Method and device for quenching red coke in coking industry

A technology of coke quenching and coke application in the field of energy and energy recovery and environmental protection, which can solve the problems that equipment investment and operation stability cannot meet the requirements of coke quenching operation, and achieve simple water spray equipment and operation, fast opening and closing, The effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

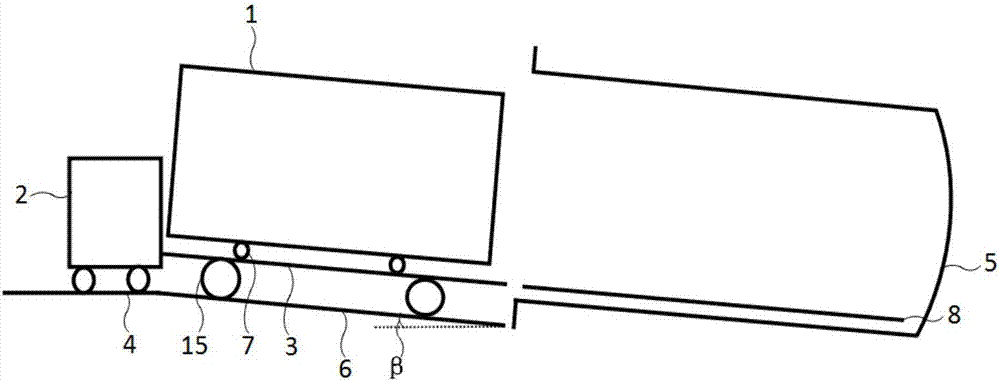

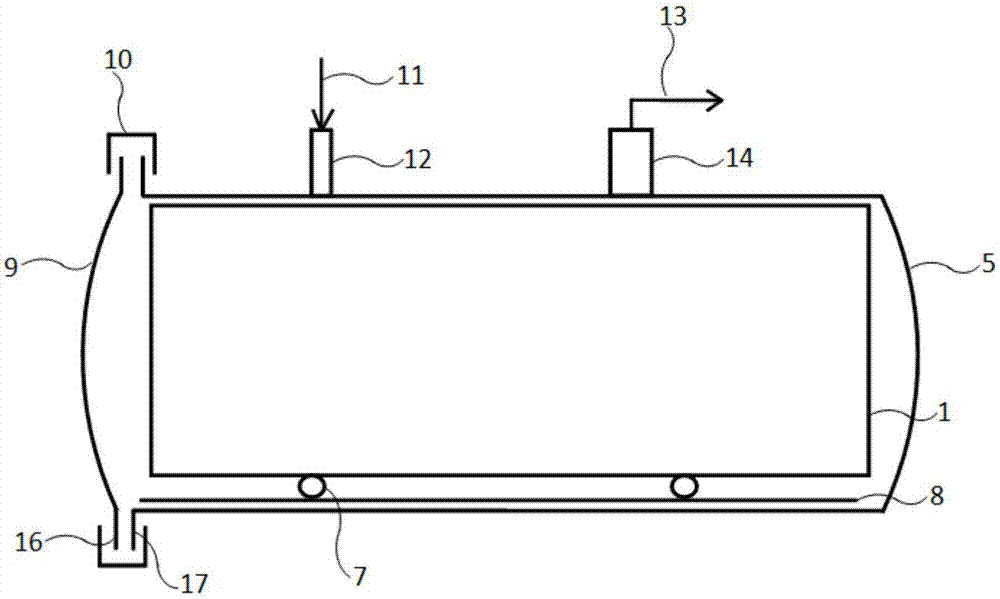

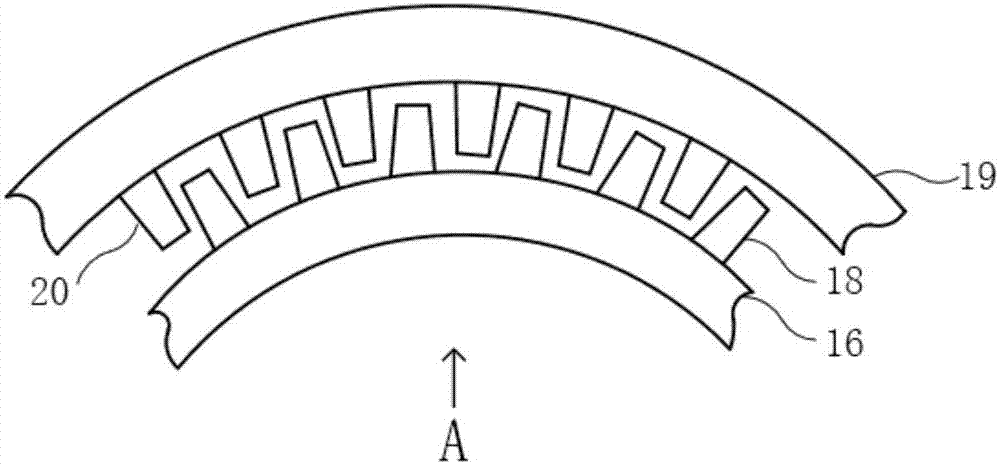

[0043] This embodiment is a coke quenching process scheme for red coke by spraying water in a closed chamber to vaporize and cool down. The red coke pushed out from the coking chamber of the coke oven is loaded into the coke transport tank 1 and then pushed by the coke transport power vehicle 2 through the transport vehicle 3 to move it to the coke quenching tank 5 through the coke transport track 4 . Carrier wheel 15 enters inclined track 6 (as figure 1 As shown), the inclination formed enables the coke transport tank 1 to enter the quenching tank 5 along the tank inner track 8 through the coke transport tank roller 7 . Afterwards, the tank cover 9 is rotated to make the tank cover flange 16 contact with the coke quenching tank inlet and outlet flange 17, and the airtight cover is locked by the tank cover locking mechanism 10 (such as figure 2 shown), and inflate and pressurize the sealing ring to achieve sealing, so as to achieve the purpose of isolating from the atmospher...

Embodiment 2

[0049] This embodiment is basically the same as Embodiment 1, except that the bottom of the coke transporting trough is provided with two parallel tracks (the coke transporting trough track 26) along the length direction, and the upper part of the carrier is provided with a turning roller (the turning roller 25 on the carrier car). ), correspondingly in the coke quenching tank is also provided with a turning roller (bottom turning roller 24 in the tank), the coke transport groove enters the coke quenching tank through the track at the bottom, turning the roller above the carrier vehicle and turning the stick track at the bottom of the coke quenching tank 5 and withdraw from the quenching tank, such as Figure 7 shown.

[0050] The locking mechanism of the quenching tank cover adopts the method of rotating the tank cover after the tank cover is inserted into the space between the flange teeth of the quenching tank entrance and exit, such as Figure 8 . The inlet and outlet fl...

Embodiment 3

[0053] This embodiment is basically the same as Embodiment 1, the difference is that the inlet and outlet flange of the quenching tank is a single-layer rack structure, the tank cover is a double-layer structure, and the tank cover is locked by moving the tank cover to move the quenching tank. The rack is embedded in the rack space of the tank cover, and rotated so that the rack of the tank cover overlaps with the rack at the entrance and exit flange of the quenching tank, so as to achieve the purpose of locking the entrance and exit flange of the quenching tank and its cover flange. The sealing ring is arranged on the lid of the coke quenching tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com