Modified fluorine-containing resin coating, and preparation and use method thereof

A technology of fluorine-containing resin and tetrafluoroethylene resin, applied in anti-corrosion coatings, coatings, etc., can solve problems such as VOC emissions, high cost, and complicated operation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

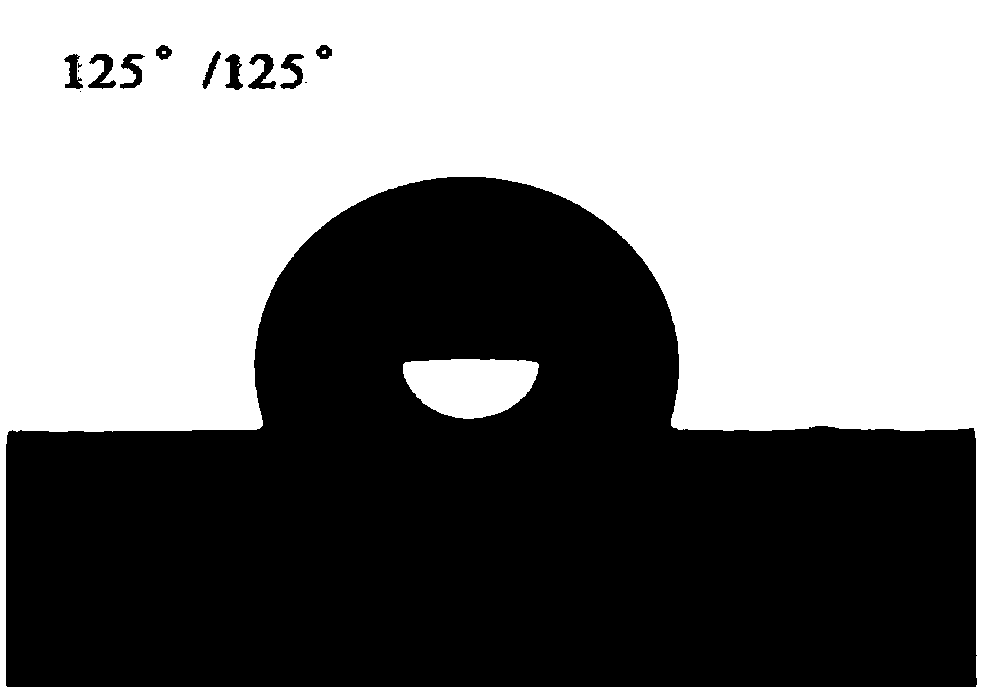

[0029] The modified fluorine-containing resin coating is composed of the following components in parts by weight: 80 parts of modified fluorine-containing resin, 1 part of polyamide wax micropowder, 0.1 part of attapulgite, 2 parts of nano-titanium dioxide, and 2 parts of nano-silica; The weight ratio of modified polytetrafluoroethylene resin, modified polyethylene-tetrafluoroethylene resin and modified polyvinylidene fluoride resin in the permanent fluorine-containing resin is 1:2:1.

[0030] The preparation method of modified fluorine-containing resin is:

[0031] Step 1: Mix fluorine-containing resin (polytetrafluoroethylene resin, polyethylene-tetrafluoroethylene resin and polyvinylidene fluoride resin) according to the above ratio, place in an oven at 120°C, and dry; place the dried fluorine-containing resin in In a high-voltage corona treatment machine, corona treatment is carried out;

[0032] Step 2: Add the fluorine-containing resin obtained above into the reactor, a...

Embodiment 2

[0037] The modified fluorine-containing resin coating is composed of the following components in parts by weight: 100 parts of modified fluorine-containing resin, 5 parts of polyamide wax micropowder, 1 part of attapulgite, 3 parts of nano-titanium dioxide, and 3 parts of nano-silica; The weight ratio of modified polytetrafluoroethylene resin, modified polyethylene-tetrafluoroethylene resin and modified polyvinylidene fluoride resin in the permanent fluorine-containing resin is 1:3:1.

[0038] The preparation method of modified fluorine-containing resin is:

[0039] Step 1: Mix fluorine-containing resin (polytetrafluoroethylene resin, polyethylene-tetrafluoroethylene resin and polyvinylidene fluoride resin) according to the above ratio, place in an oven at 120°C, and dry; place the dried fluorine-containing resin in In a high-voltage corona treatment machine, corona treatment is carried out;

[0040] Step 2: Add the fluorine-containing resin obtained above into the reactor, a...

Embodiment 3

[0045] The modified fluorine-containing resin coating is composed of the following components in parts by weight: 150 parts of modified fluorine-containing resin, 5 parts of polyamide wax micropowder, 2 parts of attapulgite, 5 parts of nano-titanium dioxide, and 5 parts of nano-silica; The weight ratio of modified polytetrafluoroethylene resin, modified polyethylene-tetrafluoroethylene resin and modified polyvinylidene fluoride resin in the permanent fluorine-containing resin is 1.5:4:0.5.

[0046] The preparation method of modified fluorine-containing resin is:

[0047] Step 1: Mix fluorine-containing resin (polytetrafluoroethylene resin, polyethylene-tetrafluoroethylene resin and polyvinylidene fluoride resin) according to the above ratio, place in an oven at 120°C, and dry; place the dried fluorine-containing resin in In a high-voltage corona treatment machine, corona treatment is carried out;

[0048] Step 2: Add the fluorine-containing resin obtained above into the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com