Magnesium valproate sustained release tablet and preparation process thereof

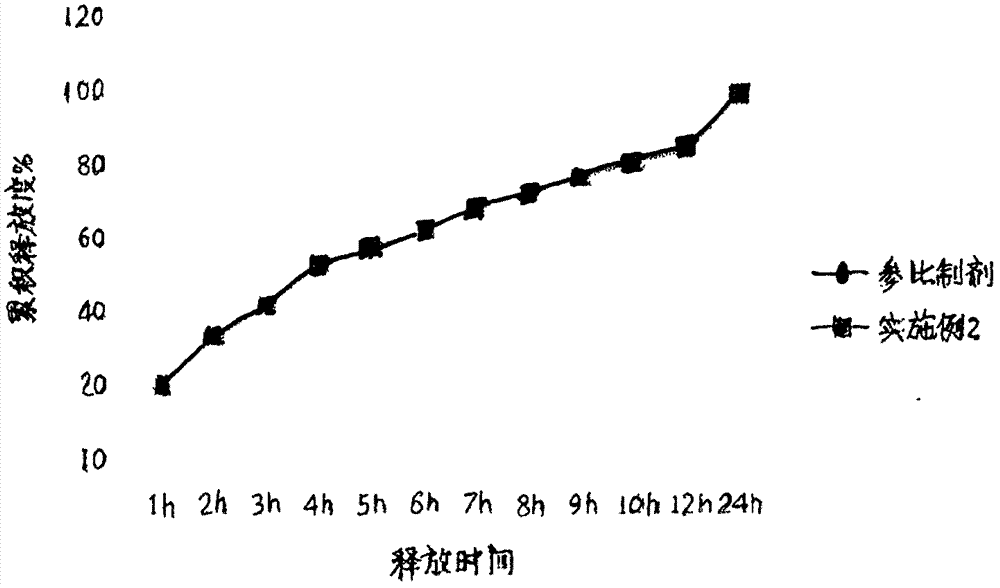

A magnesium valproate, preparation technology, applied in anhydride/acid/halide active ingredients, coatings, pill delivery, etc., can solve the problems of patients who are difficult to persist for a long time, high peak blood concentration, and large fluctuations in blood concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

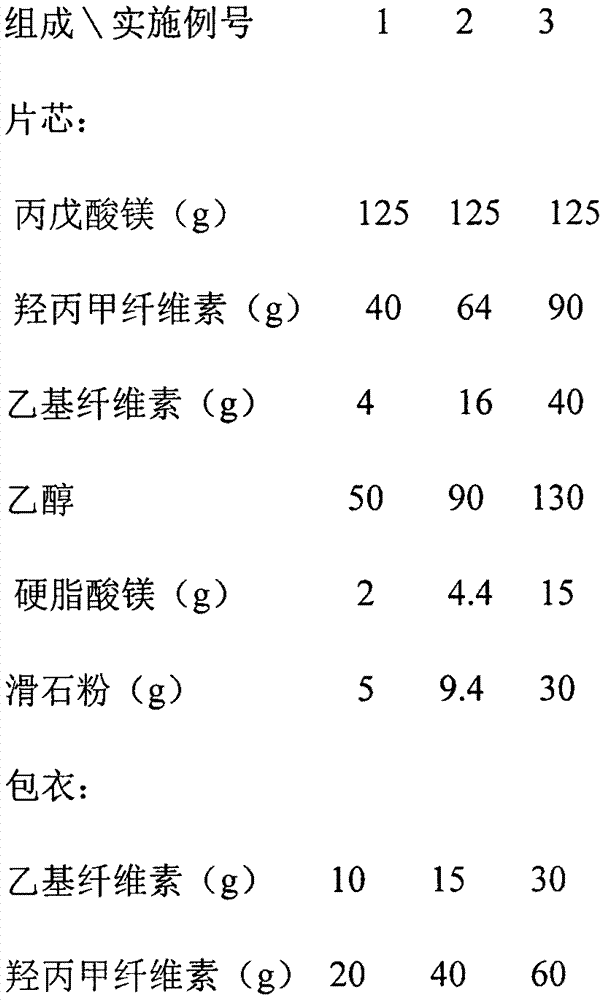

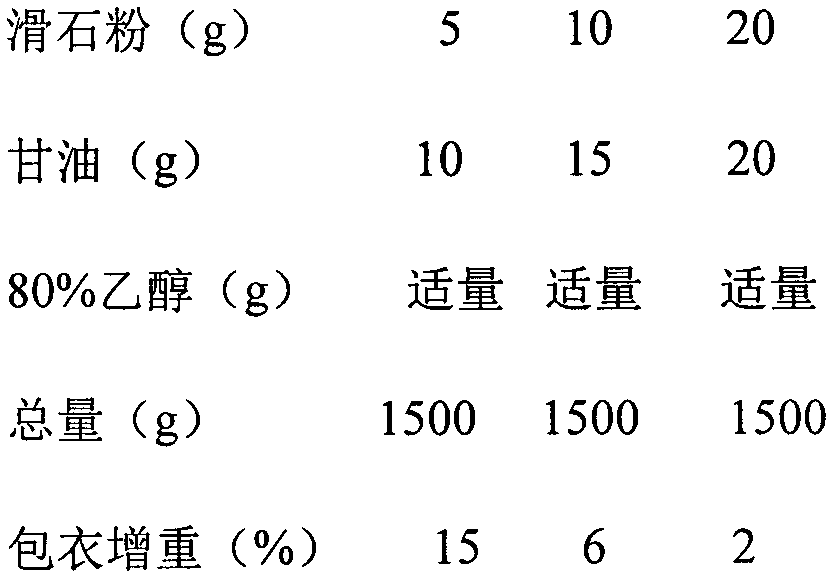

[0026] Example: 1000 tablets

[0027]

[0028]

[0029] Preparation method: crush magnesium valproate and pass through an 80-mesh sieve for later use; pass hypromellose, ethyl cellulose and magnesium stearate through a 100-mesh sieve for later use; Add an appropriate amount of ethanol to make a soft material, granulate through a 24-mesh sieve, then dry at a temperature of 55°C-65°C, sieve through a 24-mesh granule, and then add magnesium stearate, talc powder (or micro-powder silica gel) to mix After uniformity, measure the content, calculate the weight of the tablet, and press it into an oval tablet with a hardness of 40N-70N. Finally, the coating solution prepared from the above coating materials is used for coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com