaprolactone diol (Mn=2000) compound was dewatered at 103°C for 2 hours under negative pressure of -0.07MPa, and the water content was 0.03%; then hydrogenated diphenylmethane diisocyanate Add 56g, pre-react at 80°C for 30 minutes, then add 0.2g of catalyst, and react for another hour to reach the set NCO value of 12.11-11.81%; then add 11.6g of dimethylol butyric acid, continue at 90°C React for 3 hours to reach the set NCO value of 6.59-6.29%; then add 4g of butanediol and continue the reaction at 95°C for 0.5 hours to reach the set NCO value of 2.27-2.07%; then add 11.6g of triethylenediamine first Dissolved in 32g of N-methylpyrrolidone, then added to the reaction kettle, and neutralized at 65°C for 0.5 hours; then added 185.4g of deionized water in the formula amount, and carried out phase inversion emulsification under high-speed dispersion conditions; finally added to the emulsion The chain extender butyldiamine was 3.2g, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com