Soil cadmium passivator and processing method thereof

A passivating agent and soil technology, which is applied in the restoration of heavy metal-contaminated soil in farmland, and in the field of repairing heavy metal-contaminated soil in farmland, can solve the problems of long bioremediation cycle, damage to farmers' income, and reduce the bioavailability and mobility of heavy metal pollutants. Achieve the effects of reducing the content of available cadmium, reducing the content of available Cd, and improving utilization and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

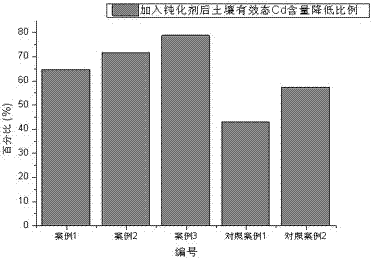

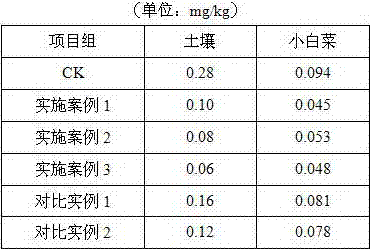

Embodiment example 1

[0050] The raw materials of the passivator collected and prepared include the following components according to the weight ratio: 25 bentonite, 10 lime, 20 ferric chloride, 30 decomposed straw, and 15 phosphate fertilizer; among them, bentonite and lime are purchased from the market in Wuhan City, Hubei Province, and the source of decomposed straw In the abandoned crops in Jingmen City, diammonium phosphate and ferric chloride are chemically pure reagents for phosphate fertilizer. The above raw materials are dried in the sun, pulverized and sieved to 20 meshes through a standard sieve to obtain granular raw materials, which are uniformly mixed to obtain a soil cadmium passivator.

Embodiment example 2

[0052] The raw materials of the passivator collected and prepared include the following components according to the weight ratio: 20 bentonite, 10 lime, 20 ferric chloride, 35 decomposed straw, and 15 phosphate fertilizer; among them, bentonite and lime are purchased from the market in Wuhan City, Hubei Province, and decomposed straw comes from In the abandoned crops in Jingmen City, diammonium phosphate and ferric chloride are chemically pure reagents for phosphate fertilizer. The above raw materials are dried in the sun, pulverized and sieved to 20 meshes through a standard sieve to obtain granular raw materials, which are uniformly mixed to obtain a soil cadmium passivator.

Embodiment example 3

[0054] The raw materials of the passivator collected and prepared include the following components according to the weight ratio: 25 bentonite, 5 lime, 20 ferric chloride, 35 decomposed straw, and 15 phosphate fertilizer; among them, bentonite and lime are purchased from the market in Wuhan City, Hubei Province, and the source of decomposed straw In the abandoned crops in Jingmen City, diammonium phosphate and ferric chloride are chemically pure reagents for phosphate fertilizer. The above raw materials are dried in the sun, pulverized and sieved to 20 meshes through a standard sieve to obtain granular raw materials, which are uniformly mixed to obtain a soil cadmium passivator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com