System and method for chlorinating vanadium-containing stone coals

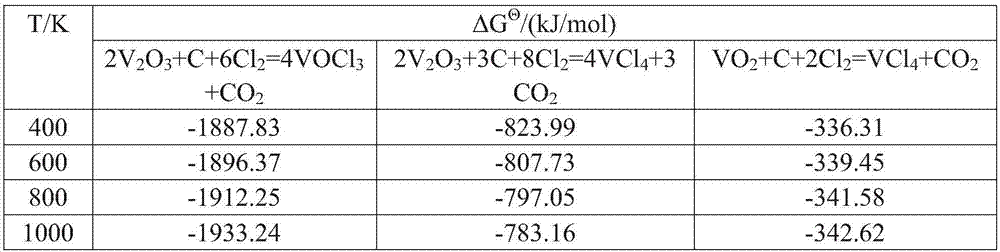

The technology of a chlorination system and vanadium stone is applied in the field of vanadium extraction process, which can solve the problems of impurity entry, complicated operation and high roasting energy consumption, and achieves the effects of high chlorination rate, improved economy and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

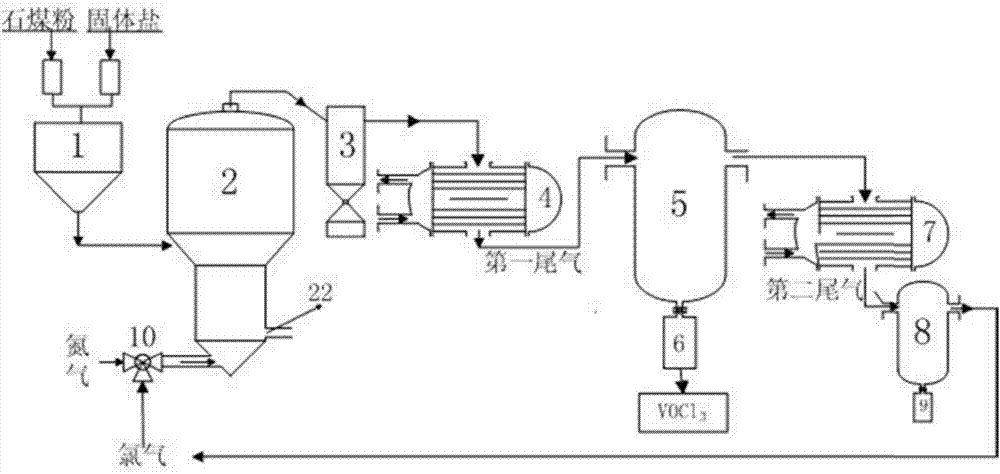

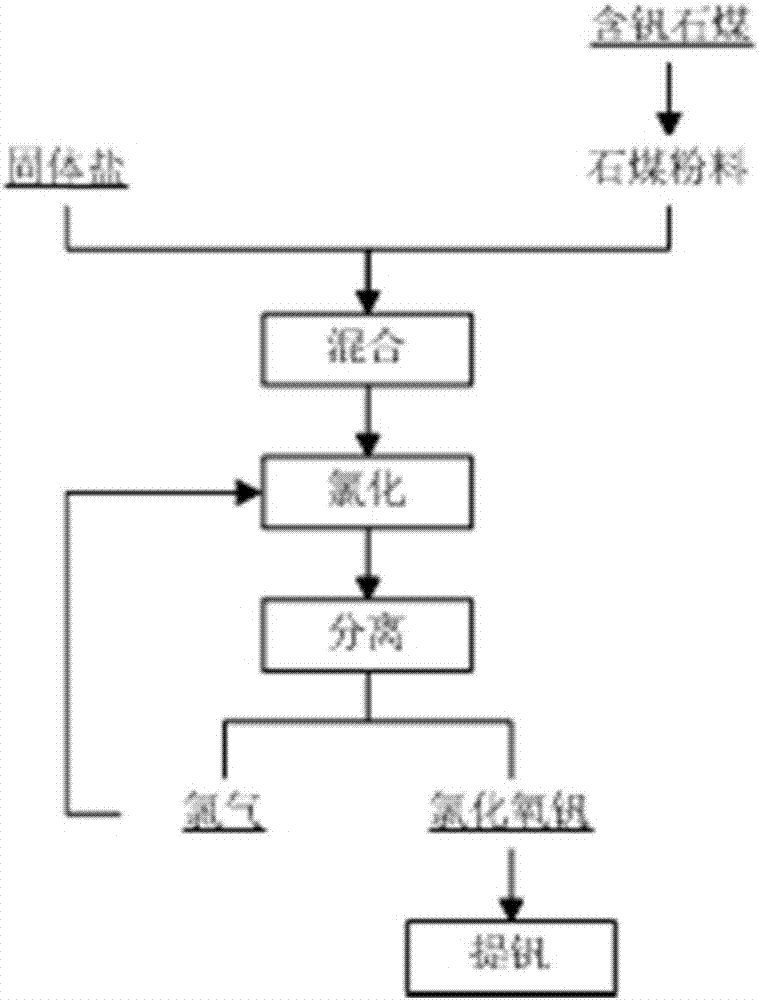

[0063] like Figure 1-2 Shown, provide a kind of method using the above-mentioned system chlorination vanadium-containing stone coal, comprise the following steps:

[0064] 1) Grinding and batching: stone coal powder is obtained by grinding vanadium-containing stone coal in a grinding device, and stone coal powder with a particle size below 0.1mm accounts for 80% of the total stone coal powder quality; the particle size is The ratio of the solid salt less than 0.1mm to the total solid salt mass is 90%; the stone coal powder and potassium chloride are mixed uniformly in the mixing silo 1 according to the mass ratio of 100:0.03 to form a mixture;

[0065] 2) Chlorination: Nitrogen gas is first introduced into the chlorination furnace 2, and when the partial pressure of nitrogen in the furnace is equal to the external atmospheric pressure, after heating the chlorination furnace for 2 to 450°C, the nitrogen gas is stopped and the chlorine gas is introduced, and the mixture is adde...

Embodiment 2

[0070] like Figure 1-2 Shown, provide a kind of method using the above-mentioned system chlorination vanadium-containing stone coal, comprise the following steps:

[0071] 1) Grinding and batching: stone coal powder is obtained by grinding vanadium-containing stone coal in a grinding device, and stone coal powder with a particle size below 0.1mm accounts for 80% of the total stone coal powder quality; the particle size is The ratio of the solid salt less than 0.1mm to the total solid salt mass is 90%; the stone coal powder and sodium chloride are mixed uniformly in the mixing bin 1 according to the mass ratio of 100:0.1 to form a mixture;

[0072] 2) Chlorination: Nitrogen gas is first introduced into the chlorination furnace 2, and when the partial pressure of nitrogen in the furnace is equal to the external atmospheric pressure, after heating the chlorination furnace for 2 to 600°C, the nitrogen gas is stopped and the chlorine gas is introduced, and the mixture is added to st...

Embodiment 3

[0077] like Figure 1-2 Shown, provide a kind of method using the above-mentioned system chlorination vanadium-containing stone coal, comprise the following steps:

[0078] 1) Grinding and batching: stone coal powder is obtained by grinding vanadium-containing stone coal in a grinding device, and stone coal powder with a particle size below 0.1mm accounts for 100% of the total stone coal powder quality; the particle size is The proportion of the solid salt less than 0.1mm in the total solid salt mass is 91%; the stone coal powder and solid salt (the solid salt is potassium chloride and sodium chloride are mixed according to the mass ratio of 1:1) according to the mass ratio of 100 : 0.05 is mixed uniformly into a mixture in the mixing silo 1;

[0079] 2) Chlorination: Nitrogen gas is first introduced into the chlorination furnace 2, and when the partial pressure of nitrogen in the furnace is equal to the external atmospheric pressure, after heating the chlorination furnace fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com