A kind of preparation method of herbicide saponin

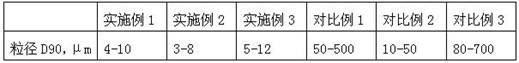

A technology of sedge phosphorus and herbicide, which is applied in the field of preparation of herbicide sedge phosphate, can solve the problems of large particle size and uneven particle size distribution of the original drug of sedge phosphate, achieves safety and environmental protection in the preparation process, and improves the purity and yield. , to avoid the effect of the grinding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of herbicide saponin, specifically:

[0031] 1. Preparation of hollow microspheres: place X-type porous zeolite powder in a calcination furnace, control the temperature of the calcination furnace to 350°C, and obtain calcined X-type porous zeolite powder after calcination for 2 hours, and place 10 g of calcined X-type porous zeolite powder Zeolite powder is mixed with 35g of absolute ethanol, 1g of dimethyl diallyl ammonium chloride aqueous solution, 3g of acetic acid, and 1g of nickel nitrate before ultrasonic dispersion. The frequency of ultrasonic dispersion is controlled at 20kHz, and the time of ultrasonic dispersion is 20min. After the end, the dispersed raw material is obtained; the dispersed raw material is cooled to -20°C, frozen at -20°C for 30 minutes, then slowly heated to 90°C, and the temperature rise rate is controlled at 2°C / min, and the temperature is raised to 90°C to obtain The raw material after freezing treatment; then control t...

Embodiment 2

[0038] A preparation method of herbicide saponin, specifically:

[0039] 1. Preparation of hollow microspheres: Place X-type porous zeolite powder in a calciner, control the temperature of the calciner to 370°C, and calcined for 2.5 hours to obtain calcined X-type porous zeolite powder. The porous zeolite powder is mixed with 37g of absolute ethanol, 1.5g of dimethyl diallyl ammonium chloride aqueous solution, 4g of acetic acid, and 1.5g of nickel nitrate before ultrasonic dispersion. The frequency of ultrasonic dispersion is controlled at 25kHz, and the time of ultrasonic dispersion is 25min. , after the ultrasonic dispersion, the dispersed raw material was obtained; the dispersed raw material was cooled to -15°C, frozen at -15°C for 35 minutes, and then slowly raised to 95°C, controlled at a heating rate of 2.5°C / min, and then heated to 95 ℃, to obtain the raw material after freezing treatment; then control the temperature to 95 °C and stir the raw material after freezing tr...

Embodiment 3

[0046] A preparation method of herbicide saponin, specifically:

[0047] 1. Preparation of hollow microspheres: place X-type porous zeolite powder in a calciner, control the temperature of the calciner to 400°C, and obtain calcined X-type porous zeolite powder after calcining for 3 hours, and place 12 g of calcined X-type porous zeolite Zeolite powder is mixed with 40g of absolute ethanol, 2g of dimethyl diallyl ammonium chloride aqueous solution, 5g of acetic acid, and 2g of nickel nitrate before ultrasonic dispersion. The frequency of ultrasonic dispersion is controlled at 30kHz, and the time of ultrasonic dispersion is 30min. After the end, the dispersed raw material is obtained; the dispersed raw material is cooled to -10°C, frozen at -10°C for 40 minutes, then slowly heated to 100°C, and the heating rate is controlled to be 3°C / min, and the temperature is raised to 100°C to obtain Freezing the treated raw material; then controlling the temperature to 100° C. and stirring ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com