Circulating fluidized bed boiler explosion protection system

A technology of circulating fluidized bed and explosion-proof system, which is applied in the direction of fluidized bed combustion equipment, burning fuel in melting state, combustion type, etc., and can solve problems such as single arrangement of furnace explosion-proof devices, inability to set and adjust take-off pressure, etc. To achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be clearly and completely described below through specific embodiments.

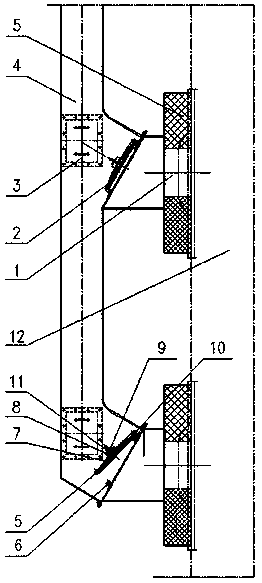

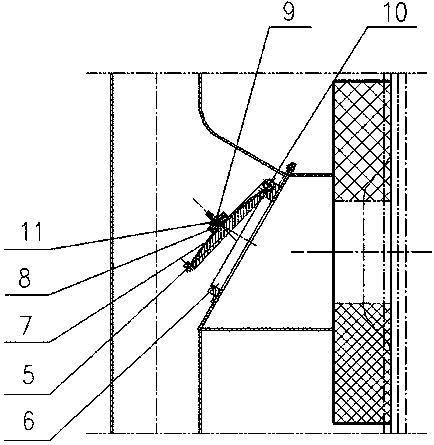

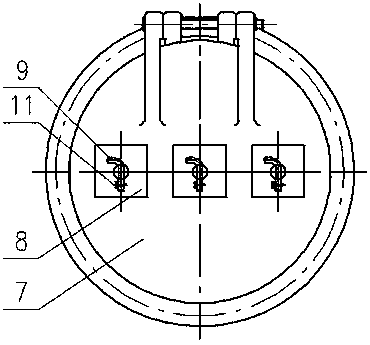

[0018] Such as figure 1 Shown is the explosion-proof system of the circulating fluidized bed boiler of the present invention, which includes a casing 1 arranged on the walls on both sides of the furnace, an explosion-proof device 2, an inspection door 3 and a flue discharge 4, and the casing 1 is welded on the furnace On the side wall of the casing 1, the inside of the casing 1 is filled with castable material 5, and a circular channel with a diameter of D is left in the middle; the explosion-proof device 2 is arranged obliquely at an angle of θ with the vertical direction, including a door seat 6, an explosion-proof door cover 7. Counterweight 8, clip 9, pin shaft 10, cotter pin 11 and castable 5; the door seat 6 is welded on the casing 1, the explosion-proof door cover 7 is lined with castable 5, and the explosion-proof door cover 7 The uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com