A kind of preparation method and application of high-quality coarse grain WC powder

A coarse-grained, high-quality technology, applied in the direction of tungsten/molybdenum carbides, carbides, etc., it can solve the problems of general particle size uniformity, difficult to meet production needs, poor grain development consistency, etc., and achieve good particle size distribution. , the effect of reducing the preparation cost and excellent overall performance of the alloy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

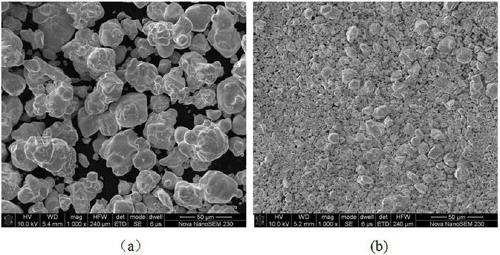

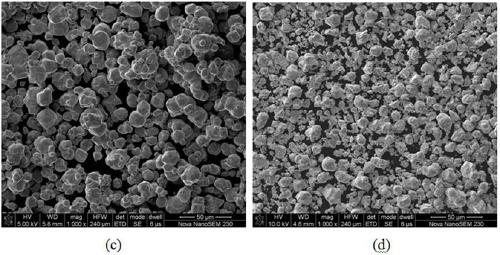

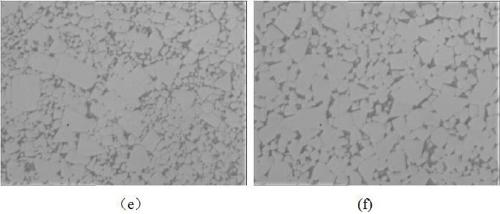

Image

Examples

preparation example Construction

[0032] The preparation method of the high-quality coarse-grained WC powder of the present invention comprises the following steps:

[0033] S1. Put WO 2 powder in N 2 +H 2 A reduction is carried out in a mixed atmosphere to obtain coarse-grained WO 3 powder particles; in pure H 2 Carry out secondary reduction in the atmosphere to prepare coarse-grained W powder, and the FSSS particle size of W powder is 12-16 μm;

[0034] S2. The coarse-grained tungsten powder obtained in step S1 is subjected to a pre-mixing process, C black is added for mixing to prepare carbon, and then pressed, and the WC material is obtained by carbonizing at a high temperature of 1900-2300 °C;

[0035] S3. The WC material is crushed and sieved, and the measured FSSS particle size is 13-17 μm, and the FSSS particle size is 5.5-7.0 μm, and the high-quality coarse-grained WC powder with oxygen content of 0.01%-0.02% is ground; wherein, the N in step S1 2 +H 2 N in mixed atmosphere 2 with H 2 The volu...

Embodiment 1

[0037] The preparation method of the high-quality coarse-grained WC powder of the present embodiment comprises the following steps:

[0038] S1. Put WO 3 powder in N 2 +H 2 In a mixed atmosphere, N 2 :H 2 The volume ratio is 1:1, and a reduction is carried out in a tubular reduction furnace. The reduction temperature is 960 °C, and the N 2 +H2 The flow rate of the mixed atmosphere is 15m 3 / h, the loading capacity of the boat is 8kg, and the thrust speed is 40min / boat; the coarse-grained WO is obtained 3 Powder particles; the resulting coarse-grained WO 3 The powder particles are sieved twice, the first time is 80 mesh, and the second time is 120 mesh. The resulting product is WO 3 , FSSS particle size is about 16μm.

[0039] The WO obtained by the one-time reduction 3 batch, in pure H 2 The secondary reduction was carried out under the atmosphere. Reduction temperature 970℃, H 2 The flow rate of the atmosphere is 10m 3 / h, dew point: -60℃, loading capacity 6kg, ...

Embodiment 2

[0044] The preparation method of the high-quality coarse-grained WC powder of the present embodiment comprises the following steps:

[0045] S1. Put WO 2 The powder is placed in a mixed atmosphere of N2+H2, N2 2 :H 2 The volume ratio is 1:2, and a reduction is carried out in a tubular reduction furnace at a reduction temperature of 980 °C, N 2 +H 2 The flow rate of the mixed atmosphere is 12m 3 / h, the loading capacity of the boat is 6kg, and the pushing speed is 35min / boat; the coarse-grained WO is obtained 3 Powder particles; the resulting coarse-grained WO 3 The powder particles are sieved twice, the first time is 80 mesh, and the second time is 120 mesh. The resulting product is WO 3 , FSSS particle size is about 14.5μm;

[0046] The WO obtained by the one-time reduction 3 batch, in pure H 2 The secondary reduction was carried out under the atmosphere. Reduction temperature 1000℃, H 2 The flow rate of the atmosphere is 12m 3 / h, dew point: -60℃, loading capaci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com