A method for preparing composite oil nanoemulsion by low temperature dissolution of phospholipid-microfluidic technology

A low-temperature dissolving and compound oil technology, which is applied in the field of medicine, can solve the problems of active oxidative substances affecting the physiological function of the liver, increasing the content of aspartate aminotransferase, and abnormal metabolism of liver enzymes, so as to improve the uniformity of particle size distribution and reduce oxidation and hydrolysis. , to avoid the effect of phospholipid oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

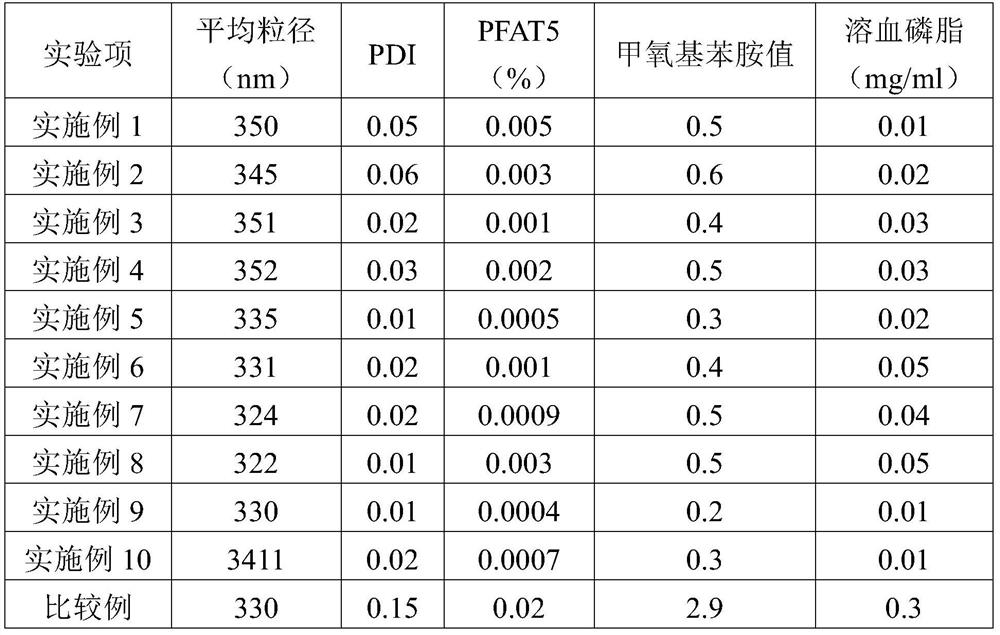

Embodiment 1

[0062] Take 60g of refined soybean oil, 60g of medium-chain triglycerides, 50g of refined olive oil, 30g of purified fish oil and 135mg of dl-α-tocopherol, add them to No. 1 pressure-resistant preparation tank, and take the egg yolk Add 12 grams of phospholipids to it, preheat the cavity of the tank to 30° C., fill the tank with carbon dioxide gas until the pressure in the cavity is 7 MPa, and disperse the phospholipids in the mixed oil to obtain an oil phase. In No. 2 preparation tank, 25 grams of glycerin, 300 mg of sodium oleate and 10 ml of sodium hydroxide solution (2 mg / ml) were dissolved in 763 g of water for injection to prepare an aqueous phase (pH of 9.8 to 11.5), heated to 30°C. Then, the water phase is added to the oil phase, and the stator rotor type shearing machine is used for shear dissolution to prepare colostrum. After that, slowly release the gas in the No. 1 preparation tank to restore the pressure in the tank to normal atmospheric pressure. The original c...

Embodiment 2

[0064] Take 60g of refined soybean oil, 60g of medium-chain triglycerides, 50g of refined olive oil, 30g of purified fish oil and 135mg of dl-α-tocopherol, add them to No. 1 pressure-resistant preparation tank, and take the egg yolk Add 12 grams of phospholipids to it, preheat the cavity of the tank to 30° C., fill the tank with carbon dioxide gas until the pressure in the cavity is 7.5 MPa, and disperse the phospholipids in the mixed oil to obtain an oil phase. In No. 2 preparation tank, 25 grams of glycerin, 300 mg of sodium oleate and 10 ml of sodium hydroxide solution (2 mg / ml) were dissolved in 763 g of water for injection to prepare an aqueous phase (pH of 9.8 to 11.5), heated to 30°C. Then, the water phase is added to the oil phase, and the stator rotor type shearing machine is used for shear dissolution to prepare colostrum. After that, slowly release the gas in the No. 1 preparation tank to restore the pressure in the tank to normal atmospheric pressure. The original...

Embodiment 3

[0066] Take 60g of refined soybean oil, 60g of medium-chain triglycerides, 50g of refined olive oil, 30g of purified fish oil and 135mg of dl-α-tocopherol, add them to No. 1 pressure-resistant preparation tank, and take the egg yolk Add 12 grams of phospholipids to it, preheat the cavity of the tank to 31° C., fill the tank with carbon dioxide gas until the pressure in the cavity is 7.2 MPa, and disperse the phospholipids in the mixed oil to obtain an oil phase. In No. 2 preparation tank, 25 grams of glycerin, 300 mg of sodium oleate and 10 ml of sodium hydroxide solution (2 mg / ml) were dissolved in 763 g of water for injection to prepare an aqueous phase (pH 9.8 to 11.5), heated to 31° C. Then, the water phase is added to the oil phase, and the stator rotor type shearing machine is used for shear dissolution to prepare colostrum. After that, slowly release the gas in the No. 1 preparation tank to restore the pressure in the tank to normal atmospheric pressure. The original c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com