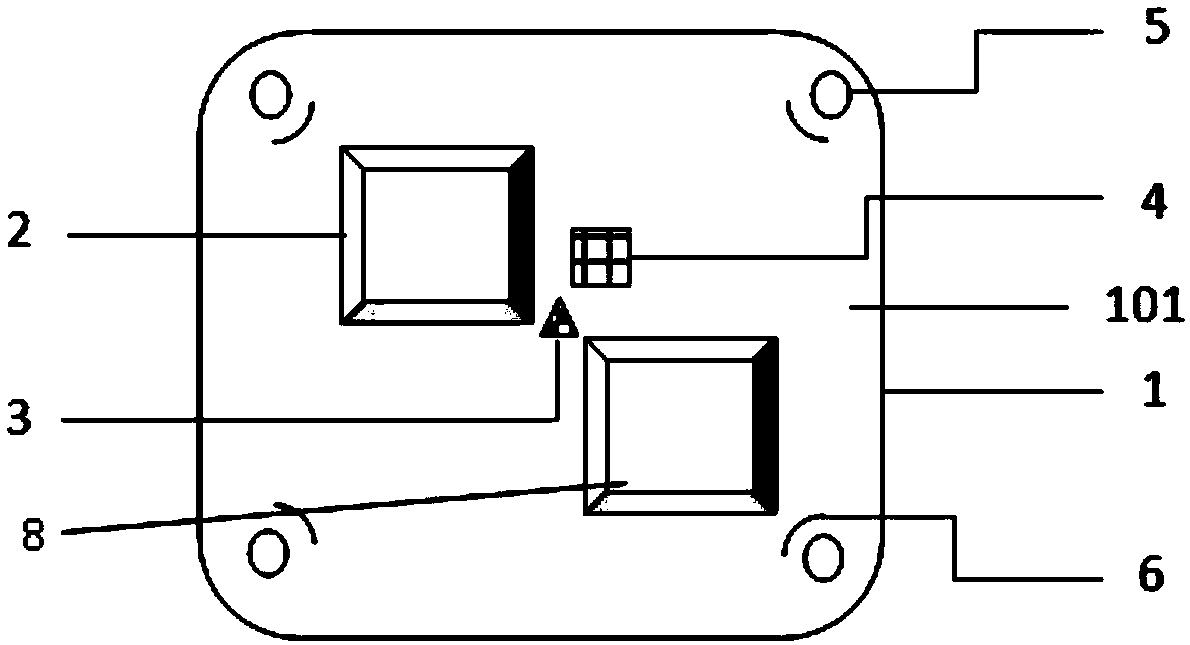

Real-time monitoring device and method for multifunctional corrosion in oil-water separation tank

An oil-water separation tank, real-time monitoring technology, applied in measurement devices, analysis materials, analysis of gas mixtures, etc., can solve the problem of heavy workload, failure of separation tank, and inability to reflect the thinning of the inner wall of the separation tank in real time, medium corrosive sacrificial anode block The protection effect size and other issues can prevent premature failure and reduce the burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

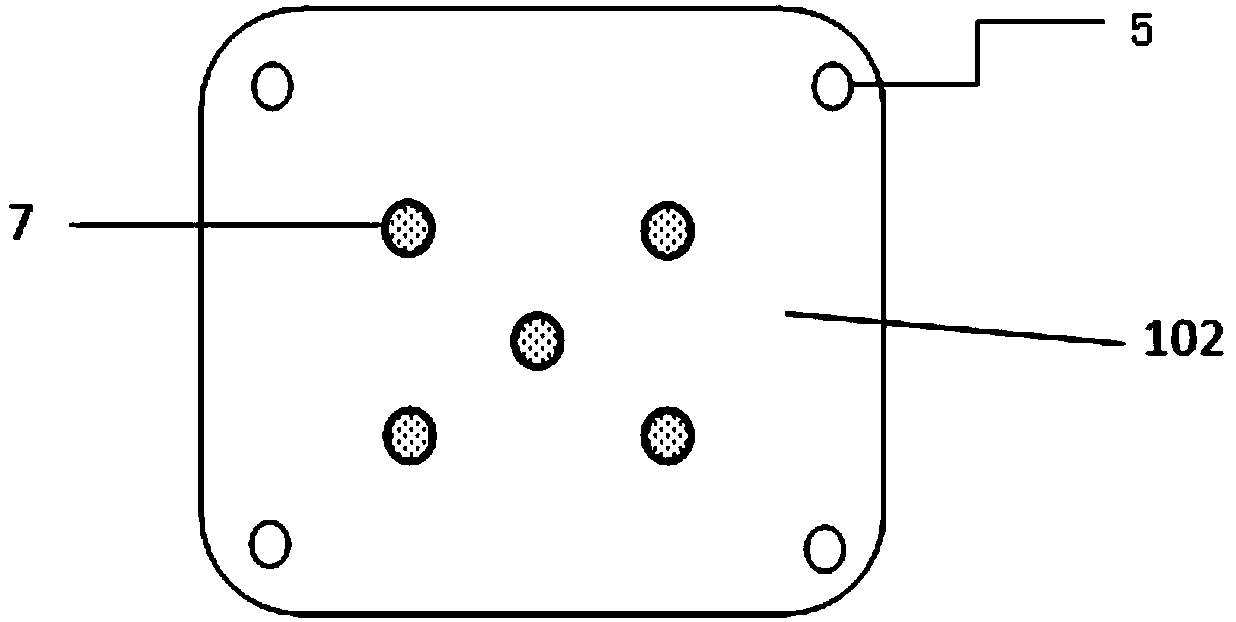

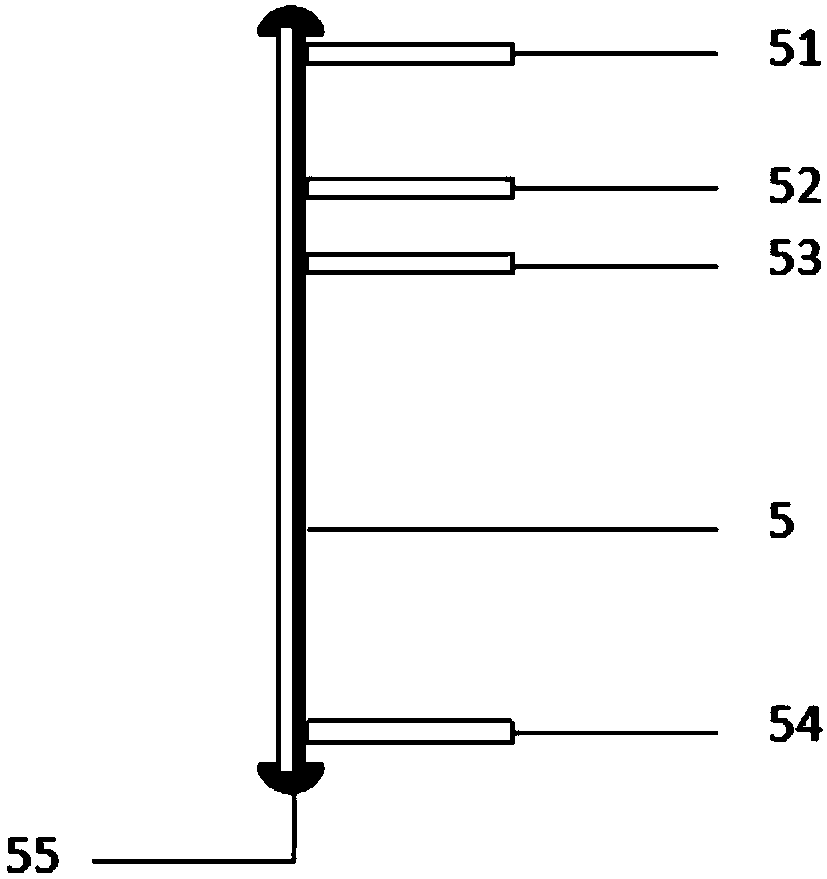

Method used

Image

Examples

specific example 1

[0029] Specific example 1: The pH probe is used to monitor the pH value of the medium in the oil-water separation tank, and the wireless transmitter converts the monitoring results into electrical signals and transmits them. Convert, and transmit to the computer for storage through the data line, open the relevant software on the computer, click the "acidity" selection card item, or query the historical records or directly display the dynamics of the pH value of the solution in the oil-water separation tank at a certain temperature on the computer screen change graph. If the pH value displayed on the screen is low, it means that the medium in the oil-water separation tank is relatively corrosive, and the corrosion rate of the monitored bare steel sample is high or the coating sample may change significantly, so the monitoring cycle needs to be shortened ; If the pH value is very low, it is necessary to stop the transportation and monitor the dissolution degree of the sacrifici...

specific example 2

[0030] Specific example 2: If the computer-related software "Cl - Concentration" option card displayed under the Cl - The concentration data fluctuates relatively large, indicating that through Cl - The change of incoming liquid of each gathering and transportation pipeline monitored by the probe, necessary measures shall be taken to avoid severe corrosion of the oil-water separation tank due to insufficient pretreatment of the produced liquid of individual wells and shorten its service life, or It has a strong fouling property, which leads to serious fouling of sediment components on the surface of the sacrificial anode block, thereby affecting the output of the protective current of the sacrificial anode block.

specific example 3

[0031] Specific example 3: If the voltage / output current of the sacrificial anode block at the bottom of the oil-water separation tank is unstable or high / low, the injection should be stopped in time and merged into the tank for inspection, Or replace the sacrificial anode block in time to ensure the protective effect of the sacrificial anode block on the tank body of the oil-water separation tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com