Non-gel double-faced flexible copper clad laminate production equipment

A technology for flexible copper clad laminates and production equipment, which is applied in the field of adhesive-free double-sided flexible copper clad laminate production equipment, can solve problems such as low work efficiency, uneven vacuum degree, and large energy consumption, so as to improve work efficiency and vacuum degree Uniform and improved pumping speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

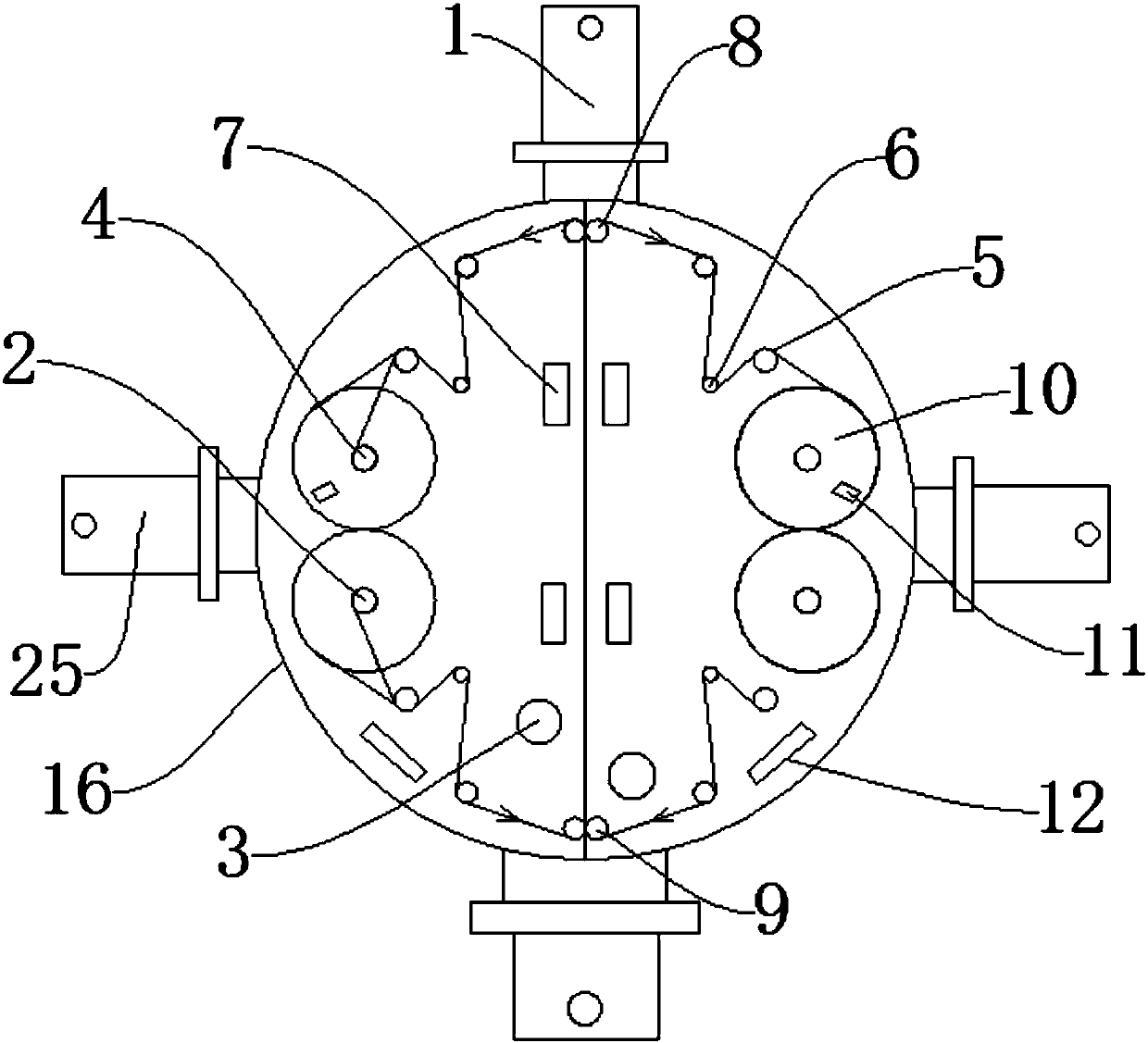

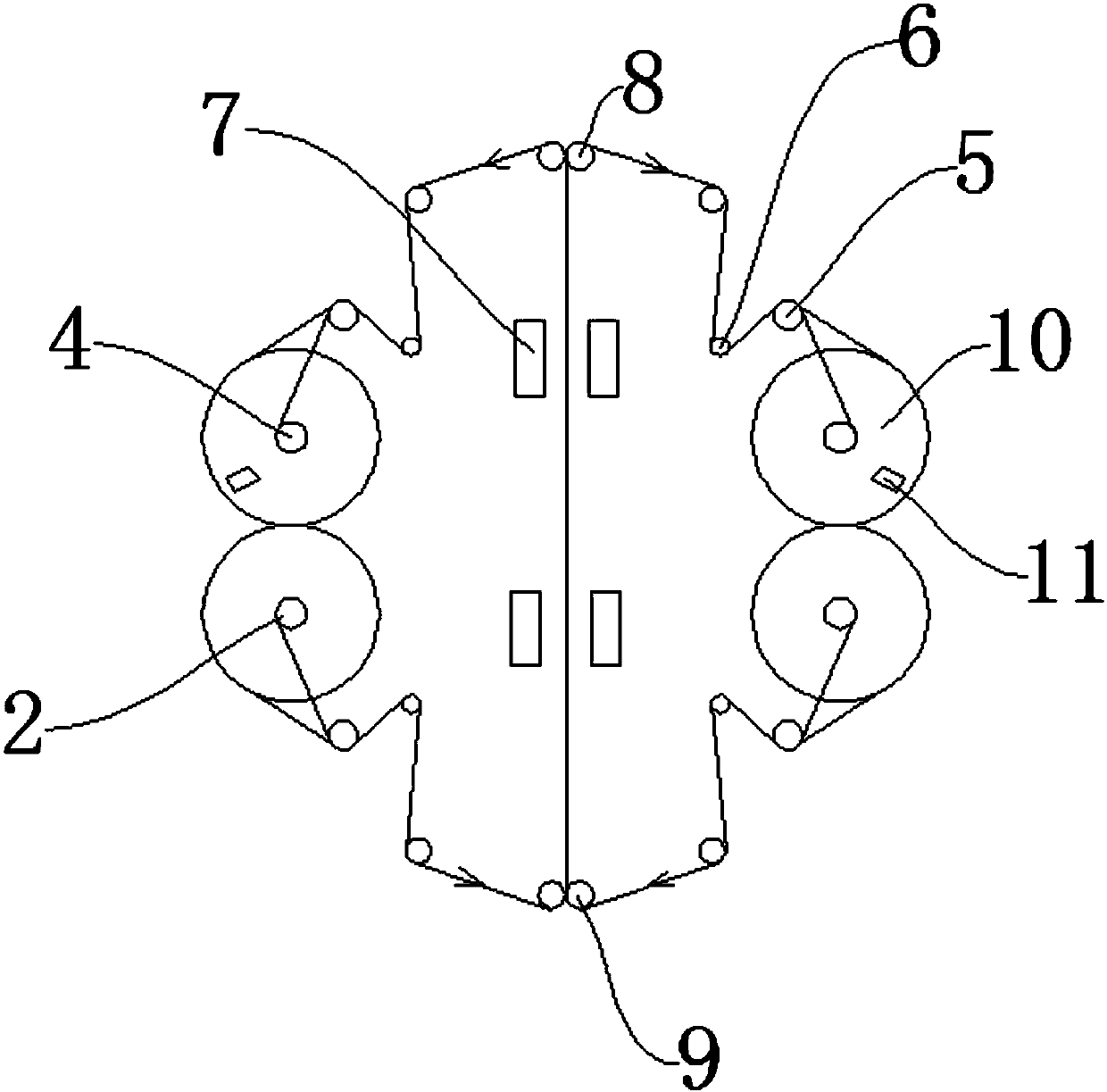

[0038] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

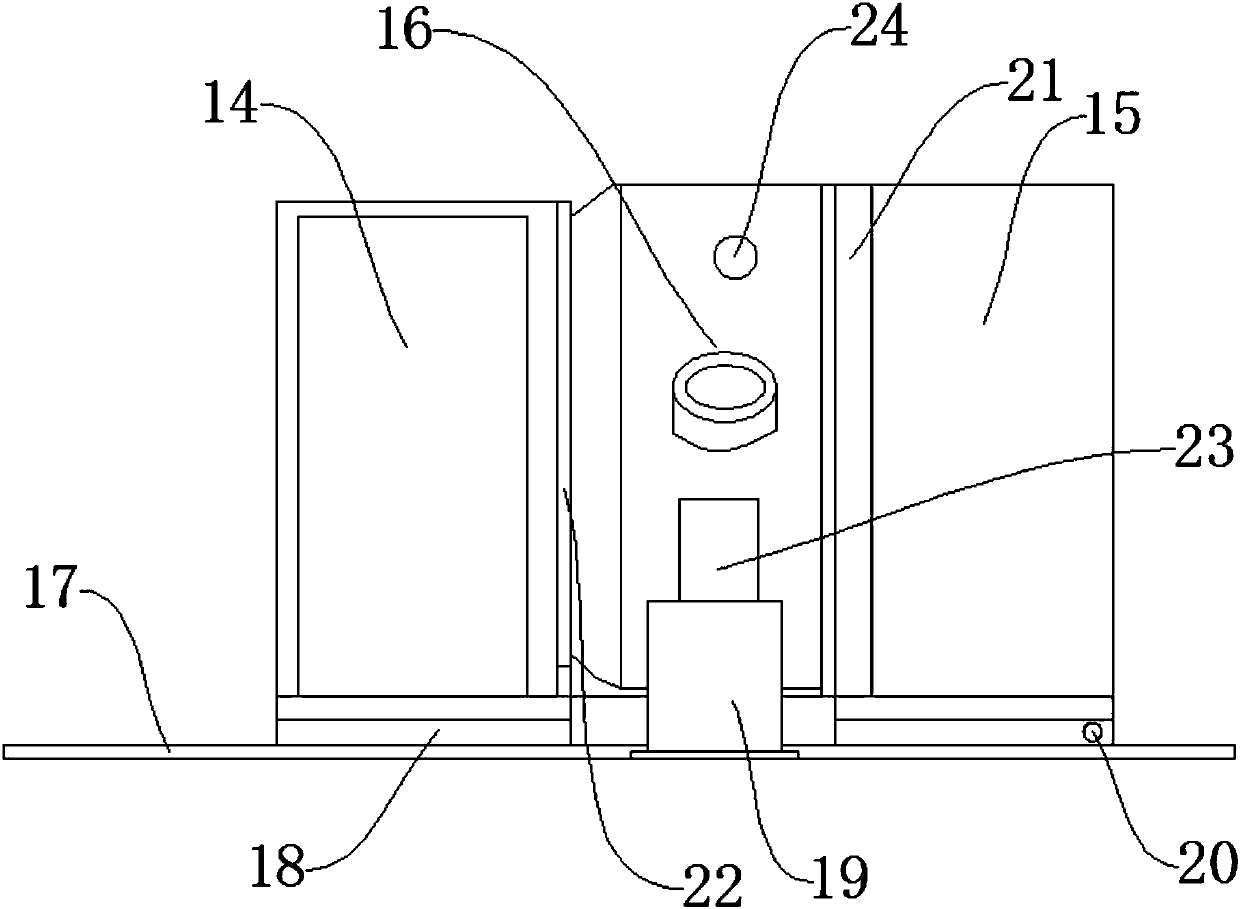

[0039] Such as Figure 1-Figure 4As shown, an adhesive-free double-sided flexible copper-clad laminate production equipment includes a vacuum chamber 16 and a rewinding and unwinding system 15. A target cart 14 is arranged on one side of the vacuum chamber 16, and a target cart 14 is mounted on the target cart 14. A target 7 is provided, a second seal 22 is provided between the target cart 14 and the vacuum chamber 16, and a rear flange is provided on the side of the vacuum chamber 16 close to the target cart 14 13. The other side of the vacuum chamber 16 is provided with the winding and unwinding system 15, and a first sealing member 21 is provided between the winding and unwinding system 15 and the vacuum chamber 16, and the winding and unwinding system 15 A sliding seat 18 is provided under the system 15 and the target vehicle 14, a drive motor 20 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com