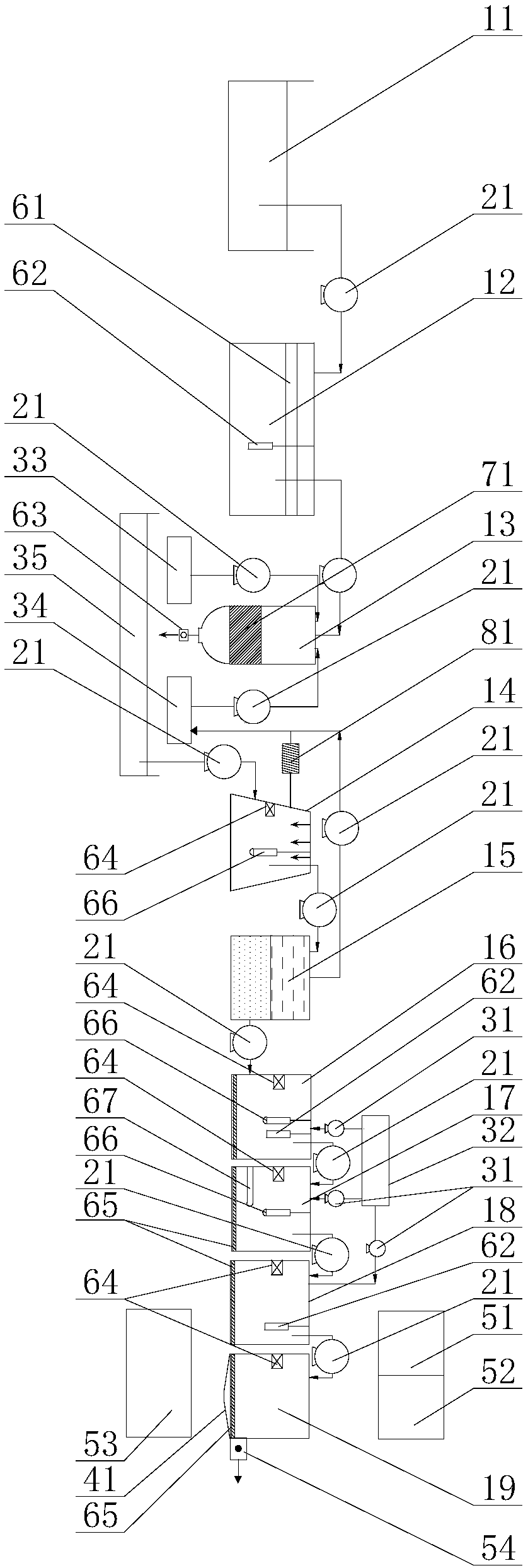

Purification device and treatment method for PPCPs in drinking water source

A technology of purification device and water source, applied in multi-stage water treatment, water/sewage treatment, water treatment parameter control, etc., can solve problems such as difficulty in directional removal of PPCPs, re-entry of PPCPs into the environment, and limited treatment technology for PPCPs, etc. The effect of treating water sample volume, high practical value, and improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

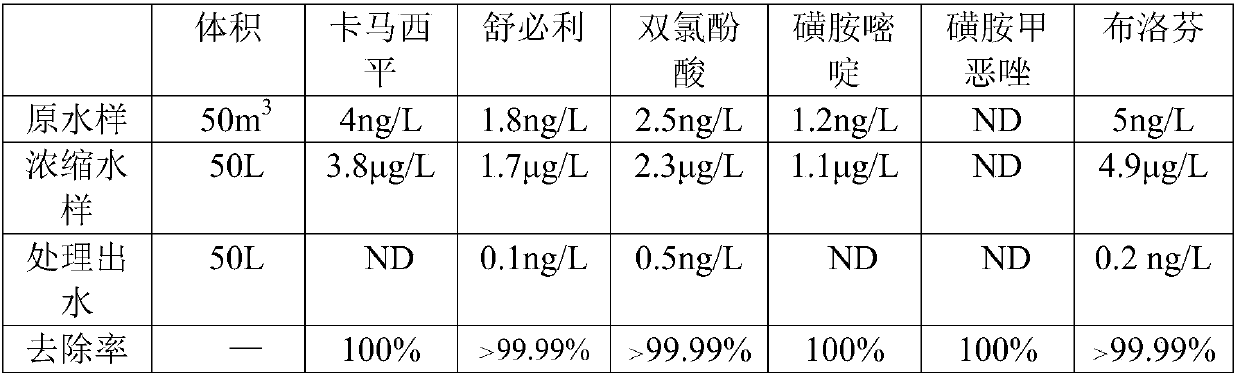

Embodiment 1

[0067] The water sample in a certain reservoir A is treated by the present invention.

[0068] Continuous water intake 50m 3 . Pump the water sample into the first pretreatment tank, filter out the particulate matter, adjust the pH to 7, and the volume of the solid phase extraction device is 5m 3 , the amount of adsorbent used is 100kg, after the solid-phase extraction column packing is pretreated by 2 times the column volume of methanol and pure water, the water sample is pumped into the solid-phase extraction device with a flow rate of 10m 3 / h, the solid-phase extraction column packing completes the adsorption of PPCPs. Then, 1 times the column volume of methanol was used to elute the packing of the solid-phase extraction column, and the eluent then entered the automatic nitrogen blowing device, which was concentrated by nitrogen blowing to reduce the volume of the water sample, and condensed to recover methanol, which was reused in the solid-phase extraction process. Th...

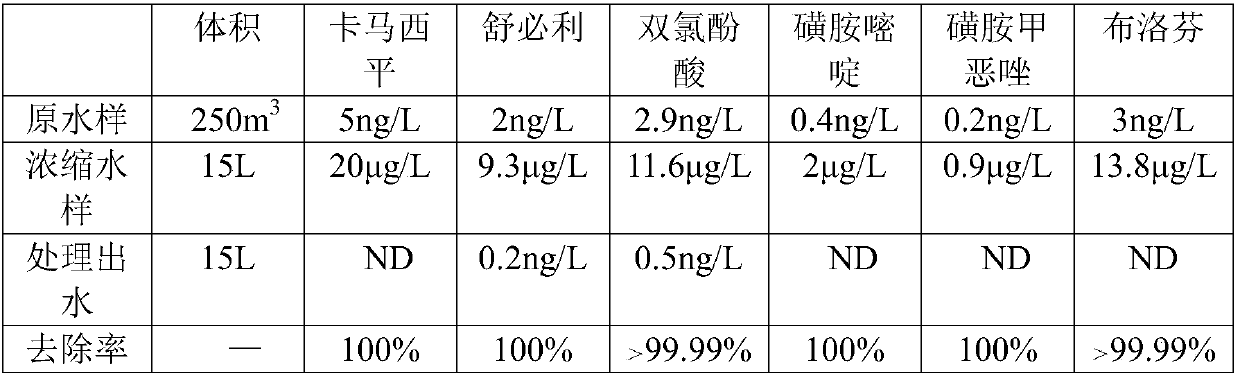

Embodiment 2

[0071] Embodiment two: adopt the present invention to process the water sample in certain reservoir B:

[0072] Continuous water intake 250m 3 . Pump the water sample into the first pretreatment tank, filter out the particulate matter, adjust the pH to 5, and the volume of the solid phase extraction device is 5m 3 , the amount of solid phase extraction column filler used is 150kg. After the column is pretreated by 2 times the column volume of methanol and pure water, the water sample is pumped into the solid phase extraction device with a flow rate of 15m 3 / h, the solid-phase extraction column packing completes the adsorption of PPCPs. Then use 1 times the column volume of methanol to elute the solid phase extraction column packing, and then the eluent enters the automatic nitrogen blowing device, nitrogen blowing and concentration reduces the processing volume, and condenses to recover methanol, which is reused in the solid phase extraction process. The concentrated liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com