a tio 2 Sols and catalytic cracking catalysts and methods for their preparation

A technology of sol and acid solution, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, catalytic cracking, etc. It can solve the problems of poor bonding performance and difficult catalytic cracking catalyst, etc., to achieve Effects of increasing catalyst stability, increasing specific surface area, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

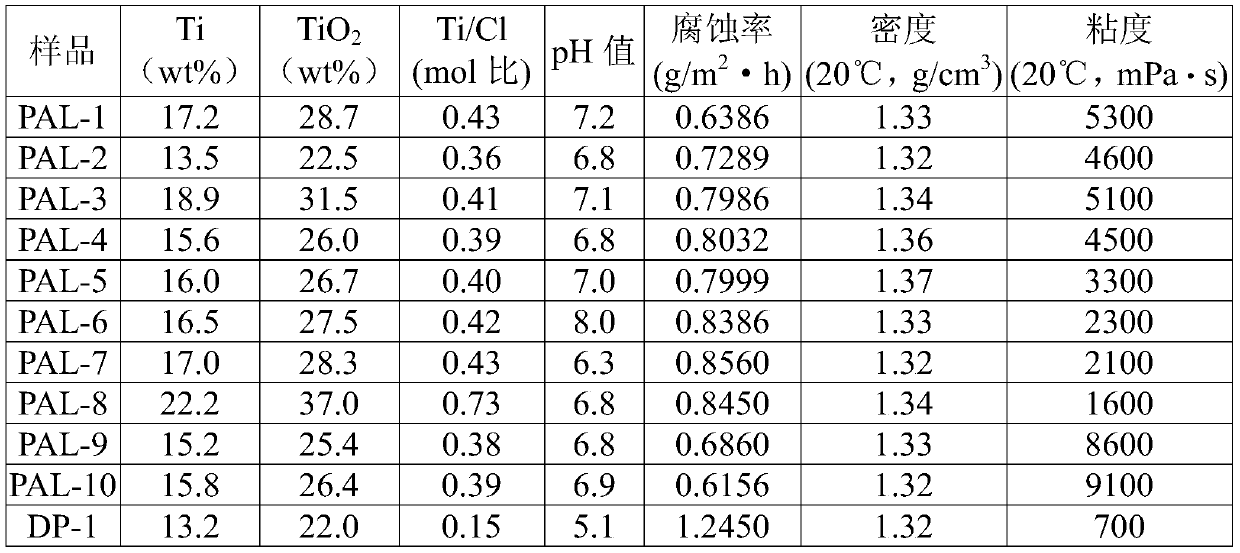

[0039] According to a second aspect of the present invention, there is also provided a TiO 2 A method for preparing a sol, the preparation method comprising the following steps: S1, performing a first contact reaction with a first titanium source and an alkali solution to obtain a first mixture with a pH value ≥ 8; S2, combining a second titanium source with an acid solution containing HCl Carrying out a second contact reaction, the molar ratio of the acid solution in terms of hydrogen ions to the second titanium source in terms of titanium is 0.1-0.3:1 to obtain a second mixture; S3, combining the first mixture with the second The mixture is subjected to a third contact reaction at a molar ratio of the first titanium source to the second titanium source of 1:0.8-1 to obtain a third mixture; and an optional rare earth-containing compound and / or Phosphorus-containing compounds, and optional decationized water and / or deionized water, to obtain a titanium chloride molar ratio of ...

Embodiment 1

[0081] (1) Add 37.09kg of TiCl to the first reactor 4 17.35kg of NaOH solution (wherein TiCl 4 : The molar ratio of NaOH is 1:1), which promotes TiCl 4 Carry out the first contact reaction with NaOH at a temperature of 40°C (water bath temperature control) for 50 minutes. After the reaction is completed, the first contact product is left to stand for 1 hour to obtain a sol-like first mixture. It can be known that the first mixture The pH value is 8.5;

[0082] (2) Add 37.09kg of TiCl in the second reactor 4 , and under agitation, in this second reactor, dropwise adding concentration is the hydrochloric acid 4.6kg (wherein TiCl 4 : The molar ratio of HCl is 1: 0.2), which promotes TiCl 4 Carry out the second contact reaction with hydrochloric acid at a temperature of 40° C. (water bath temperature control), and react for 15 minutes to obtain the second mixture;

[0083] (3) Inject the sol (first mixture) obtained in step (1) into the second reaction kettle with the second ...

Embodiment 2

[0085] (1) Add 30kg of TiCl in the first reactor 4 , under agitation, in this first reactor, dropwise concentration is the NaOH solution 11.25kg (wherein TiCl 4 : The molar ratio of NaOH is 1:0.8), which promotes TiCl 4 Carry out the first contact reaction with NaOH at a temperature of 30°C (water bath temperature control) for 60 minutes; after the reaction is completed, let the contact product of the first contact stand for 1 hour to obtain a sol-like first mixture, which can be known by measurement The pH value is 8;

[0086] (2) Add 30kg of TiCl in the second reactor 4, and under agitation, in this second reactor, dropwise adding concentration is the hydrochloric acid 2.79kg of 31wt% (wherein TiCl 4 : The molar ratio of HCl is 1:0.15), which promotes TiCl 4 Carry out the second contact reaction with hydrochloric acid at a temperature of 30° C. (water bath temperature control), and react for 30 minutes to obtain the second mixture;

[0087] (3) Inject the sol (first mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com