A patterned polymer and its preparation method

A patterning and polymer technology, applied in polyether coatings, polyester coatings, coatings, etc., can solve the problems of uncontrollable pattern structure, small patterned area, high equipment cost, etc., and achieve regular and controllable pattern structure. Strong adaptability and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

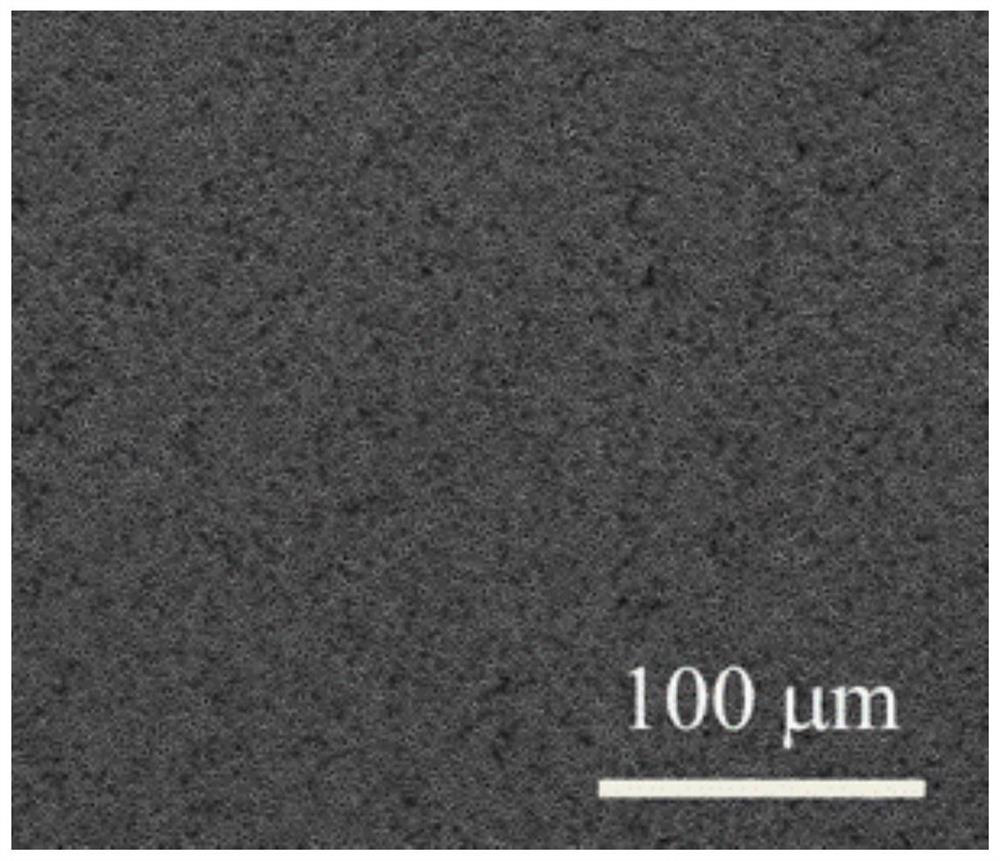

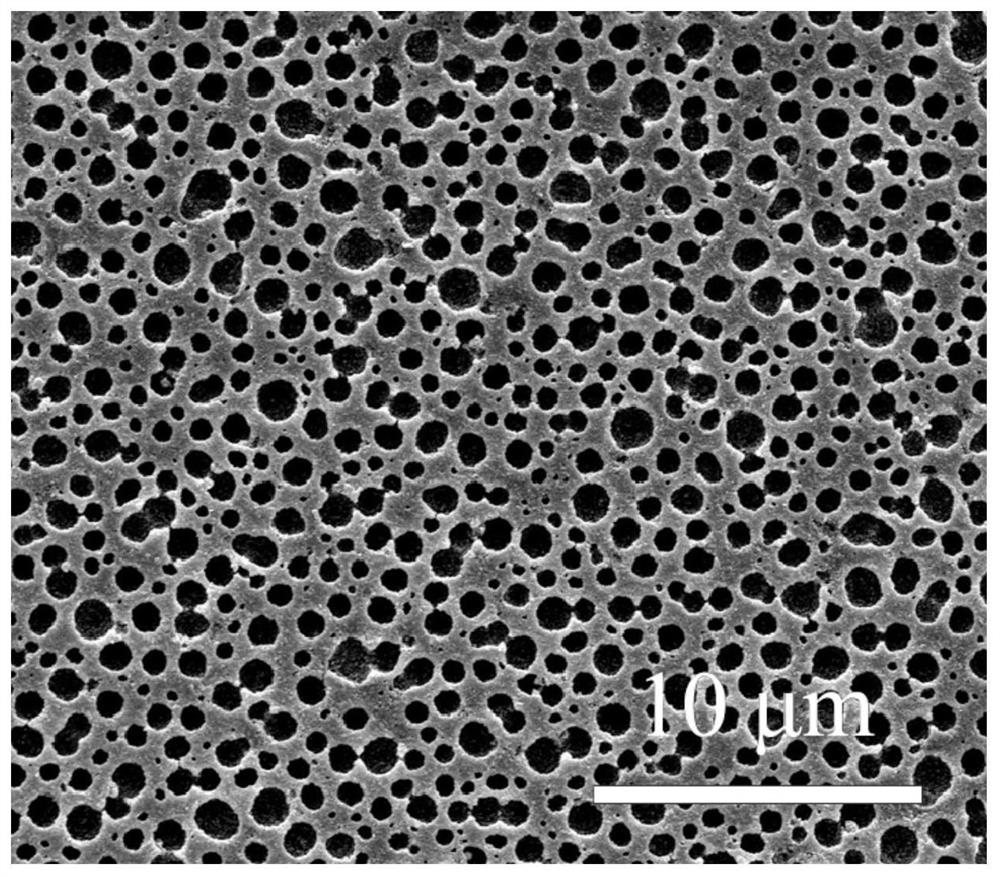

[0065]Patterned polymer layered materials

[0066]The patterned polymer layered material has a three-layer laminated structure, which is a polyethylene polymer substrate layer, a polypropylene and silica 80:20 patterned structure layer, and a polyacrylic acid surface encapsulation layer. The patterned structure layer has a dispersed bowl-shaped convex structure. The surface encapsulation layer is a continuous thin layer covering the surface of the patterned structure layer and retains the shape of the patterned structure layer.

Embodiment 2

[0068]Prepare inorganic nanoparticles pretreated by coupling agent

[0069]The inorganic nanoparticles are pre-soaked in a coupling agent with a mass concentration of 0.1-5.0% for 5-60 minutes, and then dried at a temperature of 20-90° C. for 5-60 minutes to obtain inorganic nanoparticles modified by the coupling agent for use. The specific preparation materials and parameters are as follows:

[0070]

[0071]

Embodiment 3

[0073]Preparation of patterned polymer layered materials

[0074]Prepare the patterned polymer layered material according to the following steps:

[0075]Step (1) In the process of cleaning the polyethylene substrate layer, the substrate is soaked in ethanol for 10 minutes, then dried at 30°C for 60 minutes; then soaked in deionized water for 10 minutes, and then dried at 30°C for 60 minutes. Then treated with low temperature plasma for 10s.

[0076]Step (2) Mix the second polymer polypropylene with a molecular weight of 5000 g / mol and the inorganic nanoparticles treated with the coupling agent numbered 201 in Example 2 in a mass ratio of 90:10, and prepare with (second solvent) toluene A solution with a mass concentration of 30.0%. Then, it is coated on the polymer substrate layer pretreated in step (1) by dipping for 10 seconds, and then taken out.

[0077]In step (3), the polymer substrate layer coated in step (2) is treated at a temperature of 30° C. and a relative humidity of 90% for 30 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com