A method for improving the performance of carbon black filled rubber by electron beam irradiation modification of carbon black

A technology of electron beam irradiation and rubber filling, applied in the direction of fibrous filler, dyeing physical treatment, etc., can solve the problems of environmental pollution and harmful rubber performance, and achieve the effect of less environmental pollution, low cost, mature and stable technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Modification method of N234 irradiation:

[0033] Put 150g N234 evenly in a sealed glass box, the current of the electron beam irradiation device is 10mA, the voltage is 10MeV, and the irradiation dose is 300kGy to 500kGy.

[0034]

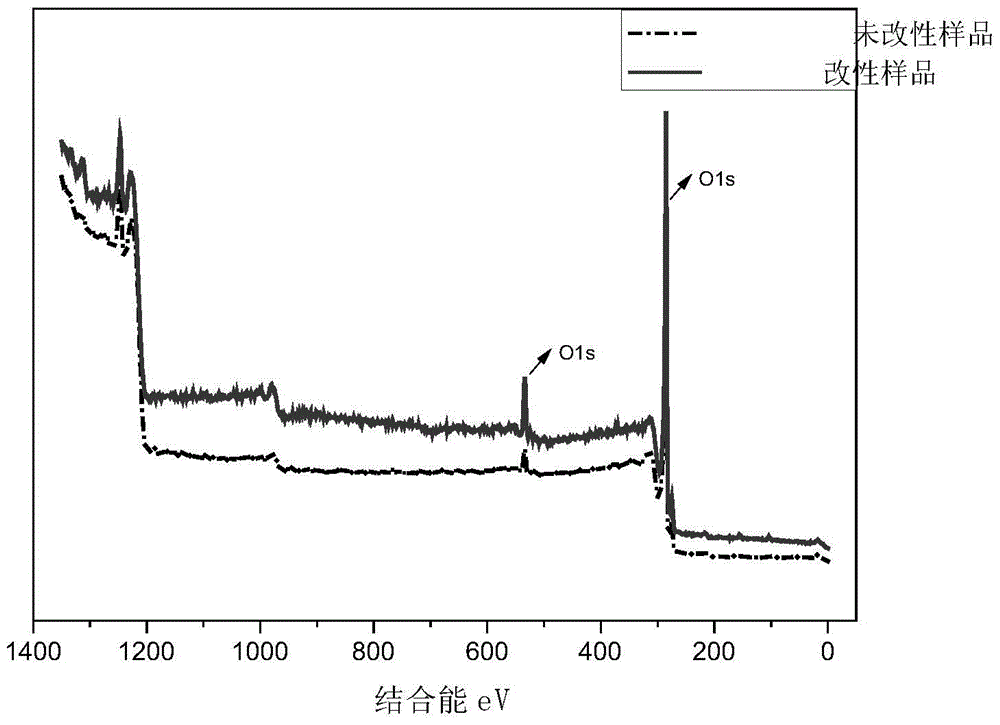

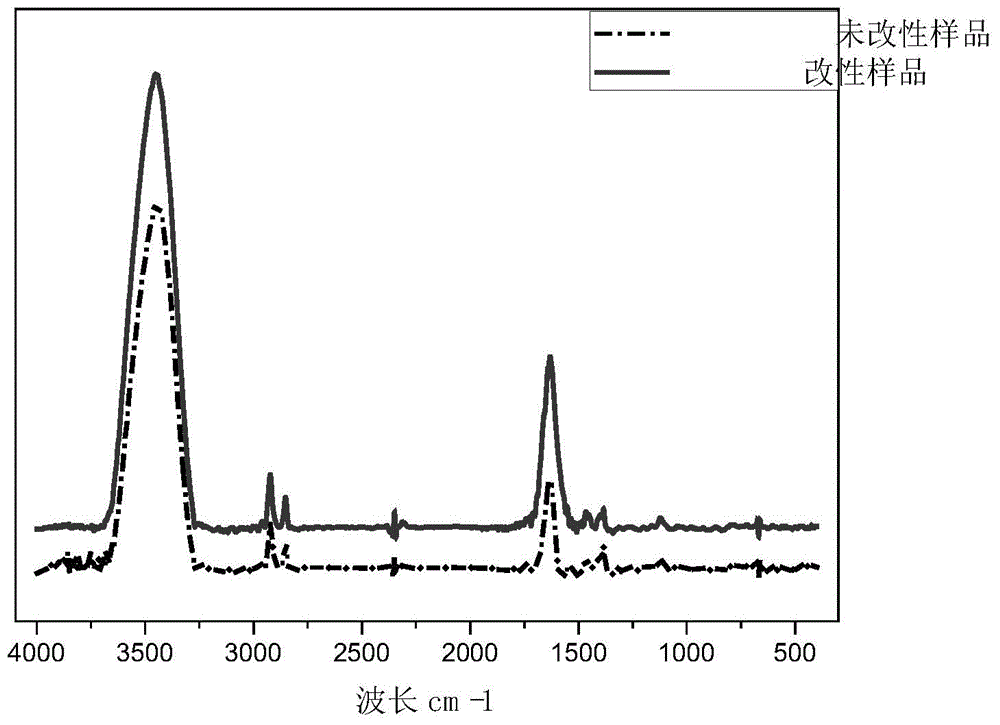

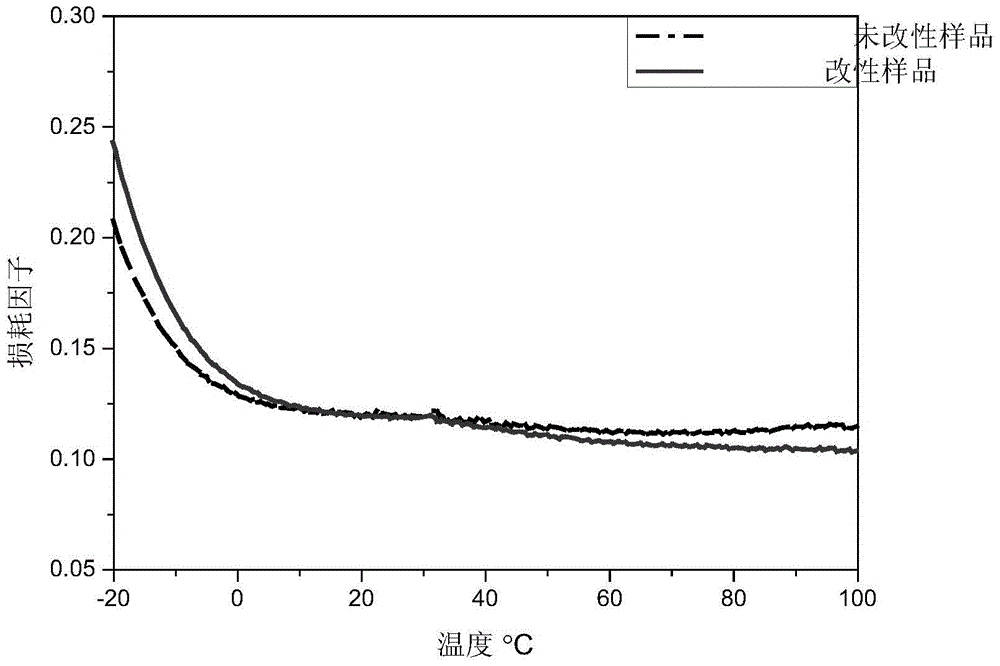

[0035] It can be seen from Table 1 that when N234 is modified with an irradiation dose of 300kGy to 500kGy, the oxygen element content on the surface of carbon black increases by 89%. The resulting defects react with oxygen molecules or oxygen free radicals (generated by high-energy electron beam radiation) on the surface of carbon black, which increases the oxygen-containing functional groups on the surface of carbon black

[0036]

[0037] It can be seen from Table 2 that when the irradiation dose of N234 is modified from 300kGy to 500kGy, the specific surface area increases, the average particle size of carbon black decreases and the uniformity of particle size distribution becomes better. Due to the bombardment of high-energy elect...

Embodiment 2

[0041] Irradiation modified N330:

[0042] Place 150g N330 evenly in a sealed glass box, the current of the electron beam irradiation device is 10mA to 20mA, the voltage is 10MeV to 30MeV, and the irradiation dose is 200kGy to 400kGy.

[0043]

[0044] It can be seen from Table 4 that the surface oxygen content of N330 increased by 52.3% after being modified by electron beam irradiation. This is due to the fact that during the irradiation process, the high-energy electron beam bombards the carbon black, causing the defects on the surface of the carbon black to react with the oxygen molecules or oxygen free radicals (generated due to the high-energy electron beam radiation) on the surface of the carbon black, making the carbon black The oxygen-containing functional groups on the black surface increased.

[0045]

[0046]

[0047] It can be seen from Table 5 that the specific surface area of N330 increases after being modified by electron beam irradiation, the averag...

Embodiment 3

[0051] Modification method of N660 electron beam irradiation:

[0052] Place 150g N660 evenly in a sealed glass box, the current of the electron beam irradiation device is 20mA to 40mA, the voltage is 8MeV to 40MeV, and the irradiation dose is 200kGy to 00kGy.

[0053]

[0054] It can be seen from Table 7 that the surface oxygen content of N660 increased by 106.9% after electron beam irradiation modification. This is due to the fact that during the irradiation process, the high-energy electron beam bombards the carbon black, causing the defects on the surface of the carbon black to react with the oxygen molecules or oxygen free radicals (generated due to the high-energy electron beam radiation) on the surface of the carbon black, making the carbon black The oxygen-containing functional groups on the black surface increased.

[0055]

[0056] It can be seen from Table 8 that the specific surface area of N660 increases after being modified by electron beam irradiation, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com