A kind of fluorosilicone oil and preparation method thereof

A technology of fluorosilicone oil and fluorosilicone oil, which is applied in the field of new fluorosilicone oil and its preparation, can solve the problems of poor quality, zero, and single variety of fluorosilicone oil, and achieve fast reaction speed, simple equipment and process, and product function-based The effect of high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

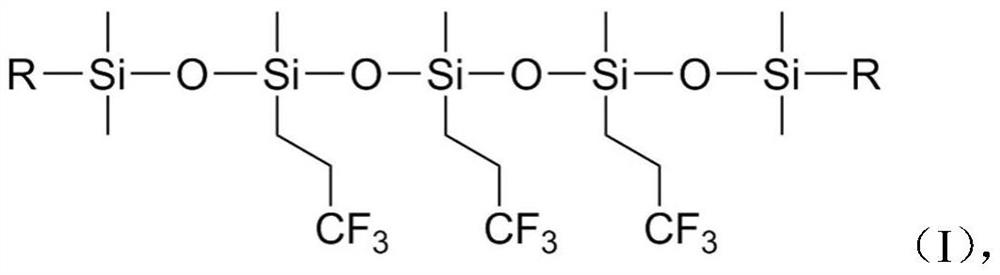

[0030] Add 134g MM H and 234g D 3 F, then put it in an oil bath at 20°C, add 28g of strong acidic cation exchange resin, stir and react for 4h, GC detection D 3 F conversion was 92.4%. Cool to room temperature with stirring, remove the resin by filtration, distill under reduced pressure and collect the product under the condition of 109~110℃ / 800Pa to obtain colorless and transparent hydrogen-terminated fluorosilicone oil 1,1,3,5,7,9,9- Heptamethyl-3,5,7-tris(3,3,3-trifluoropropyl)pentasiloxane, yield 87.3%. The density at 25°C is 1.11 and the refractive index is 1.373.

Embodiment 2

[0032] Add 134g MM H and 234g D 3 F, then put it in an oil bath at 30°C, add 28g of strong acidic cation exchange resin, stir and react for 2h, GC detection D 3 F conversion was 93.8%. Cool to room temperature with stirring, remove the resin by filtration, distill under reduced pressure and collect the product under the condition of 109~110℃ / 800Pa to obtain colorless and transparent hydrogen-terminated fluorosilicone oil 1,1,3,5,7,9,9- Heptamethyl-3,5,7-tris(3,3,3-trifluoropropyl)pentasiloxane, yield 90.5%.

Embodiment 3

[0034] Add 134g MM H and 234g D 3 F, then put it in an oil bath at 40°C, add 28g of strong acidic cation exchange resin, stir and react for 1h, GC detection D 3 F conversion was 91.3%. Cool to room temperature with stirring, remove the resin by filtration, distill under reduced pressure and collect the product under the condition of 109~110℃ / 800Pa to obtain colorless and transparent hydrogen-terminated fluorosilicone oil 1,1,3,5,7,9,9- Heptamethyl-3,5,7-tris(3,3,3-trifluoropropyl)pentasiloxane, yield 86.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com